Automatic roll changing and splicing system and method for disposable sanitary product production equipment

A technology for sanitary products and production equipment, which is applied in the field of automatic coil changing and splicing systems, can solve the problems that production costs cannot be effectively controlled, production costs cannot be effectively controlled, and automatic operations are not realized, and the loss of raw materials is reduced, and labor costs are low. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

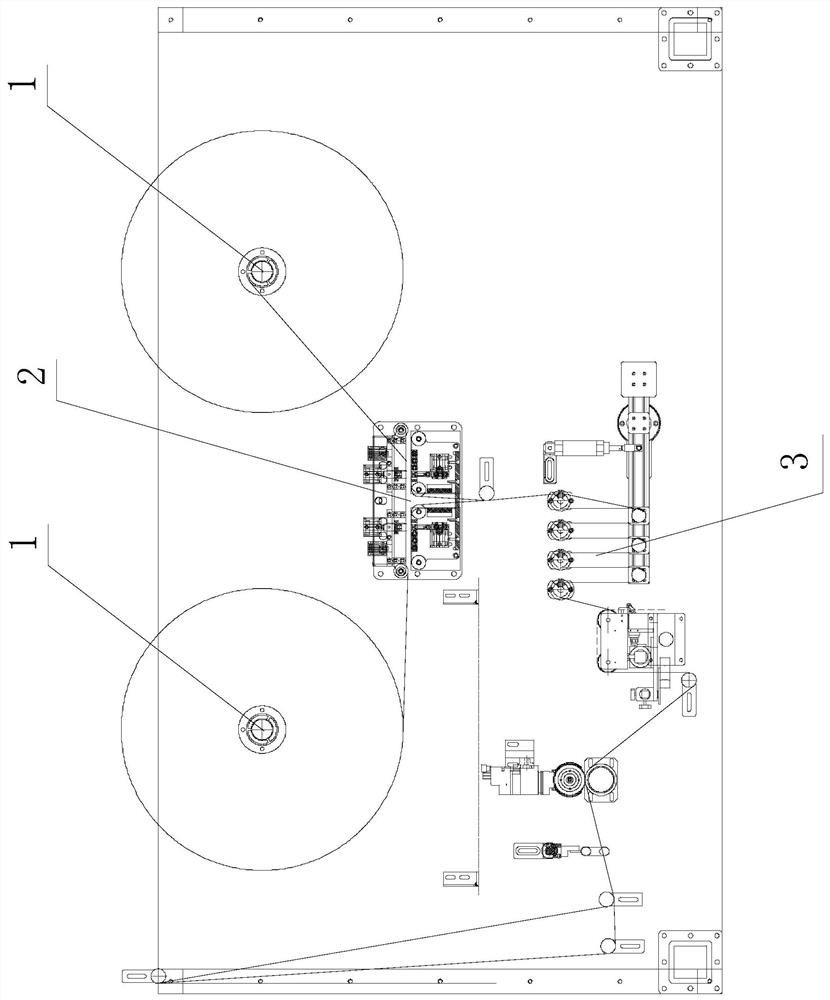

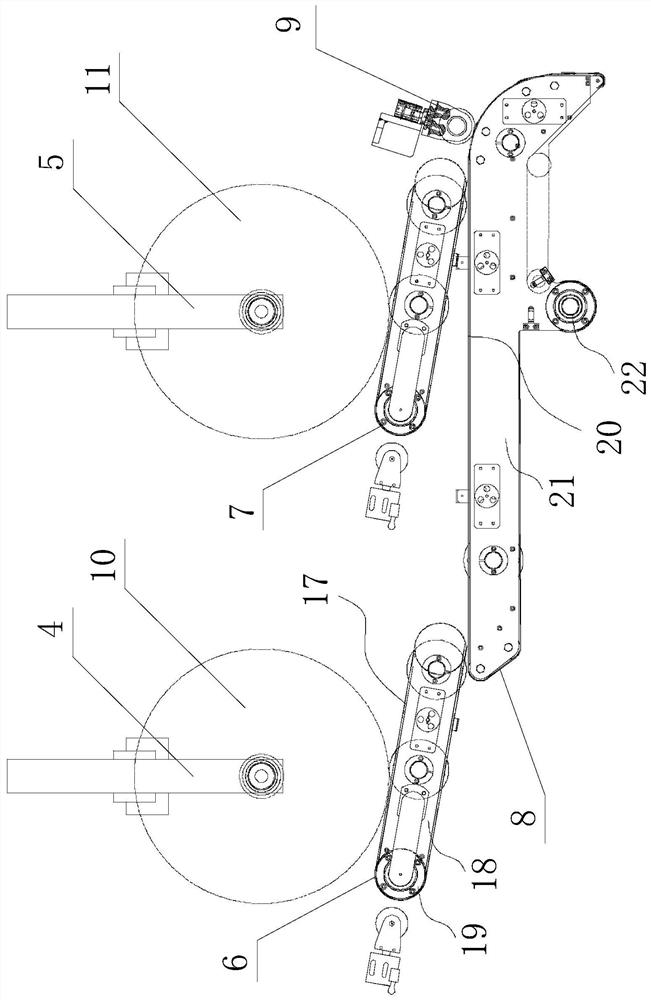

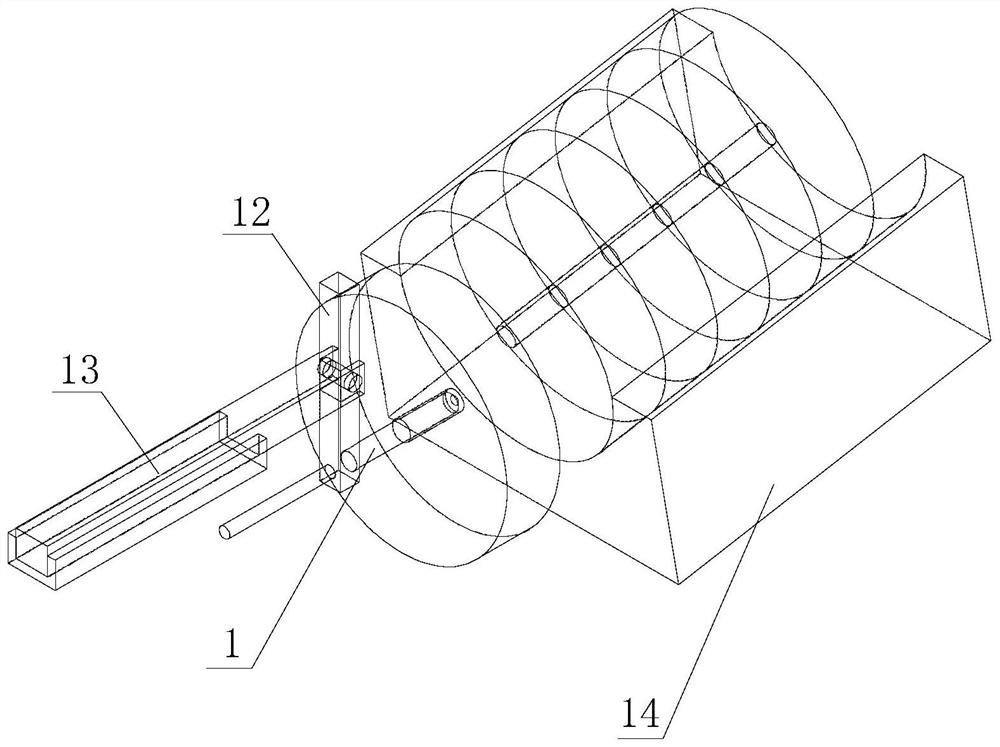

[0032] A kind of automatic roll-changing material-receiving system used for the production equipment of disposable hygiene products in this embodiment, such as figure 2 As shown, it includes a first unwinding mechanism 4, a second unwinding mechanism 5, a first unwinding negative pressure conveying device 6, a second unwinding negative pressure conveying device 7, a main negative pressure conveying device 8 and an ultrasonic pressing device 9 , the first unwinding mechanism is provided with a first coil 10, after the first coil is released, it is transported by the first unwinding negative pressure conveying device and sent to the main negative pressure conveying device, and the second unwinding mechanism is provided with The second coil 11, after the second coil is released, it is conveyed by the second unwinding negative pressure conveying device and sent to the main negative pressure conveying device; the ultrasonic pressing device is arranged on the side of the main negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com