Slurry for silk-screen printing electrochemical etching as well as preparation method and application of slurry

A technology of screen printing and screen printing device is applied in the field of slurry for screen printing electrochemical etching and its preparation, which can solve the problems of etching, inability to achieve selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

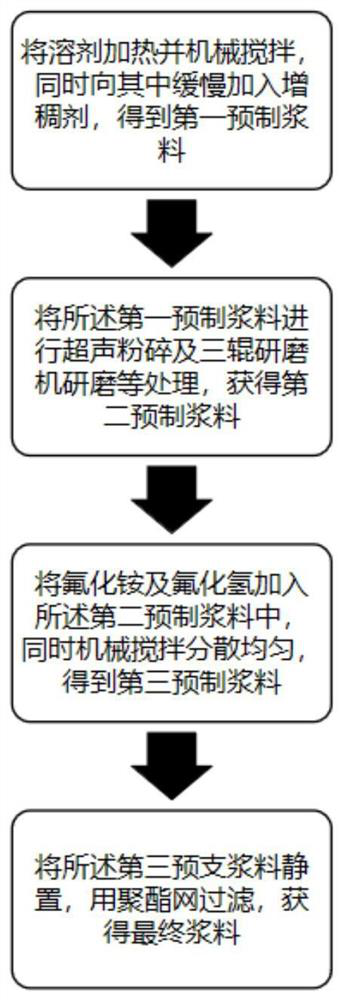

[0077] figure 1 It is a schematic diagram of the preparation method steps of the slurry described in the present invention, and the preparation method comprises the following steps: (1) mixing and stirring the thickener and the solvent to obtain the first prefabricated slurry; (2) preparing the prepared slurry obtained in step (1) The first prefabricated slurry is ultrasonically pulverized and ground to obtain a second prefabricated slurry; (3) mixing the second prefabricated slurry, ammonium fluoride and hydrogen fluoride obtained in step (2), stirring and dispersing to obtain a third prefabricated slurry (4) standing and filtering the third prefabricated slurry obtained in step (3) to obtain the slurry for screen printing electrochemical etching.

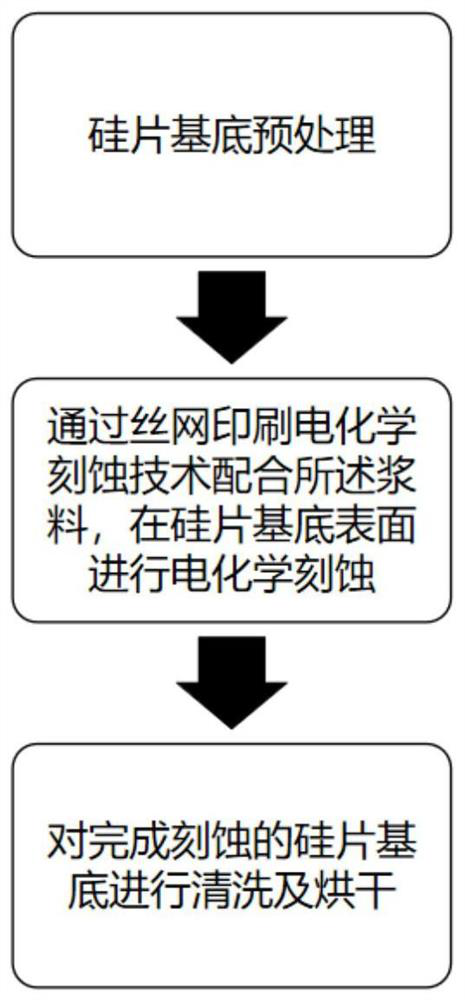

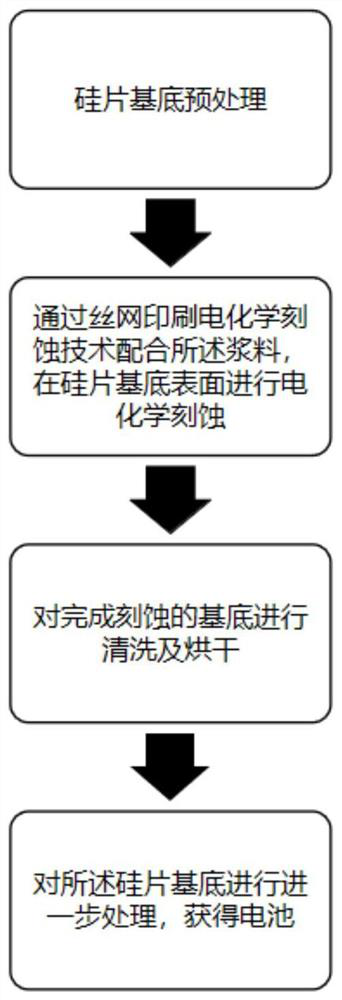

[0078] figure 2 It is a schematic diagram of the steps of the method for etching a silicon substrate with the slurry of the present invention and the electrochemical etching technology of screen printing, such as figure 2 As s...

Embodiment 1

[0086] This embodiment provides a slurry for screen printing electrochemical etching, the preparation method of the slurry for screen printing electrochemical etching includes the following steps:

[0087] (1) After preheating 93g of deionized water to 65°C, add 1.5g of xanthan gum and 1g of polyurethane thickener, and then stir at 500rpm for 20min at 65°C to obtain the first prefabricated slurry;

[0088] (2) Ultrasonic pulverizing the first prefabricated slurry obtained in step (1) for 10 minutes at a power of 1000W, and then grinding with a three-roll mill to obtain a second prefabricated slurry with a particle size of 1-20 μm;

[0089] (3) Mix the second prefabricated slurry obtained in step (2), 3 g of ammonium fluoride and 1.5 g of hydrofluoric acid, and stir at 25° C. at a speed of 200 rpm for 30 minutes to obtain a third prefabricated slurry;

[0090] (4) The third prefabricated slurry obtained in step (3) was left to stand at 25° C. for 30 minutes, and filtered throug...

Embodiment 2

[0092] This embodiment provides a slurry for screen printing electrochemical etching, the preparation method of the slurry for screen printing electrochemical etching includes the following steps:

[0093] (1) After preheating 94g of deionized water to 65°C, add 1g of xanthan gum and 1g of polyurethane thickener, and stir at 500rpm for 20min at 65°C to obtain the first prefabricated slurry;

[0094] (2) Ultrasonic pulverizing the first prefabricated slurry obtained in step (1) for 10 minutes at a power of 1000W, and then grinding with a three-roll mill to obtain a second prefabricated slurry with a particle size of 1-20 μm;

[0095] (3) Mix the second prefabricated slurry obtained in step (2), 2 g of ammonium fluoride and 2 g of hydrofluoric acid, and stir at 25° C. at a speed of 200 rpm for 30 min to obtain a third prefabricated slurry;

[0096] (4) The third prefabricated slurry obtained in step (3) was left to stand at 25° C. for 30 minutes, and filtered through a polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Etching depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com