Brake disc loading and unloading clamp capable of automatically changing spacing

A variable pitch and brake disc technology, applied in the field of brake disc loading and unloading fixtures, can solve problems such as low production efficiency, potential safety hazards, and increased automation needs, and achieve the effects of improving grasping efficiency, ensuring product quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

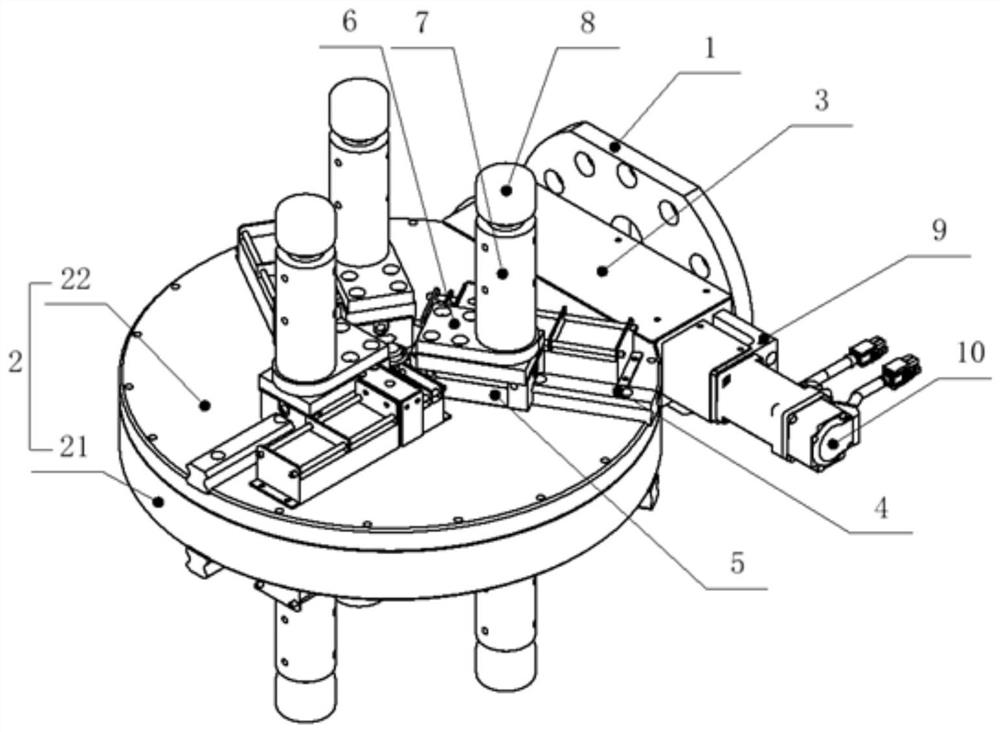

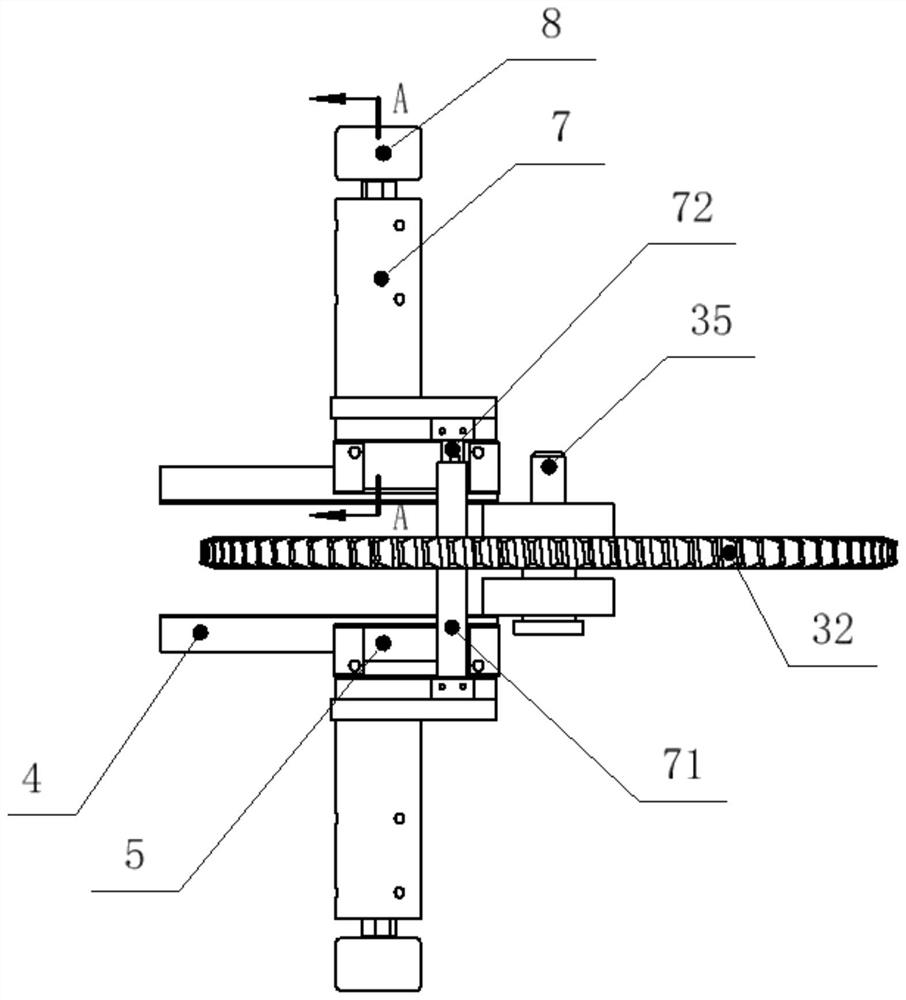

[0019] An automatic variable pitch brake disc loading and unloading fixture, comprising a frame body 2, a transmission device 3 that is movably connected inside the frame body 2, and the transmission device 3 is provided with at least three drive claws 7 that are movably connected, and the drive claw 7 is connected to the frame The body 2 is movably connected, and the free end of the driving claw 7 is provided with an electromagnet 8 .

[0020] The frame body 2 includes a fixed frame 21, and fixedly connected fixed plates 22 are arranged on the upper and lower sides of the fixed frame 21.

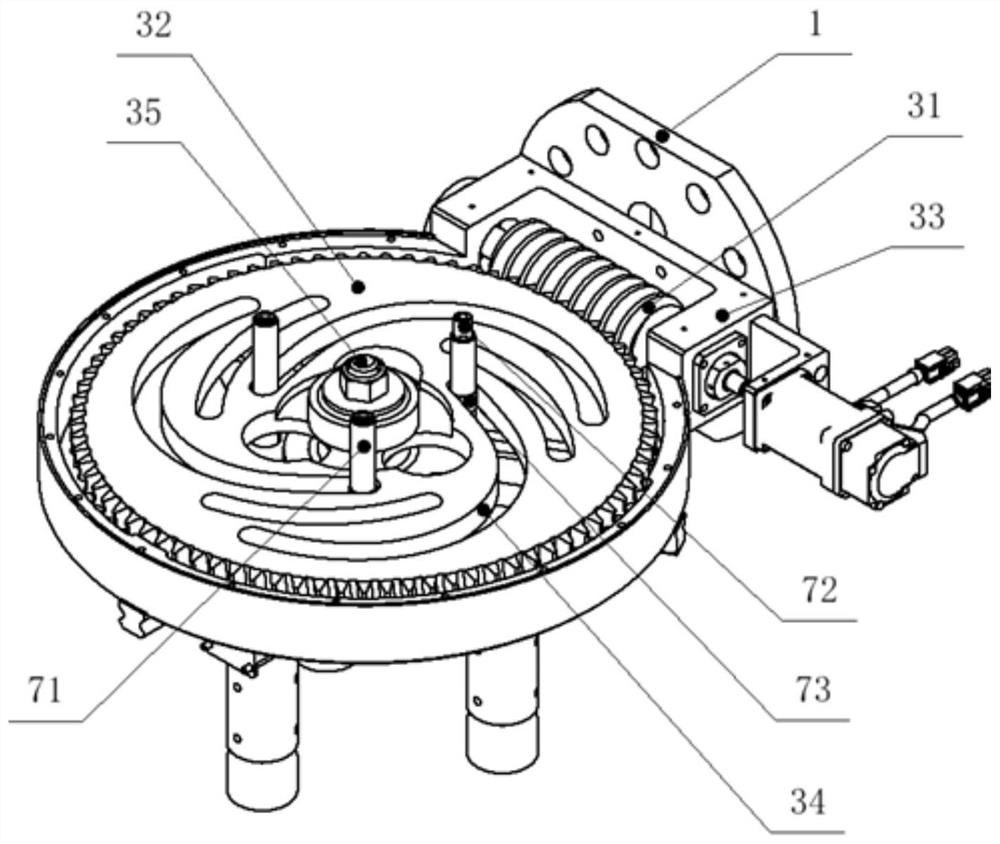

[0021] The transmission device 3 includes a worm wheel 32 installed in the frame body 2, the worm wheel 32 is movably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com