Industrial refrigeration device for electrical cabinet and using method thereof

A technology for industrial refrigeration and electrical cabinets, which is applied to structural components of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., and can solve problems such as time-consuming, increased labor intensity of maintenance personnel, and damage to electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

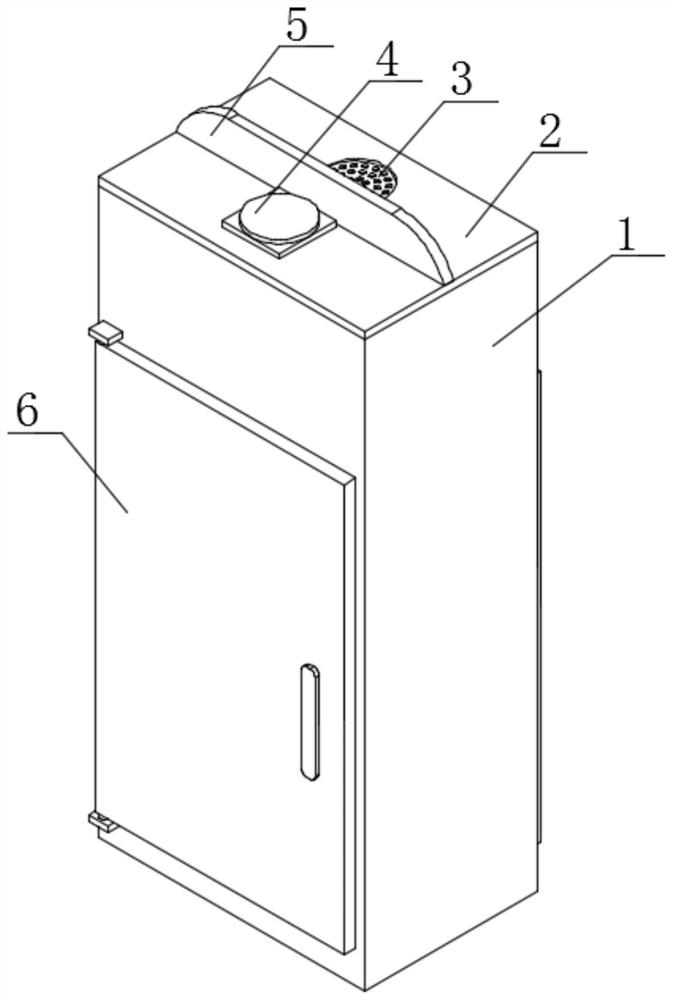

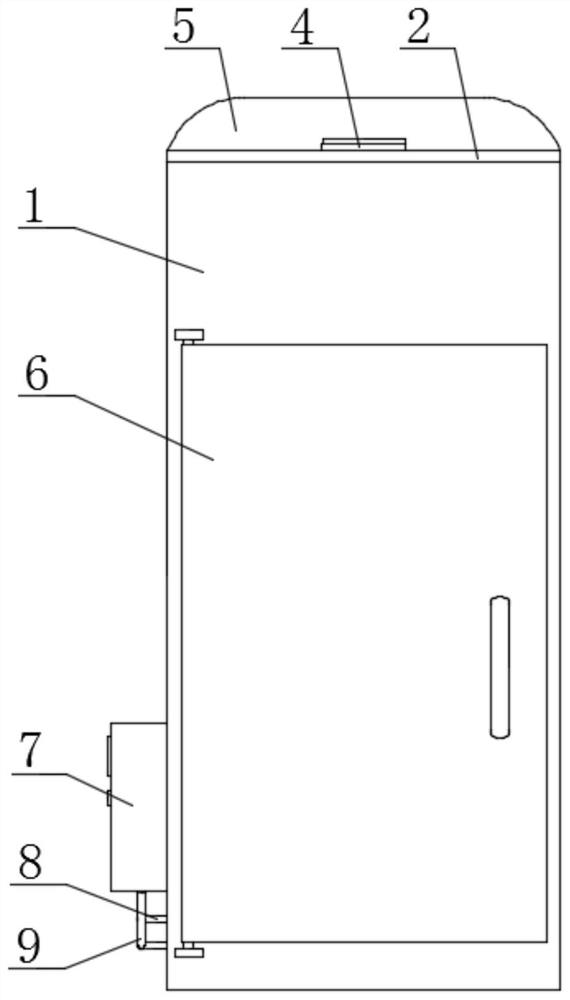

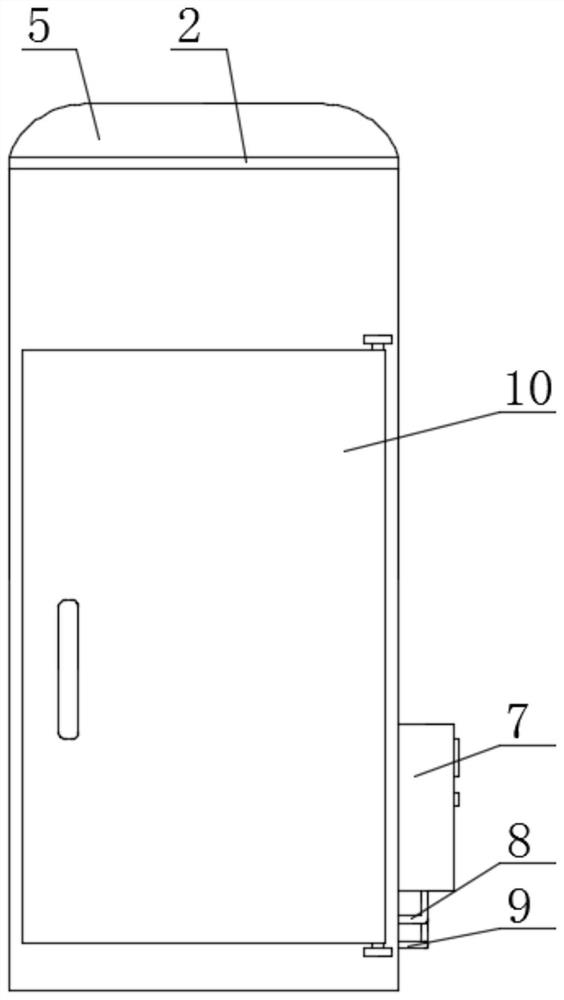

[0058] Embodiment one: if Figure 1-20 As shown, an industrial refrigeration equipment for electrical cabinets includes a cabinet body 1, door openings 15 are arranged on both sides of the cabinet body 1, and front door panels 6 and rear door panels 10 are respectively hinged on both sides of the cabinet body 1. Backboards 14 are fixedly installed on the inner walls of both sides and the inner wall of the bottom. The top of the cabinet body 1 is welded with a top cover 2. The bottom of the top cover 2 is in contact with the top of the backplane 14. The backplane 14 is close to the side of the front door panel 6. A plurality of electrical component mounting plates 16 arranged at equal intervals are fixedly installed, two support plates 11 are welded symmetrically on the top and bottom of the other side of the back plate 14, and two first racks are welded symmetrically on one side of the back plate 14 21. The same guide post 19 is welded on the sides of the two support plates 11...

Embodiment 2

[0072] Embodiment two: if Figure 21-25 As shown, an industrial refrigeration equipment for electrical cabinets, the difference between this embodiment and Embodiment 1 is: a horizontal plate 44 is welded on the top of one side of the back plate 14, and the top of the horizontal plate 44 is provided with a third through hole, and the third The inner wall of the through hole is slidably connected with a guide rod 36, and the top of the guide rod 36 passes through the third through hole, the first circular hole 47 and the filter plate 3 respectively and extends to the top of the top cover 2, and the top of the guide rod 36 is fixed. Sealing box 33 is installed, and the bottom of sealing box 33 contacts with the top of top cover 2, and the outer wall of guide rod 36 is vertically welded with round bar 37, and the top side of round bar 37 is welded with moving bar 45, and the side of moving bar 45 The top runs through the horizontal plate 44 and extends to the top of the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com