Bridge floor crane

A technology of cranes and hanging baskets, which is applied in the direction of walking bridge cranes, bridges, cranes, etc., which can solve the problems of lack of free adjustment in the longitudinal direction, complex structure, high processing cost, etc., to avoid low dimensional accuracy requirements, The effect of simplifying the processing technology and avoiding the cost of the truss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

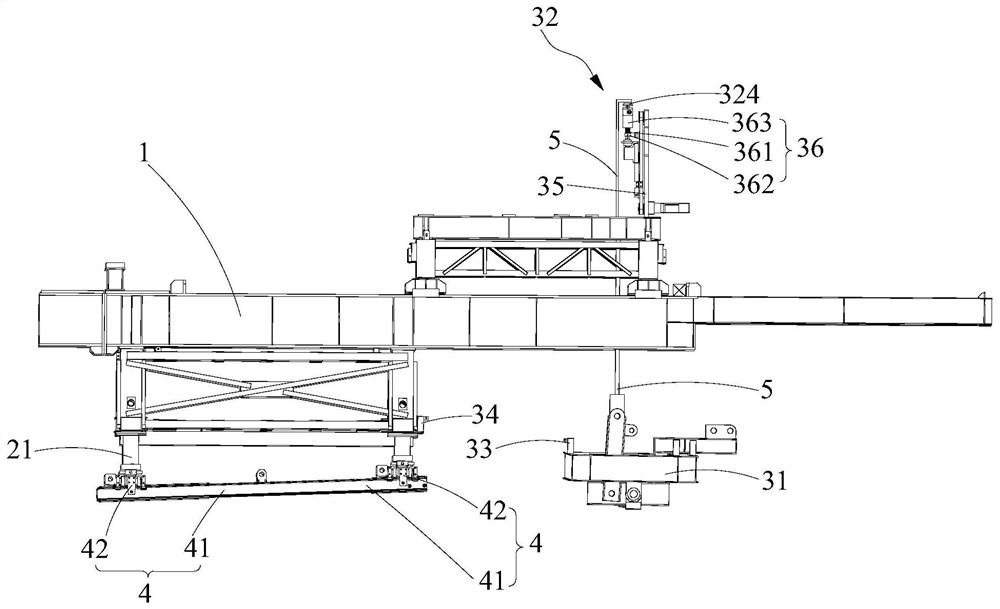

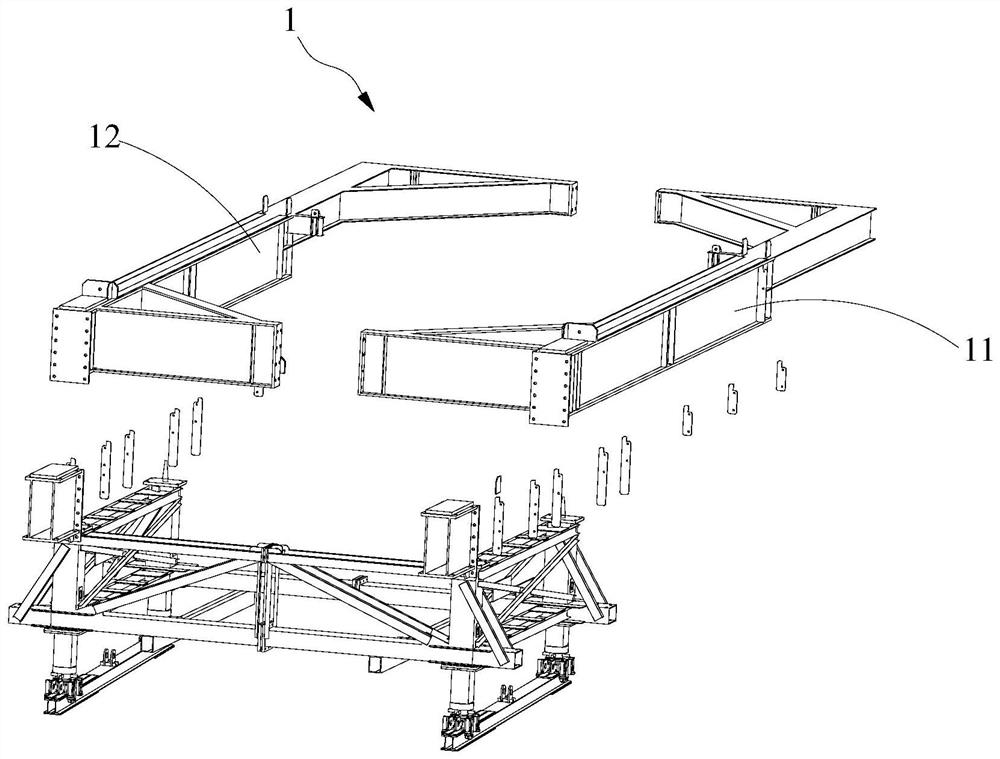

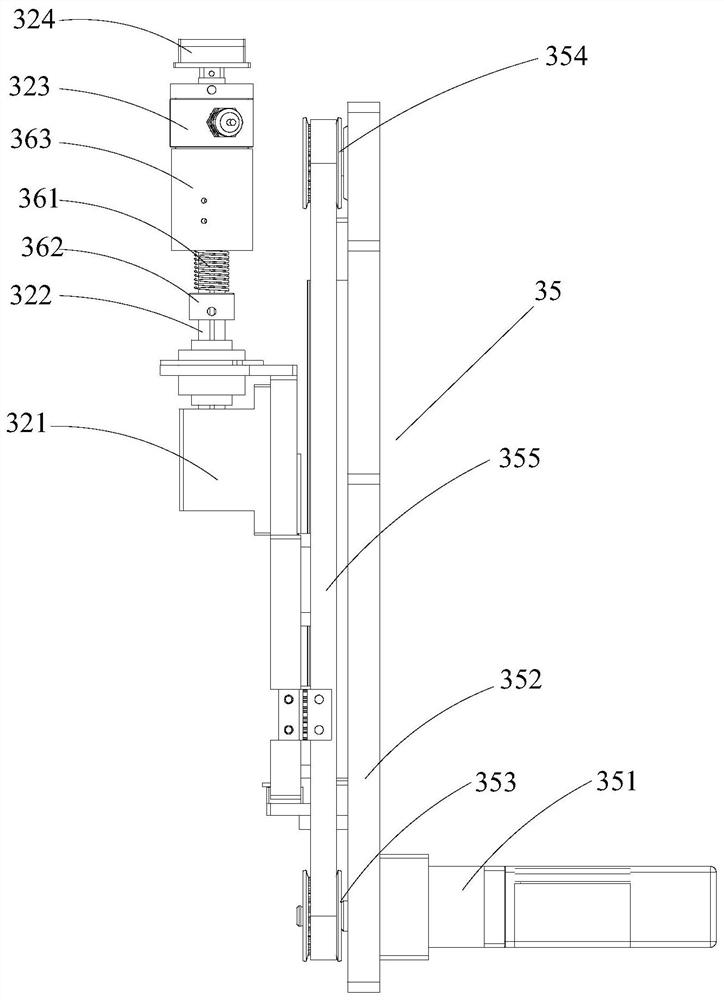

[0029] Further, see figure 1 and image 3 , as a specific embodiment of the bridge deck crane provided by the present invention, the lifting mechanism 3 includes a hanging basket 31 and a lifting assembly 32. The lifting assembly 32 is arranged on the load-bearing truss 1 and can drive the hanging basket 31 to lift. The hanging basket 31 is provided with a first sensing device 33, and the support column 21 is provided with a second sensing device 34. The first sensing device 33 can cooperate with the second sensing device 34 to monitor whether the hanging basket 31 has reached a preset height. . In this way, when the hanging basket 31 rises under the driving of the lifting assembly 32, and when the hanging basket 31 rises to a preset height, the second sensing device 34 and the first sensing device 33 sense each other to send a signal, and the lifting assembly 32 stops driving. The hanging basket 31 rises, which improves the splicing efficiency and shortens the construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com