Mechanical room and pillar mining method for gentle dip and medium thickness orebody

A kind of technology with gentle slope and medium thickness, mining method, applied in the direction of surface mining, underground mining, special mining, etc., to achieve the effect of high roadway forming speed, ensuring operation safety and low loss and dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

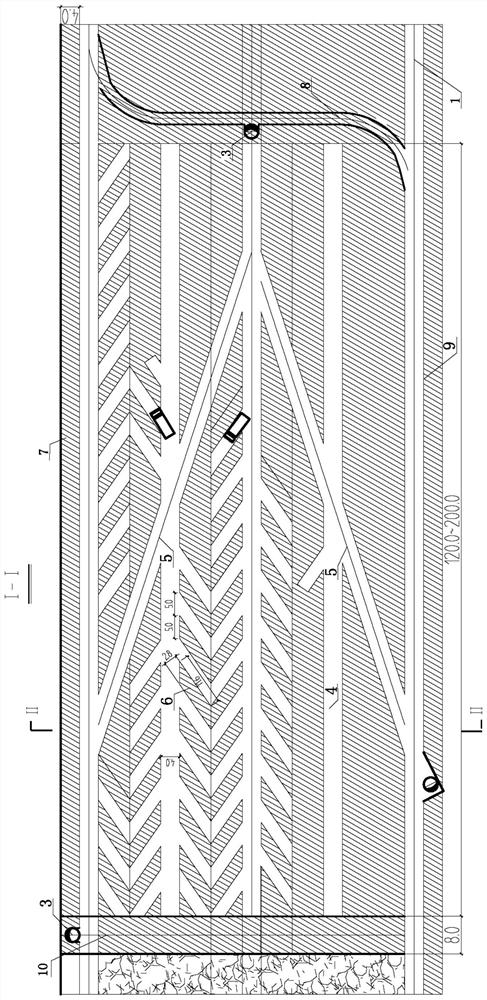

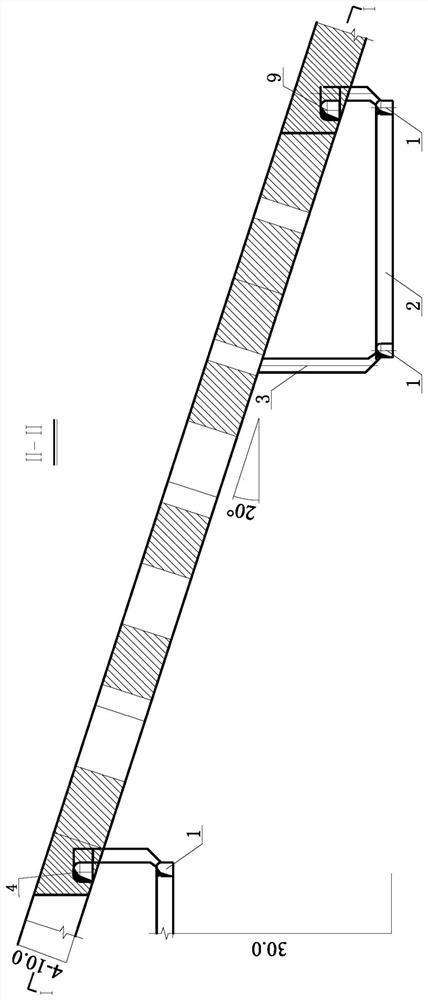

[0025] see figure 1 , figure 2 , a mechanical room-and-pillar mining method for a gently inclined medium-thick ore body, comprising the following steps:

[0026] (1) Mine layout

[0027] The gently inclined medium-thick ore body is divided into several panels along the strike. The panel structure size: along the strike is divided into a panel with a length of 120-200m. 30m. Since this technology adopts the cutting and mining of the roadheader, according to the suitable cutting height of the roadheader, it is determined that there are four layered mining roadways 4 from top to bottom, and the height of the layered mining roadway 4 is 7.5m. Each layered mining roadway 4 Divided into upper and lower halves. An 8.0m isolation ore pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com