Environment-friendly waste device with cleaning and compaction functions

A garbage and environmental protection technology, applied in garbage bins, garbage collection, garbage cleaning, etc., can solve the problems of small garbage storage, large occupied area, and heavy workload, and achieve the advantages of convenient operation, good applicability, and improved work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

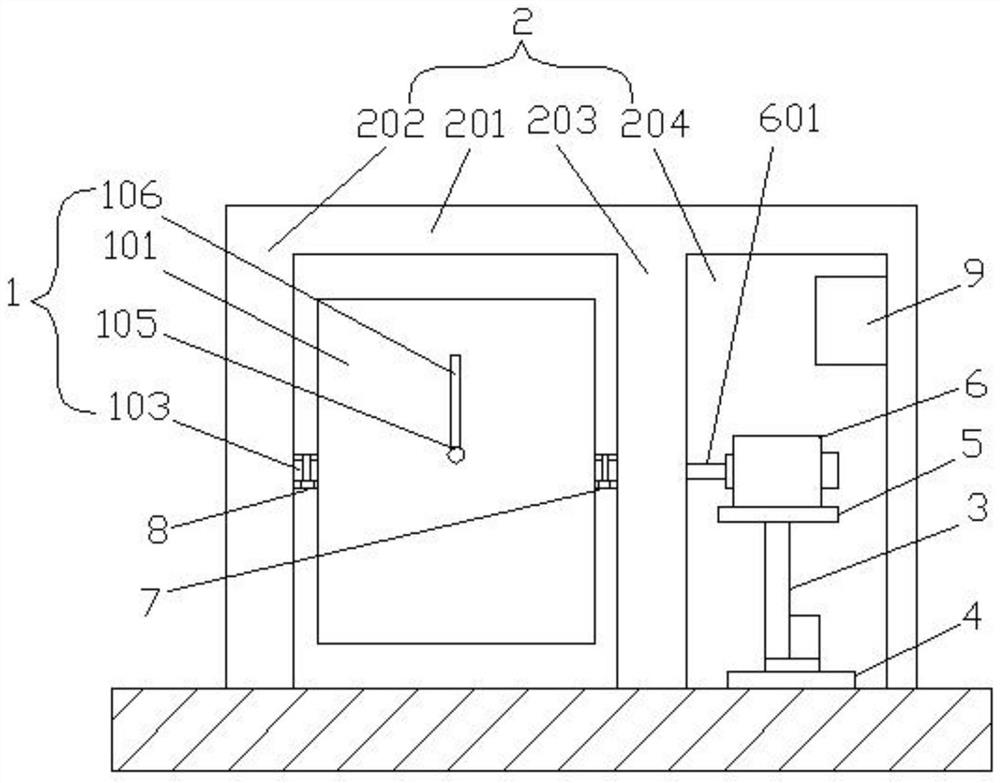

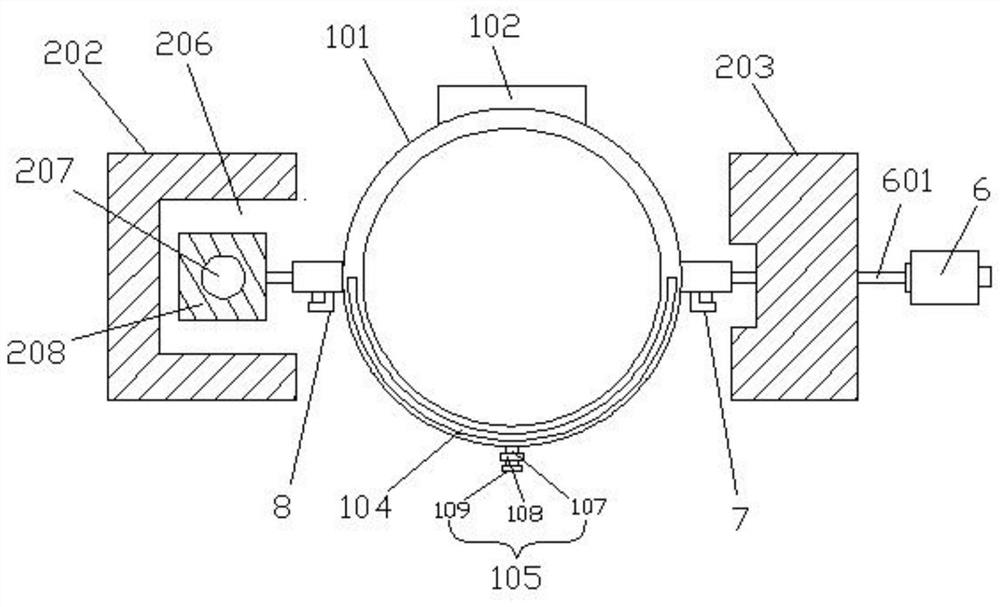

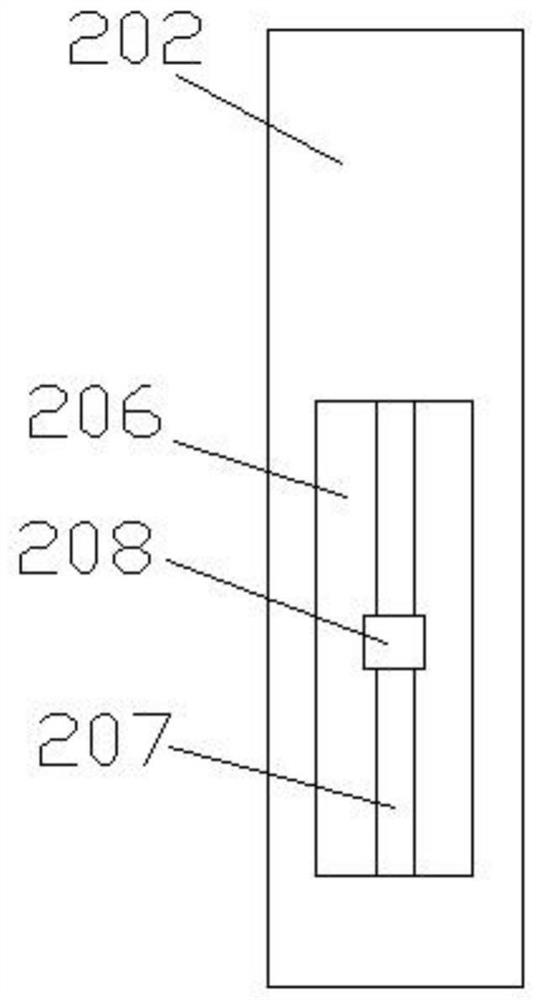

[0035] as shown in the picture Figure 1 to Figure 6 As shown, the above-mentioned garbage can 1 includes a cylindrical barrel body 101, a garbage input port 102 located at the rear of the barrel body 101, and a square protrusion 103 extending outward from the vertical middle position on both sides of the barrel body 101, and is installed in the barrel. The conveying arc plate 104 on the body 101, further, the above-mentioned conveying arc plate 104 is inserted into the barrel body 101 on the top wall of the front part of the barrel body 101, and a handle 105 is fixedly connected to the center line of the convex surface of the conveying arc plate 104, and the handle 105 passes through The bar groove 106 provided on the barrel body 101 extends to the front of the barrel body 101, and the handle 105 includes a screw rod 107 connected to the conveying arc plate 104, a locking block 108 sleeved on the screw rod 107, and a limiter located at the outer end of the screw rod 107. The ...

Embodiment 2

[0041] combine Figure 7-Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that it has the function of compacting the garbage stored in the garbage can 1 and cleaning the garbage can 1 after the garbage is poured out. In order to achieve the above-mentioned purpose, This embodiment is realized by adding the following structures: a vertically inverted second electric telescopic rod 10 is arranged at the bottom of the above-mentioned protective cover 201, a second drive motor 11 installed on the telescopic end of the second electric telescopic rod 10, a second drive motor 11 installed on the second electric telescopic rod 10 2. The disc-shaped brush body 12 at the power output end of the drive motor 11, specifically, the disc-shaped brush body 12 is positioned above the barrel mouth of the barrel body 101, and the diameter of the disc-shaped brush body 12 is matched with the size of the barrel mouth so that it can match the barrel body. The inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com