Environment-friendly garbage treatment device

A waste treatment device and an environmentally friendly technology, which is applied in the fields of waste drying, dry goods processing, biomass post-processing, etc., can solve the problems of wasting resources, polluting the environment, destroying social harmony, etc., and achieves high usability and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

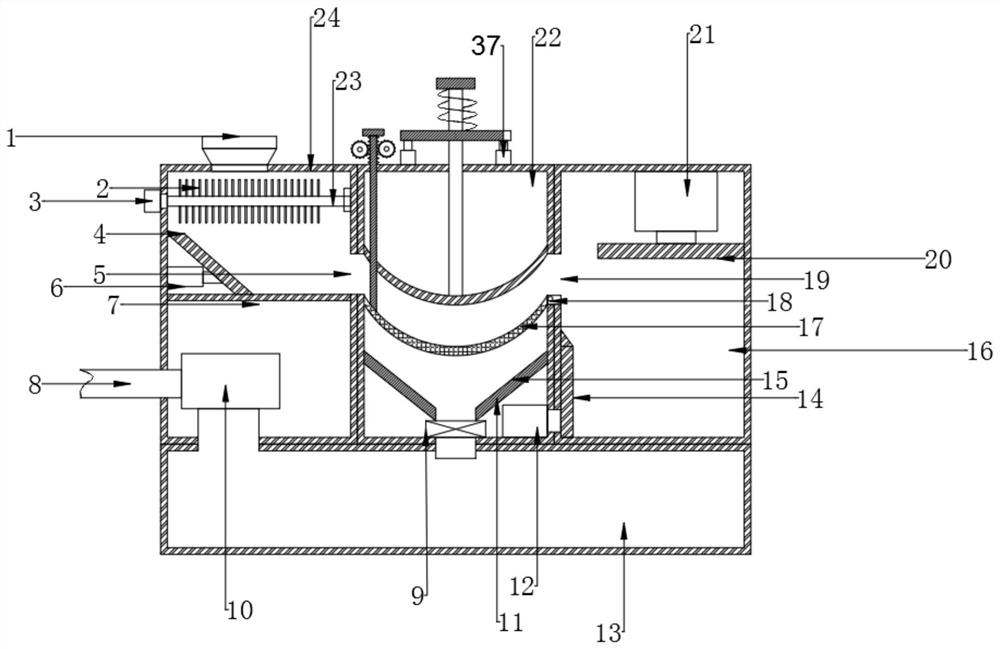

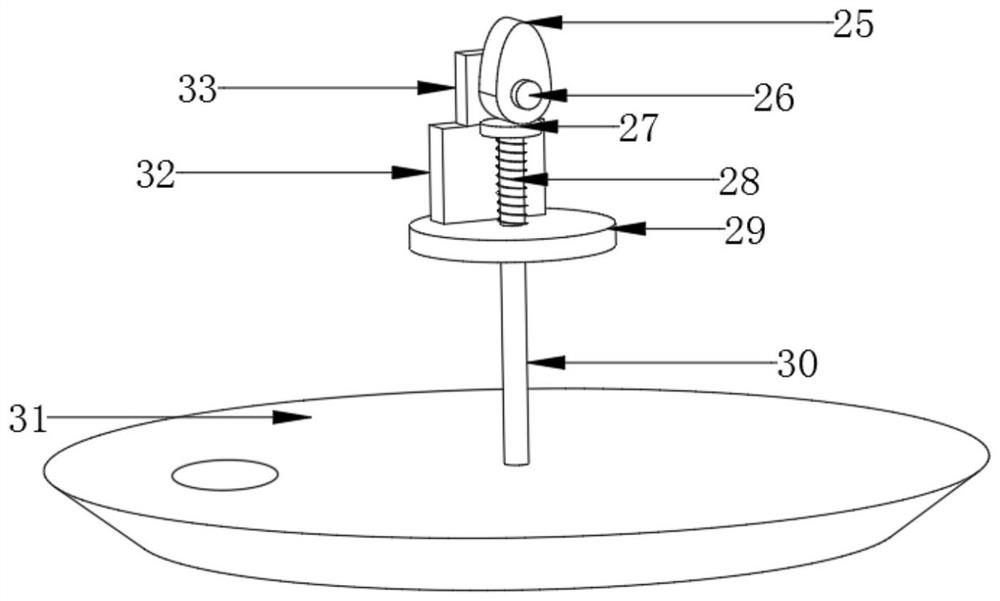

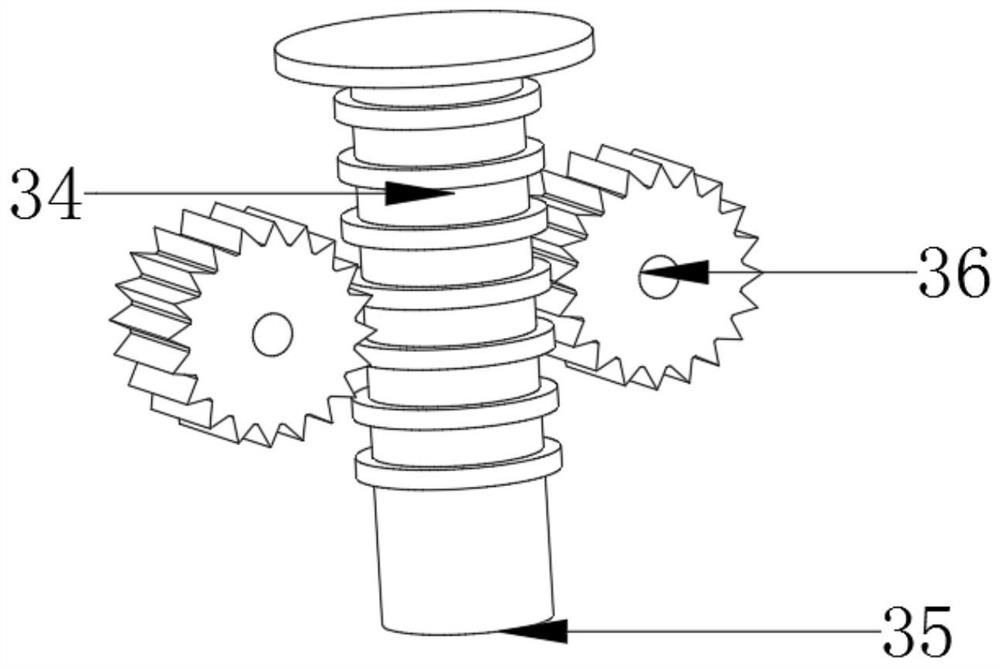

[0023] see Figure 1~4 , in the embodiment of the present invention, an environment-friendly garbage treatment device, including an inlet 1, a crushing box 24, a solid-liquid separation box 22, a solid collection box 16, and a liquid biogas box 13, and the middle position above the liquid biogas box 13 is set There is a solid-liquid separation box 22, a smashing box 24 is arranged on the left side above the liquid biogas box 13, a solid collection box 16 is arranged on the right side of the liquid biogas box 13, and the entrance 1 is arranged on the top of the smashing box 24, The crushing box 24 includes a crushing structure, a pushing structure, a primary outlet 5 and a partition 7, the crushing structure is arranged below the inlet 1, and the partition 7 is arranged in the middle of the crushing box 24 position, the pushing structure is arranged above the partition 7, the primary outlet 5 is arranged on the side of the partition 7, and the solid-liquid separation box 22 inc...

Embodiment 2

[0030] Compared with Embodiment 1, the improvement of this embodiment lies in that a gas extraction structure 10 is provided on the side of the liquid biogas tank 13 , and a gas output pipe 8 is provided at the output end of the gas extraction structure 10 . The gas generated by the biogas can be sampled and detected through the gas extraction structure 10 .

[0031] Example 2

[0032] The working principle of the present invention is as follows: first pour the garbage from the entrance 1, the smashing motor 3 drives the smashing shaft 23, and smashes it with the smashing teeth 2, and then pushes the inclined push plate 4 through the smashing telescopic rod 6 to make the garbage Enter the screen 17 through the primary outlet 5, and then adjust the top hydraulic cylinder 37, so that the extrusion platform 31 is squeezed downward on the screen 17, and the motor 33 drives the rotating shaft 26, and then drives the crank 25, so that the moving rod 30 moves up and down Move, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com