Oil-water spraying device of rubber-tyred road roller and rubber-tyred road roller

A technology of a rubber wheel road roller and a spraying device, which is applied to the spraying device, the liquid spraying device, the road, etc., can solve the problems of affecting the smoothness of the asphalt pavement, the safety risk of the operators, and the unevenness of manual application, so as to reduce the manual work. , Strong adjustability, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

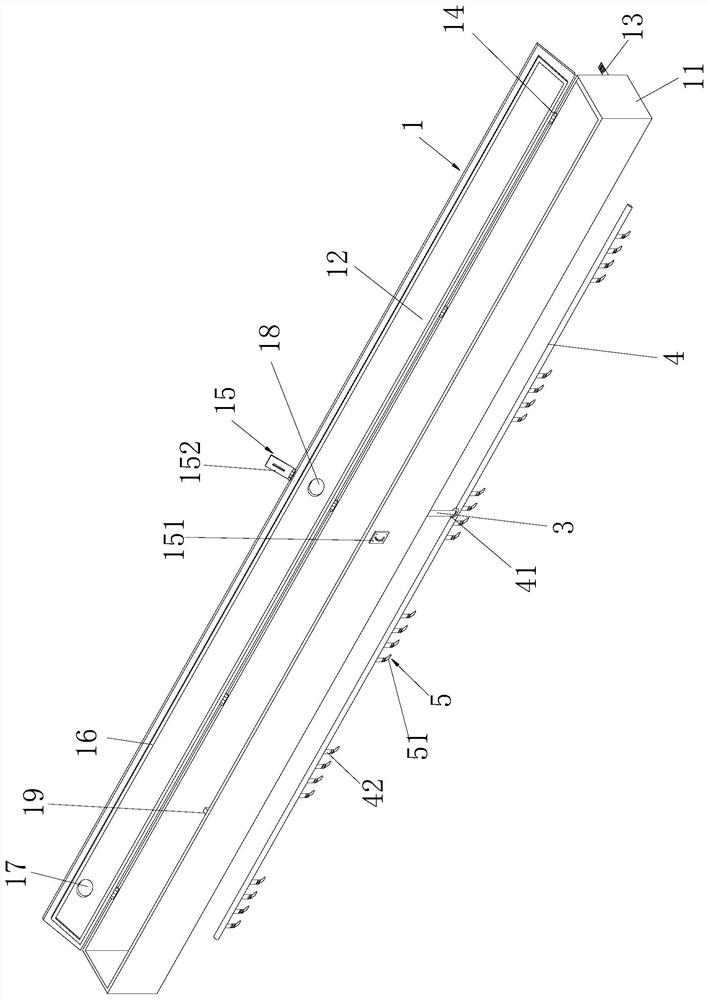

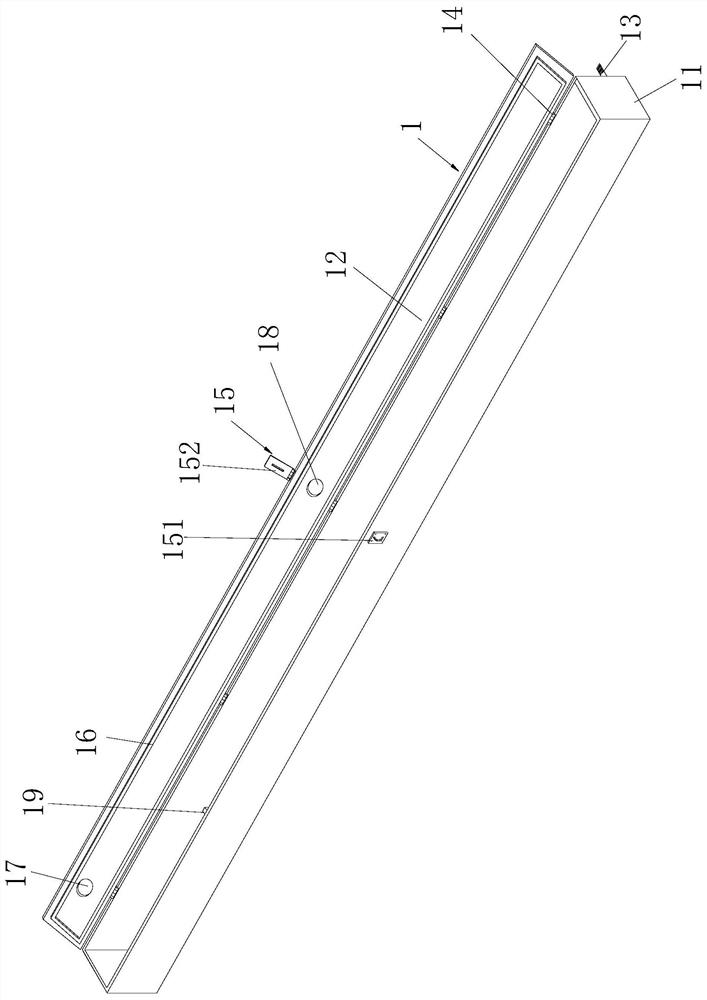

[0031] combine Figure 1 to Figure 4 , an oil-water spraying device for a rubber-tyred road roller, comprising a fuel tank 1 and a spraying mechanism. The fuel tank 1 includes a case shell 11 and a case cover 12 connected to the upper end of the case case 11. The roller body is connected.

[0032] The spraying mechanism includes a first spraying main oil pipe 2, the first spraying main oil pipe 2 communicates with the tank shell 11, the lower end of the first spraying main oil pipe 2 is connected with the third spraying horizontal pipe 4 through the second spraying vertical pipe 3, the third spraying There are multiple groups of nozzle mechanisms 5 connected to the horizontal pipe 4 , each group of nozzle mechanisms 5 includes a plurality of oil-water nozzles 51 , and the plurality of oil-water nozzles 51 are connected to the third spray horizontal pipe 4 in parallel.

[0033] The box shell 11 is a rectangular shell with an upper opening. One end of the box cover 12 is connec...

Embodiment 2

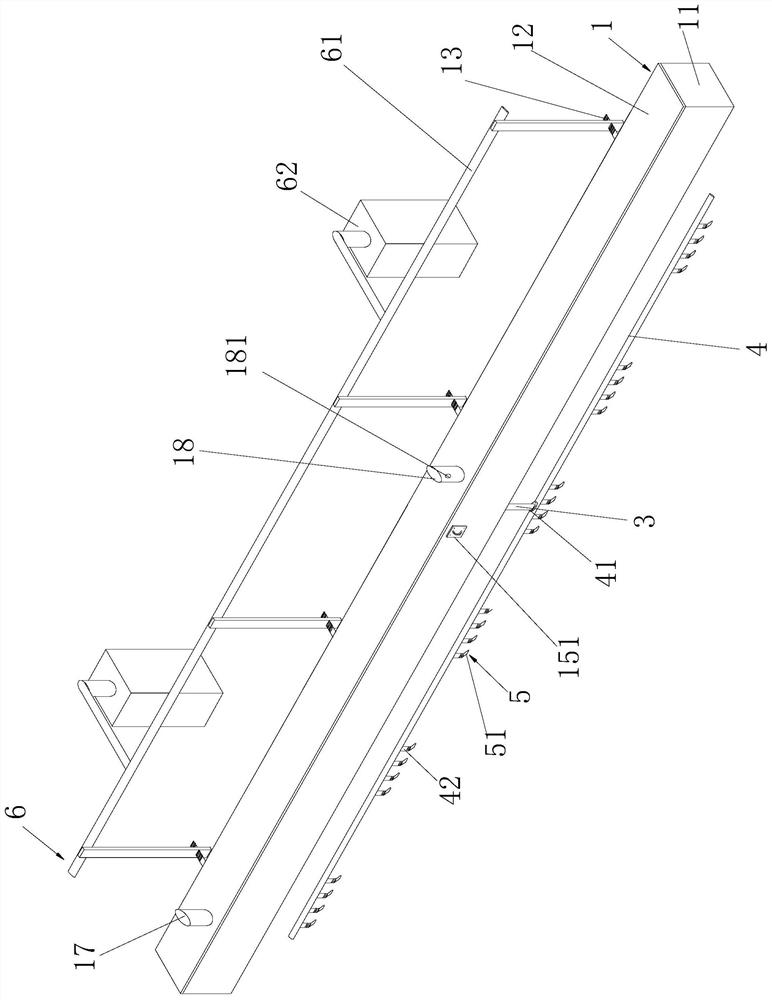

[0043] A rubber-tyred road roller, comprising the above-mentioned oil-water spraying device for the rubber-tyred road roller, a lifting mechanism 6 is arranged on the body of the rubber-tyred road roller, and the casing pole 13 in the oil-water spraying device for the rubber-tyred road roller is connected to the lifting mechanism 6 .

[0044]The lifting mechanism 6 includes a lifting bracket 61, a lifting electro-hydraulic cylinder 62 and a lifting controller. The lifting electro-hydraulic cylinder 62 is rotatably connected to the roller body through a hydraulic cylinder seat 63. The battery assembly inside is connected, and the lifting bracket 61 is connected on the cylinder shaft of the lifting electrohydraulic cylinder 62, and the lifting bracket 61 is fixedly connected with the box shell strut 13.

Embodiment 3

[0046] When the oil-water spraying device of the above-mentioned rubber-tyred road roller is in use, the oil-water spraying device of the rubber-tyred road roller is directly connected with the road roller body of the rubber-tyred road roller through the box shell strut 13 . Before use, the oil-water mixture is poured into the oil tank 1 through the oil filling pipe 17 . The oil-water mixture in the oil tank 1 enters into the third spray horizontal pipe 4 through the first spray main oil pipe 2 and the second spray vertical pipe 3, and the flow rate of the oil-water mixture is regulated by the flow regulating switch 32, which can reduce the oil flow rate by screwing in the flow regulating switch 32. The flow rate of the oil-liquid mixture can be increased by turning out the flow regulating switch 32. In the present invention, a plurality of groups of nozzle mechanisms 5 are arranged, and each group of nozzle mechanisms 5 sprays a group of rubber wheels in the rubber-tyred road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com