Automobile steering wheel vibration reduction structure

A vibration-damping structure and steering wheel technology, which is applied to steering control, vehicle components, springs/shock absorbers installed on the car, etc., can solve the problem of the small space inside the steering wheel, it is difficult to suppress low-frequency small-amplitude vibration, and the structural arrangement is difficult, etc. It can improve the driving experience and comfort, facilitate the platform layout of products, and achieve the effect of good vibration reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

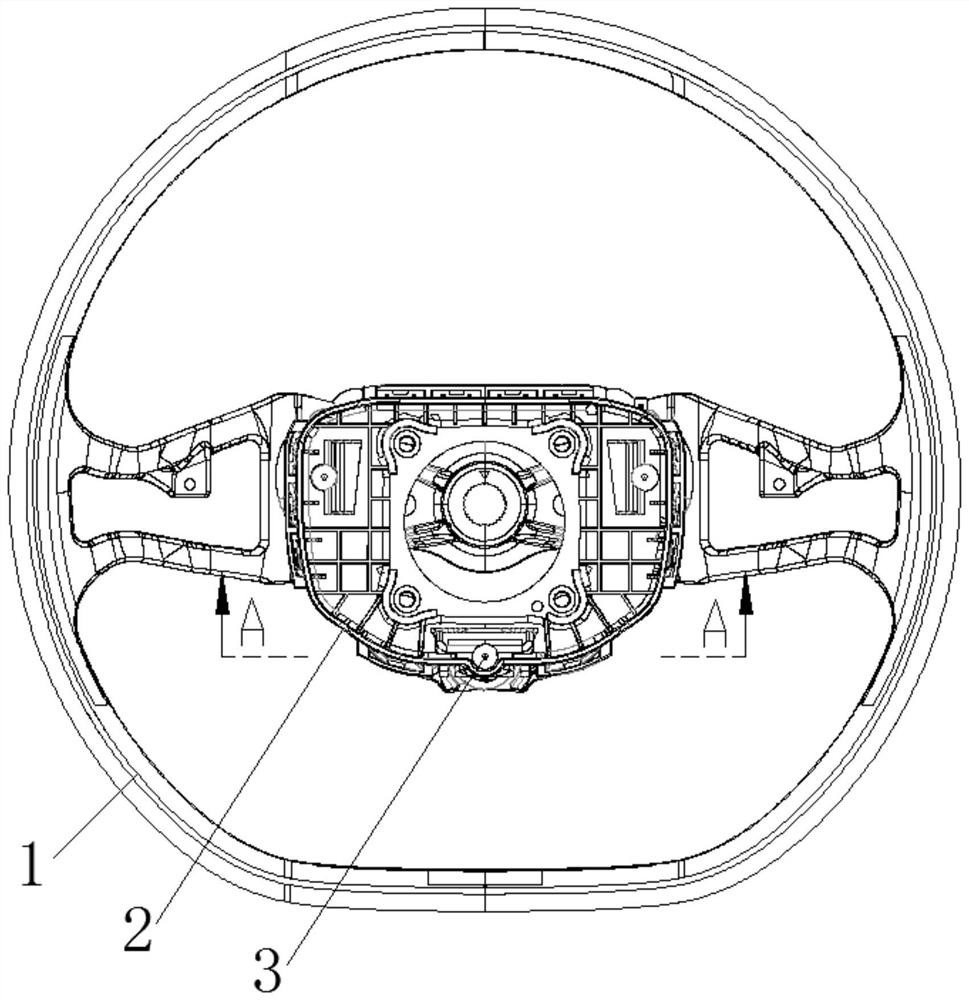

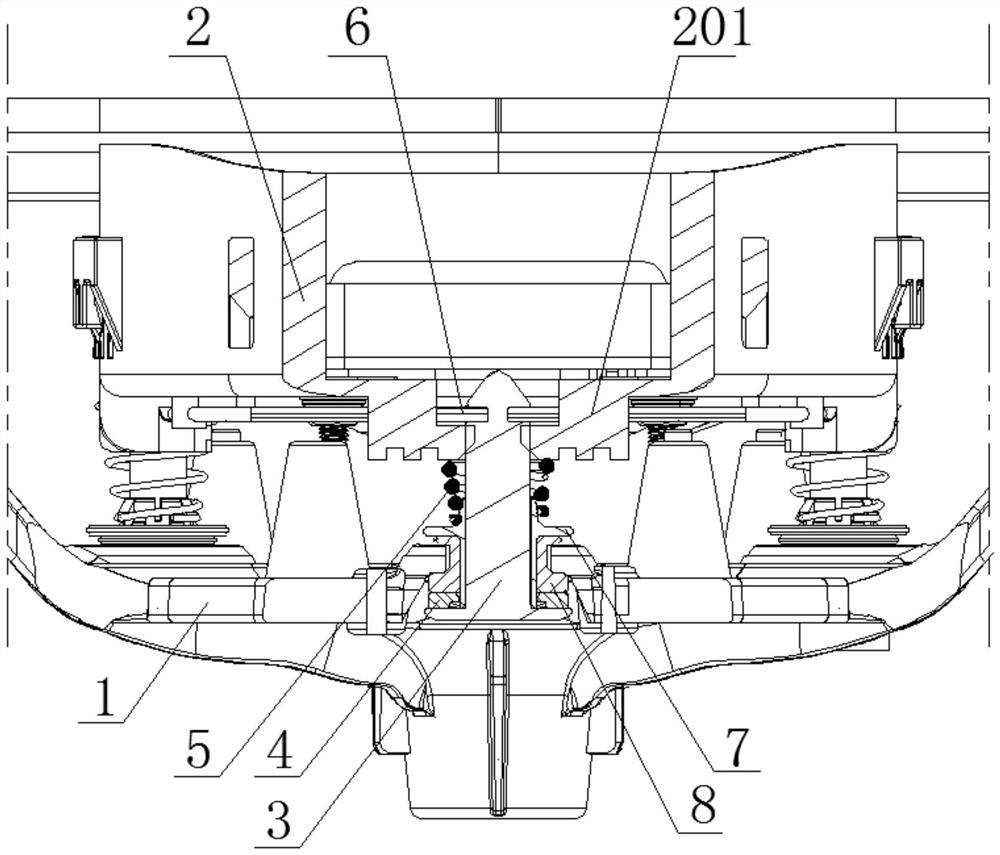

[0032] Such as Figure 1-Figure 4 As shown, a kind of automobile steering wheel vibration damping structure related to the present invention includes a metal frame 1 and an air bag module, and at least two vibration damping units are arranged on the metal frame 1, and connecting pins 3 are respectively inserted in each vibration damping unit. The upper end of the connecting pin 3 is connected to the supporting plate 2 of the airbag module, and is used to use the airbag module as a counterweight to absorb energy and reduce vibration through the damping unit.

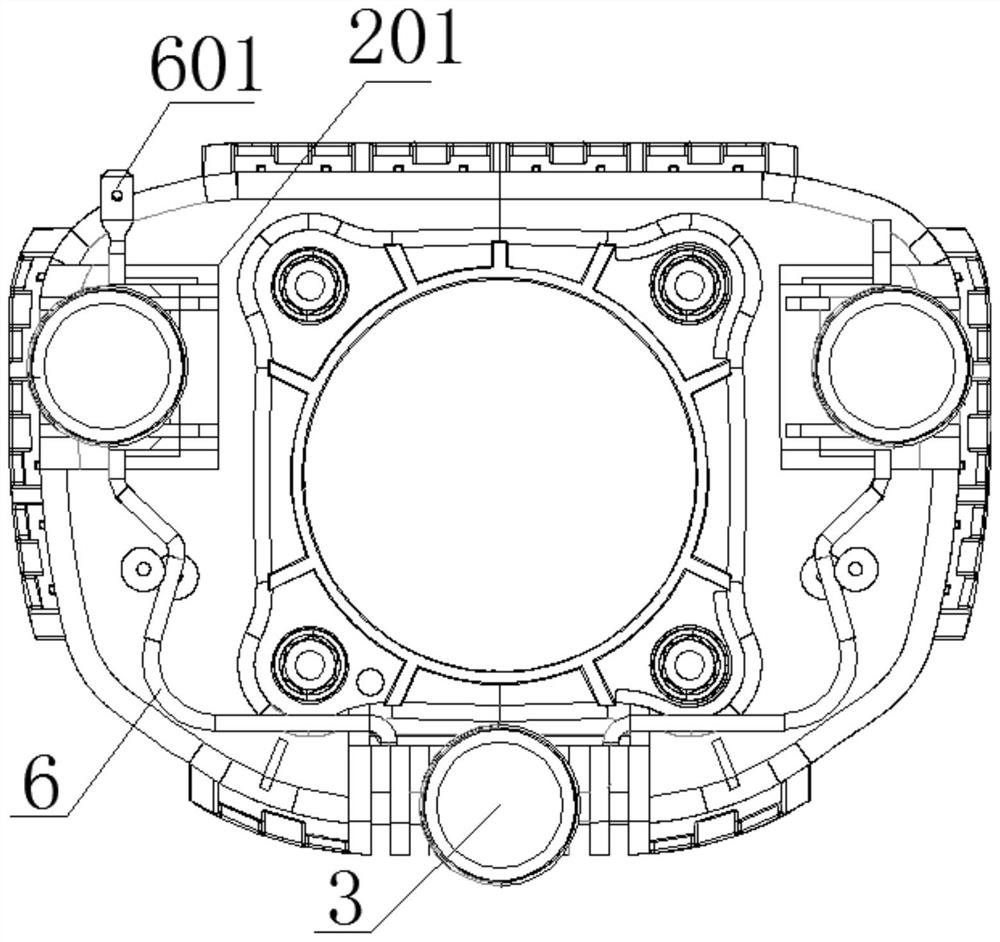

[0033] Preferably, there are three damping units, which are arranged on the metal frame 1 in an isosceles triangle shape.

[0034] The damping unit includes a damping sleeve 8, a buckle 7 and a damping spring 5, the buckle 7 is set on the connecting pin 3 and embedded in the damping sleeve 8, and the damping sleeve 8 is embedded in the buckle Installed in the corresponding installation hole on the metal frame 1, the damp...

Embodiment 2

[0042] Such as Figure 1-Figure 4 with Figure 7As shown, a kind of automobile steering wheel vibration damping structure related to the present invention includes a metal frame 1 and an airbag module, and at least two vibration damping units are arranged on the metal frame 1, and connecting pins 3 are respectively inserted in each vibration damping unit. The upper end of the connecting pin 3 is clamped to the airbag module through the torsion spring 6, and is used to use the airbag module as a counterweight to absorb energy and reduce vibration through the vibration damping unit.

[0043] One end of the torsion spring 6 is provided with a plug-in piece 601, and the input signal of the vehicle horn is connected through the plug-in piece 601; on the metal frame 1, near each vibration-damping unit, there is a conical boss under the corresponding torsion spring 6 101, and rivets 12 are respectively provided on the upper end of the boss 101 to form a horn mechanism, and the torsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com