Thrust bearing gasket and processing technology thereof

A thrust bearing and processing technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of insufficient lubricating oil and inconvenient lubricating oil staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

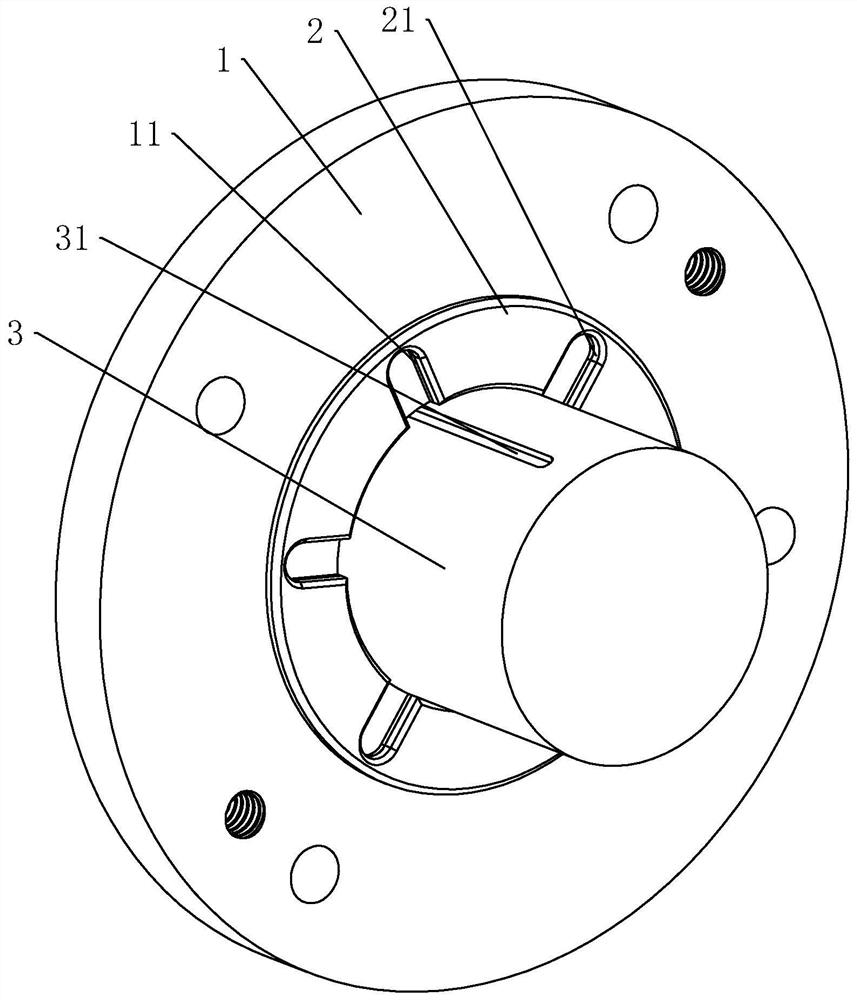

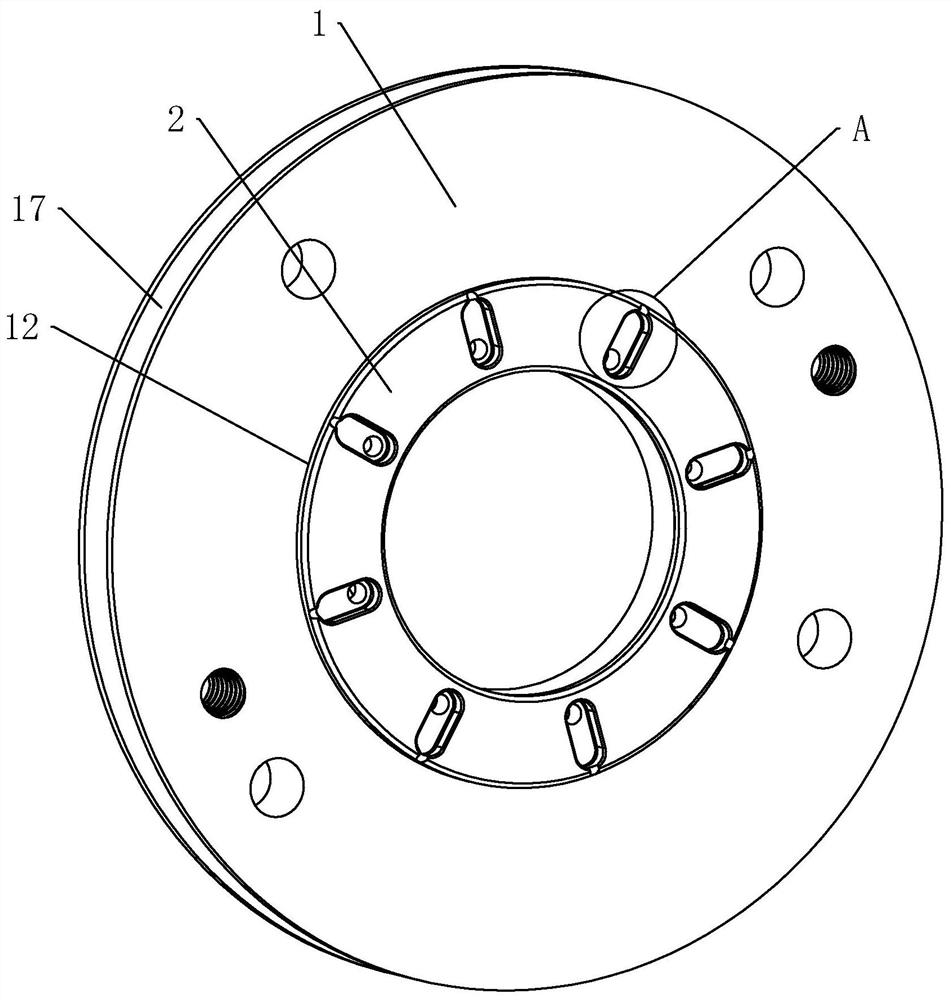

[0044] A kind of thrust bearing spacer, refer to figure 2 , including the gasket body 1, the gasket body 1 is ring-shaped, the side wall of the gasket body 1 is provided with a mounting groove 12 near the inner ring, and the mounting ring 2 is inserted into the mounting groove 12, and the mounting ring 2 interferes with the mounting groove 12 Cooperate.

[0045] refer to figure 2 and Figure 4 , the arc-shaped side wall of the gasket body 1 is provided with an annular groove 17 along the circumferential direction of the gasket body 1, and an injection hole 14 is opened on the groove bottom side wall of the annular groove 17, and the injection hole 14 faces the axis of the gasket body 1. extending in the direction perpendicular to the axial direction of the gasket body 1 , eight injection holes 14 are evenly opened along the circumferential direction of the ring groove 17 .

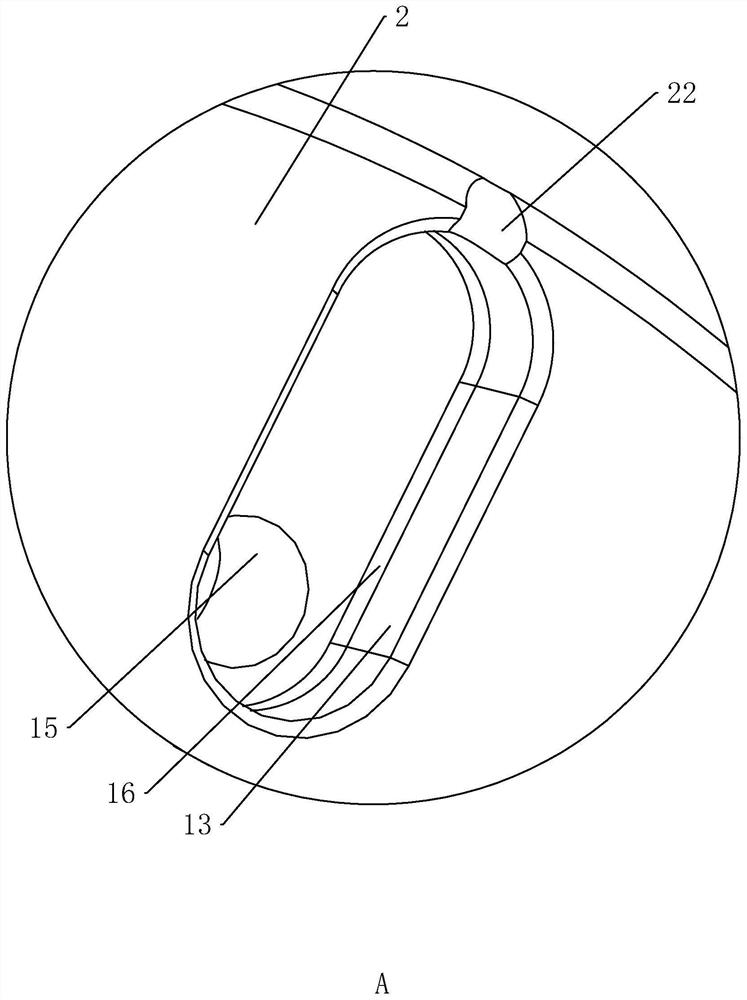

[0046] refer to figure 2 and image 3 , the gasket body 1 is provided with an oil storage tank ...

Embodiment 2

[0053] A kind of processing technology that is applied to the thrust bearing gasket in embodiment 1, with reference to figure 2 with Figure 4 , including the following steps:

[0054] S1: Process gasket body 1:

[0055] S11: rough machining the ring groove 17, and finish turning the ring groove 17;

[0056] S12: Roughly machine the blind hole on the side wall of the ring groove 17 to form the injection hole 14, and then use the boring tool to fine-boring the injection hole 14;

[0057] S13: Machining the oil storage tank 16: use a drill to drill two circular blind holes on the side wall of the gasket body 1, and then use a milling cutter to open the two circular blind holes to form the oil storage tank 16, and then use a boring tool to drill the oil storage tank. 16 for fine boring;

[0058] S14: Machining the overflow groove 22: using a drill bit to drill holes in the oil storage groove 16 to form an overflow hole 15, and then fine boring the overflow hole 15 with a bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com