Drilling machine assembly with drilling pipe righting function

A drill pipe and functional technology, which is applied in the field of drilling rig assembly with drill pipe straightening function, can solve problems such as threatening the personal safety of workers, drill pipe detachment in the hole, arm fractures, etc., to ensure personal safety, eliminate safety hazards, Eliminate the effect of lost diamonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

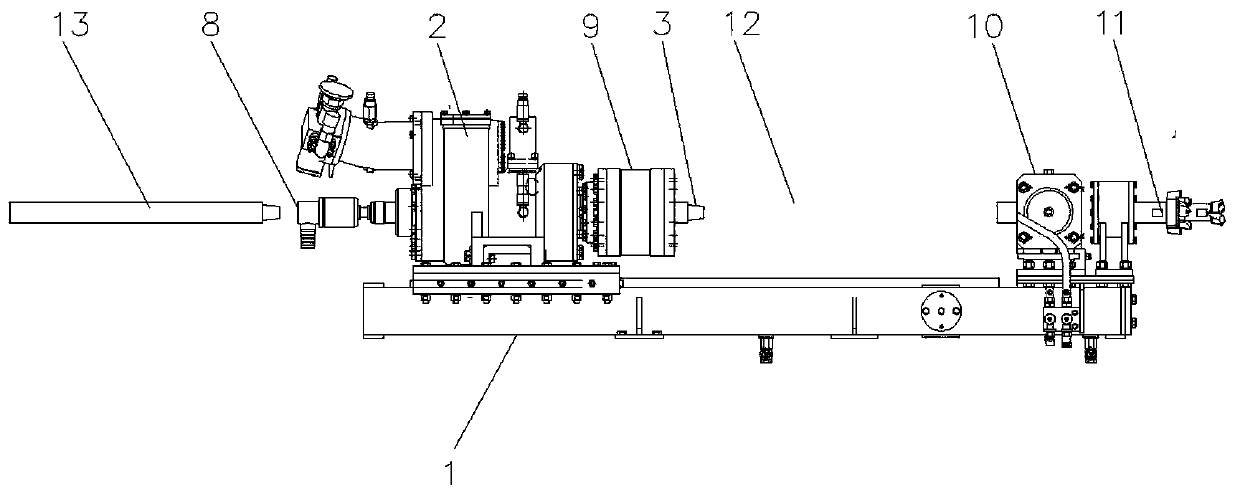

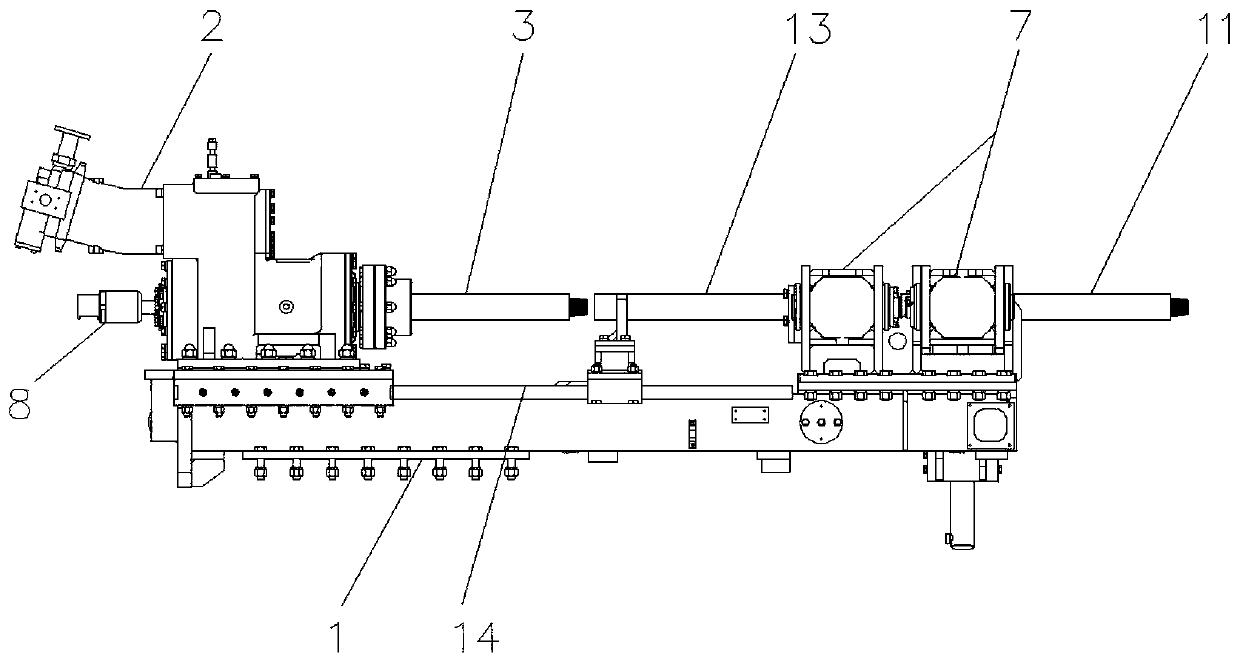

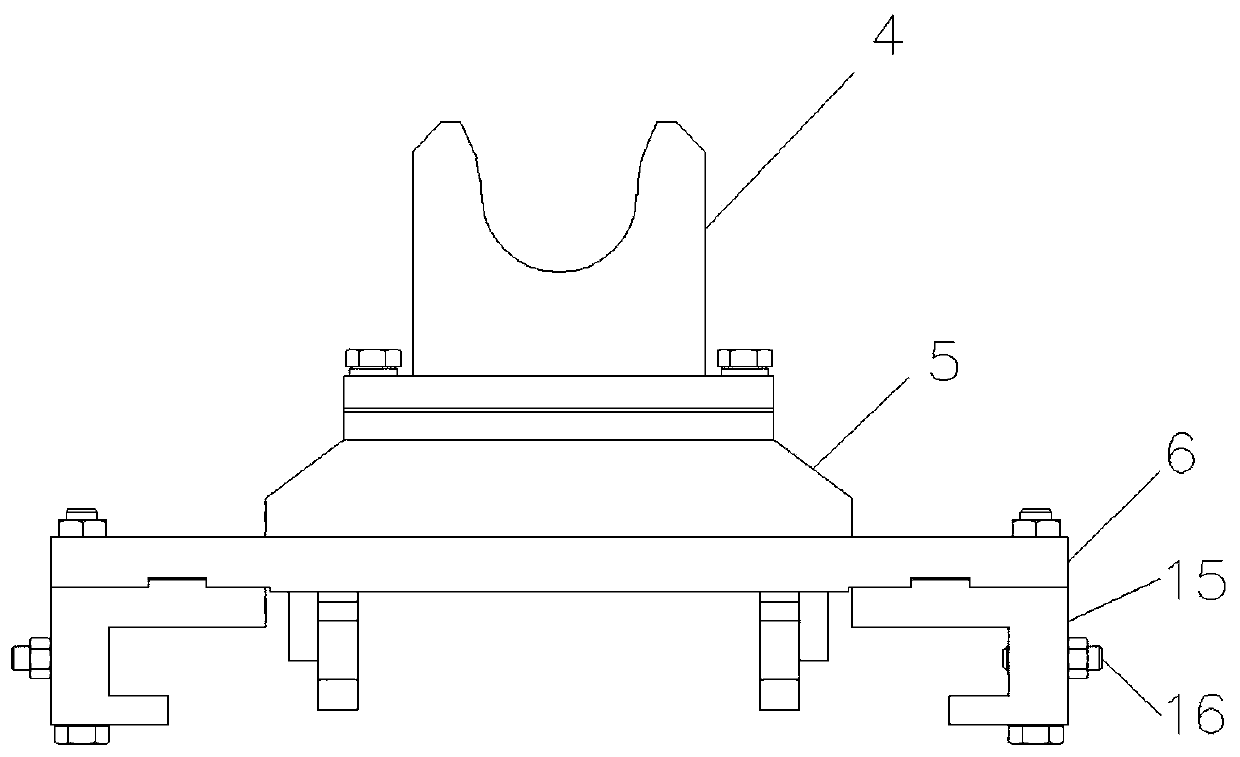

[0020] figure 1 Schematic for the existing structure figure 1 ; figure 2 Is a schematic diagram of the three-dimensional structure of the present invention; image 3 Schematic diagram of the structure of the centralizing device; Figure 4 Schematic diagram of the holder structure;

[0021] The forward and backward directions in this embodiment are figure 1 with figure 2 The axial direction of the middle drill rod;

[0022] Such as figure 1 As shown, the existing drilling rig includes a frame 1, on which a power assembly 2 can be slid back and forth. The front side transmission of the power assembly drive is matched with a chuck I9, and a chuck II 10 is provided on the front side of the chuck I. The chuck II is fixedly connected to the frame, and a water braid 8 is connected to the rear side of the power assembly. An active drill rod 3 is provided in the power assembly and driven to rotate by the power assembly, and the active drill rod is stuck in the chuck Ⅰ9;

[0023] The struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com