Nuclear safety level fuel transportation channel gate valve

A transportation channel and nuclear safety technology, applied in sliding valves, valve details, valve devices, etc., to achieve the effects of convenient operation and maintenance, lower overall height, and guaranteed strength and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

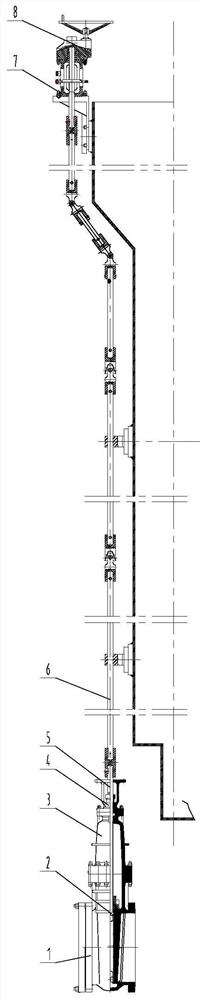

[0017] A nuclear safety grade fuel transport channel gate valve, the valve body, the valve cover and the upper valve cover are in the form of castings, the connection between the valve body and the valve cover is in the form of a middle flange connection, and the structure of the flexible graphite plate with stainless steel wire is adopted. It ensures high reliability and safety of the valve. The connection between the bonnet and the upper bonnet is in the form of flange connection, and adopts the structure of winding controllable compression gasket, which ensures the high reliability and safety of the valve. The structure of the dark rod wedge gate valve is adopted, the overall height of the valve is reduced, the structure is compact, and the strength and seismic performance of the valve are increased by means of reinforcement. The ultra-long remote transmission mechanism with rigid shaft connection is designed to ensure strength and efficiency. At the same time, the corresp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap