Flatness measuring device and using method thereof

A measuring device and flatness technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficulty in measuring the flatness of the structure to be measured, and achieve the effects of simple structure, reduction of high-altitude operations, and safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

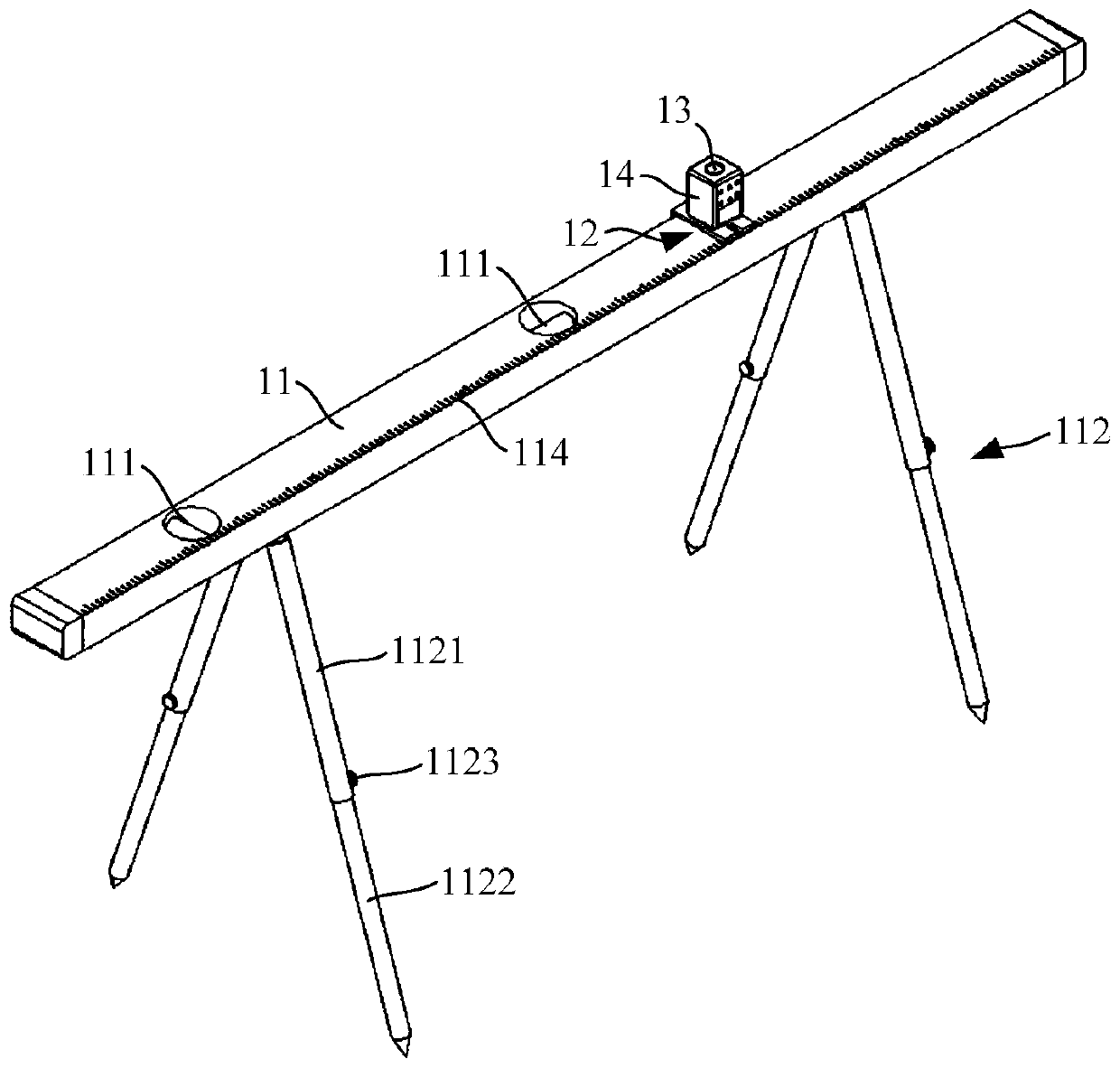

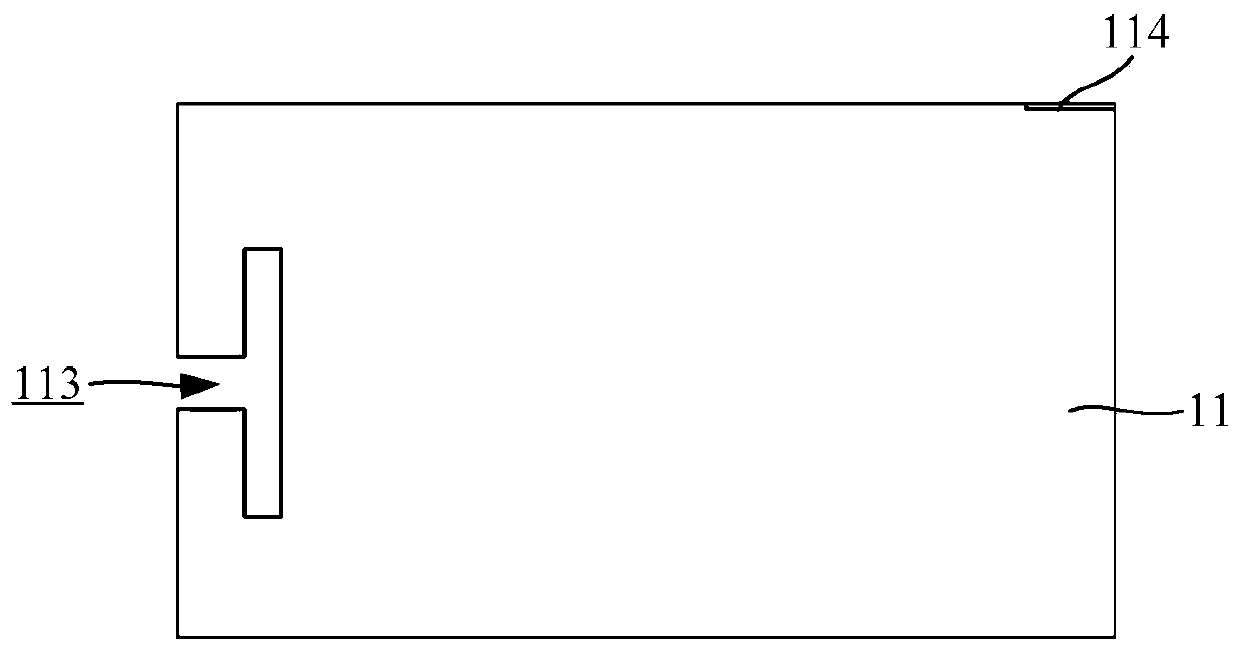

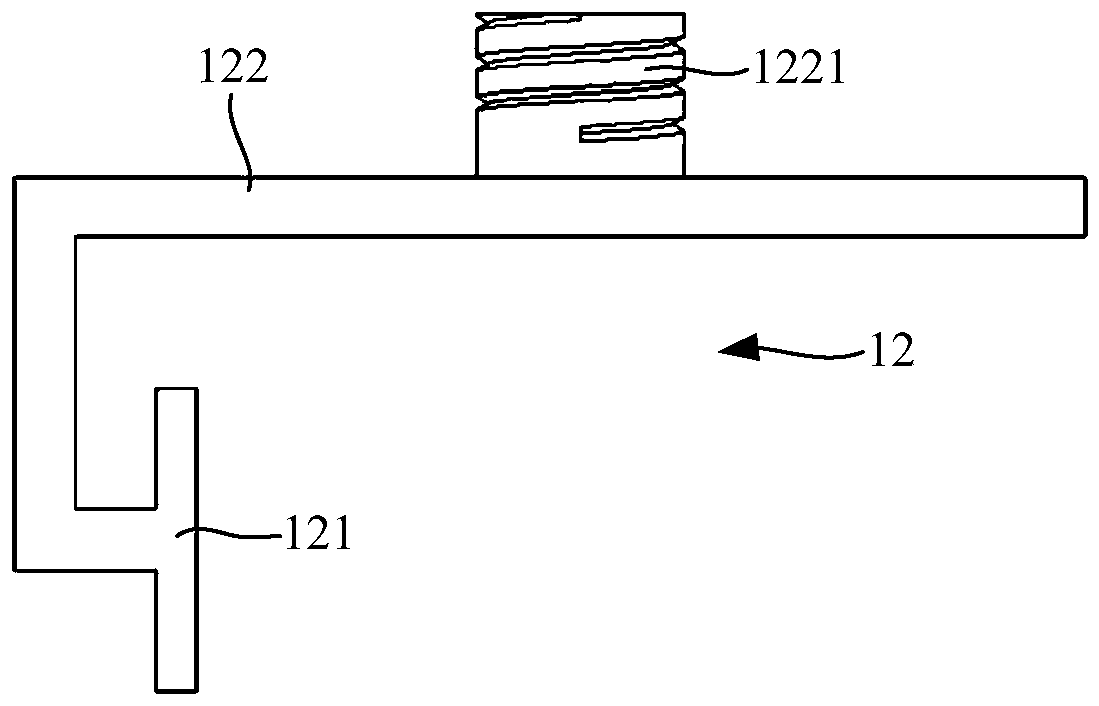

[0035] refer to figure 1 , the present invention provides a flatness measuring device and its use method. The main ruler is adjusted to the level through the leveling bubble and the adjusting member. The structure to be measured can be used to reduce the high-altitude operations of the surveyors. After the main ruler is leveled, the laser range finder can be used to directly emit laser light to the structure to be measured, and the laser range finder can be moved along the main ruler to obtain several groups of main ruler and the target structure. The distance between the measured structures, and the flatness of the structure to be measured can be obtained after comparison, which solves the problem of difficulty in measuring the flatness of the structure to be measured, can ensure measurement accuracy, and ensure construction quality. In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com