Preparation process of assembled wall

A preparation process and assembly technology, which is applied to walls, building components, buildings, etc., can solve the problems that automatic production cannot be realized, the feeding speed cannot match the production speed well, and the assembly wall cannot be produced efficiently and quickly. , to avoid insufficient keel supply, save manpower and production costs, and improve production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the application clearer, the embodiments of the application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

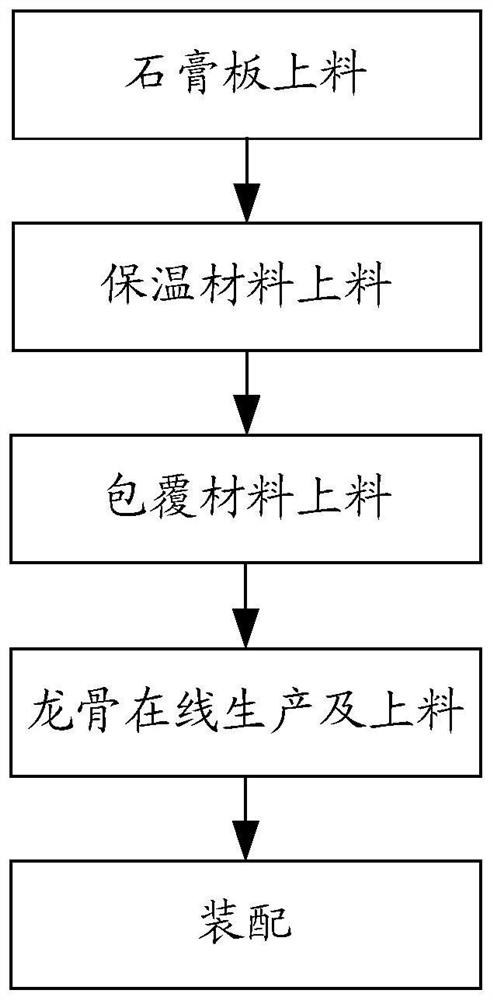

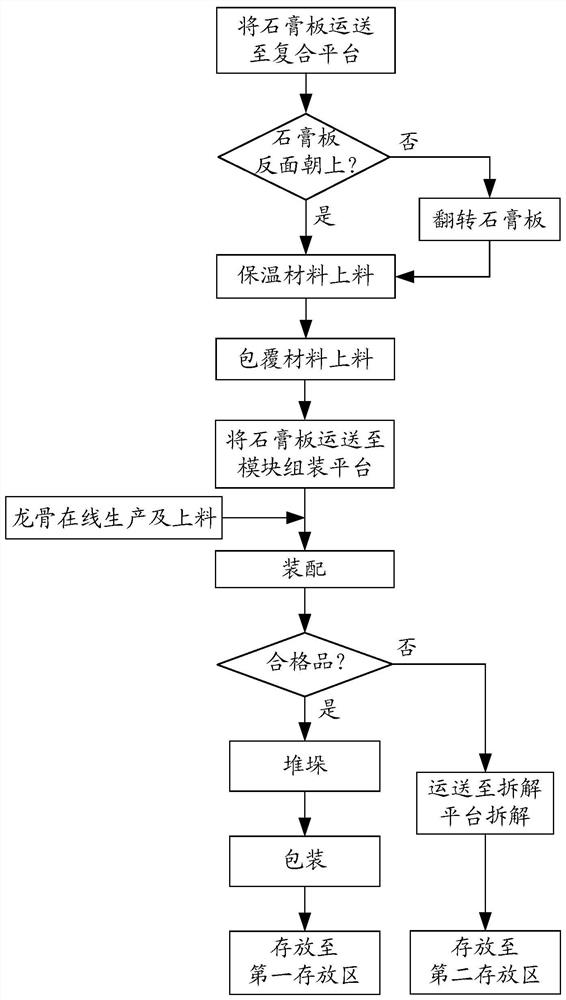

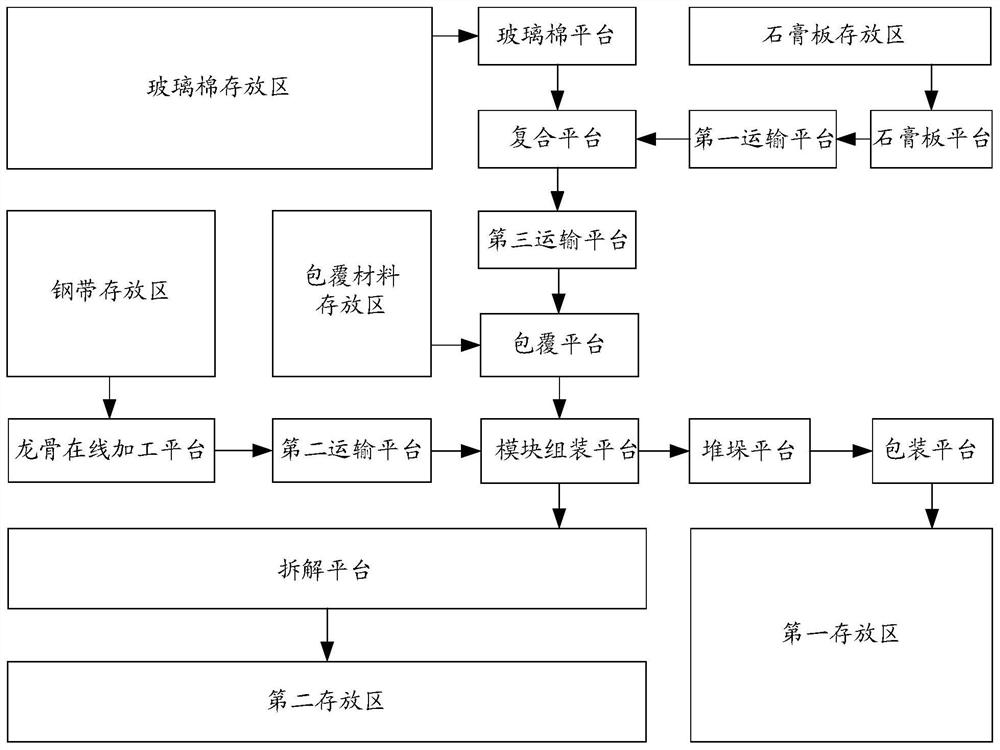

[0020] The application provides a preparation process for a prefabricated wall, such as figure 1 As shown, the preparation process includes the following steps:

[0021] (1) Gypsum board feeding, the gypsum board is transported to the composite platform through the first transport platform;

[0022] (2) The thermal insulation material is loaded, and the thermal insulation material is laid on the gypsum board;

[0023] (3) coating material feeding, laying the coating material on the insulation material;

[0024] (4) On-line production and loading of the keel, making the keel on the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com