A copper-silicon catalyst modified by silanization of a tertiary amino-containing silane coupling agent and its preparation method and application

A technology of tertiary amino silane coupling agent silane and tertiary amino silane coupling agent, which is applied in the field of copper-silicon catalyst and its preparation, gas-phase ester hydrogenation catalyst, and can solve the problem of separation cost and energy consumption increase, copper species Catalyst deactivation, catalyst coking deactivation and other problems, to achieve the effect of reducing the selectivity of by-products, improving stability and conversion frequency, and promoting desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

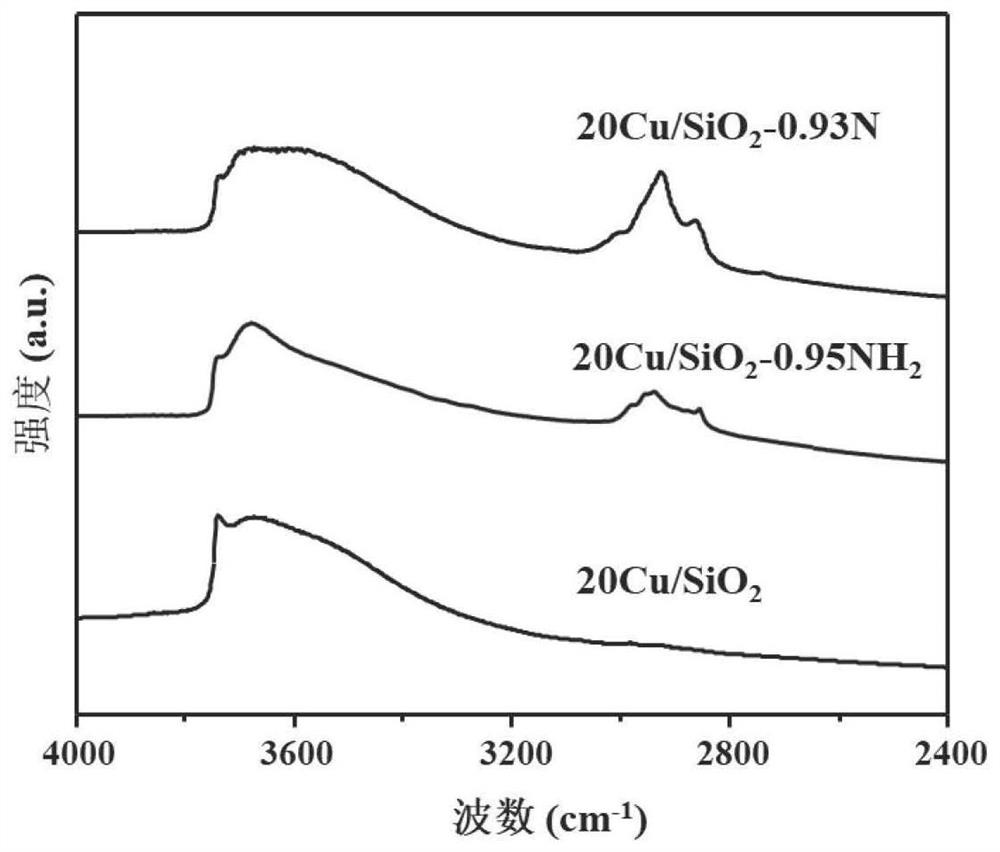

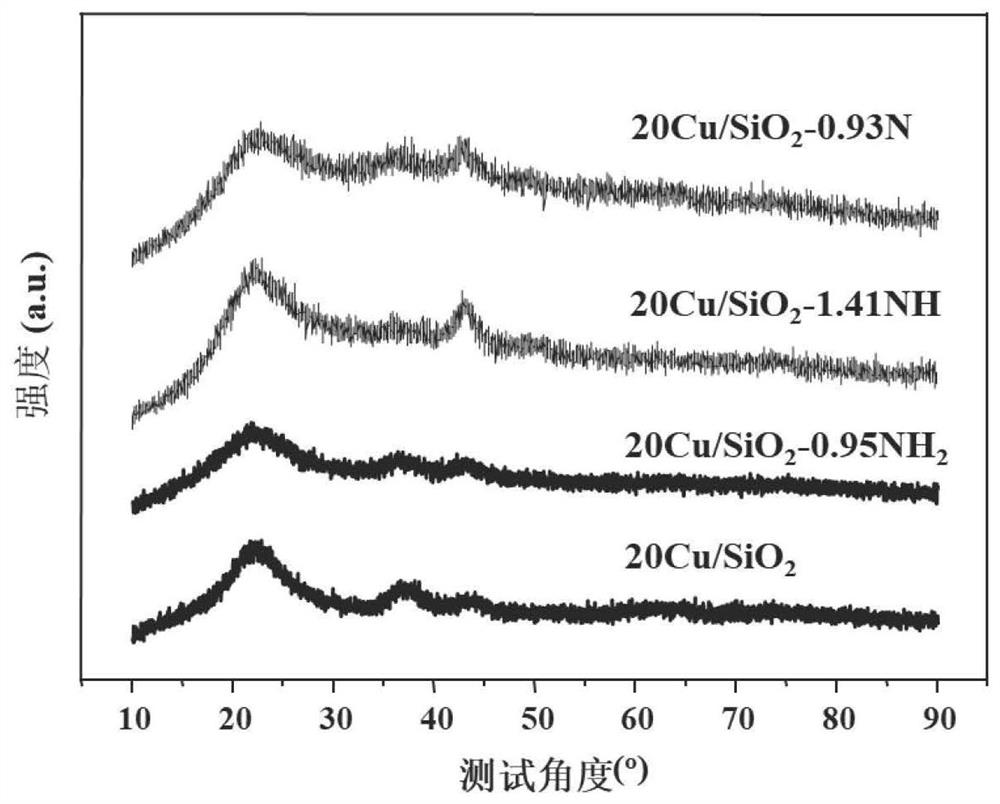

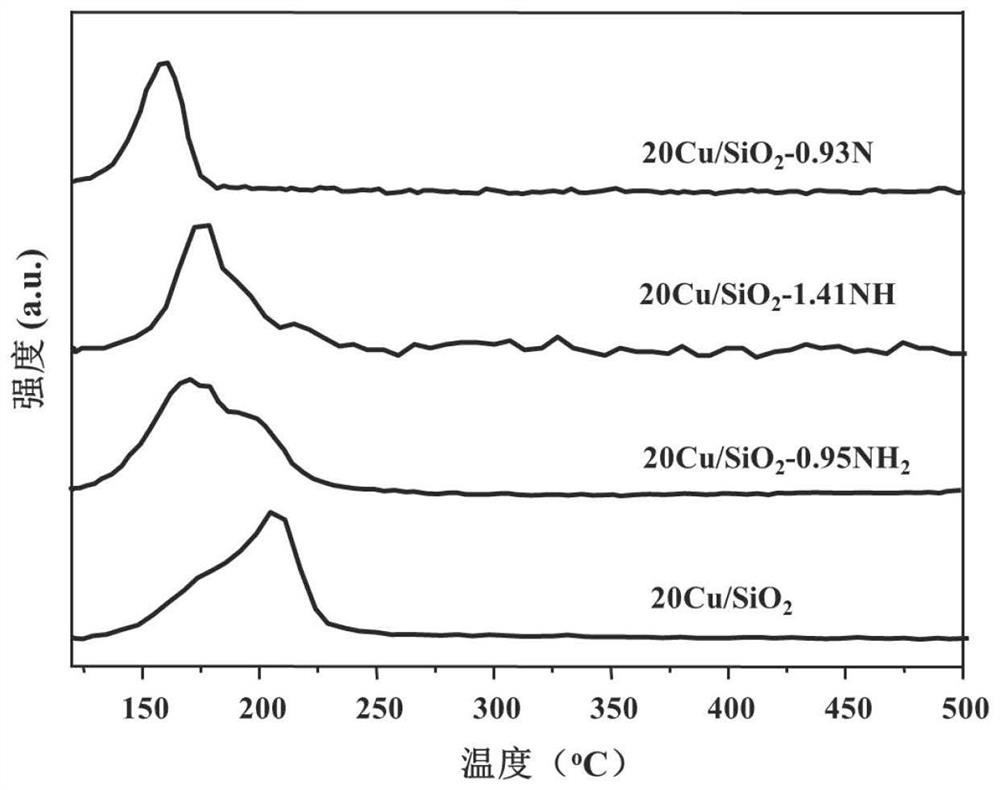

[0041] Example 1-3: 10Cu / SiO 2 -0.93N, 20Cu / SiO 2 -0.93N, 30Cu / SiO 2 -0.93N

[0042] Embodiment 1-3 is 10Cu / SiO 2 -0.93N, 20Cu / SiO 2 -0.93N, 30Cu / SiO 2 - Preparation of 0.93N with 10Cu / SiO 2 -0.93N means that the copper metal loading in the ammonia-distilled copper-silicon catalyst is 10wt.%, the nitrogen element accounts for 0.93wt.% of the catalyst weight, and the modified group includes a tertiary amino group, 20Cu / SiO 2 -0.93N, 30Cu / SiO 2 -0.93N and 10Cu / SiO 2 -0.93N differs only in copper loading. The active species copper loading and nitrogen element content in the catalyst of the present invention are respectively characterized by an inductively coupled plasma emission spectrometer and an elemental analyzer.

[0043] The specific preparation method is as follows: Weigh 1g 10Cu / SiO 2 , 20Cu / SiO 2 and 30Cu / SiO 2 Dissolve in 125mL of anhydrous methanol, add 0.0867g of N,N-diethylaminopropyltrimethoxysilane dropwise at 30°C, raise the temperature to 80°C after t...

Embodiment 4-5

[0044] Example 4-5: 20Cu / SiO 2 -1.41NH, 20Cu / SiO 2 -0.95NH 2

[0045] Embodiment 4-5 is 20Cu / SiO 2 -1.41NH, 20Cu / SiO 2 -0.95NH 2 Preparation, where 20Cu / SiO 2 -1.41NH means that the copper loading in ammonia-distilled copper-silicon catalyst is 20wt.%, the nitrogen element accounts for 1.41wt.% of the catalyst weight, and the modification group does not contain tertiary amino groups but contains secondary amino groups. 20Cu / SiO 2 -0.95NH 2 The modifying group only contains primary amino groups, the copper metal loading in the ammonia-distilled copper-silicon catalyst is 20wt.%, and the nitrogen element accounts for 0.95wt.% of the weight of the catalyst.

[0046] The specific preparation method is as follows: 1g 20Cu / SiO 2 Dissolve in 125mL of anhydrous methanol, add 0.368mmol nitrogen-containing silane coupling agent dropwise at 30°C, that is, add 0.0819g N-(2-aminoethyl)-3-aminopropyltrimethoxy dropwise Silane or 0.0660g of 3-aminopropyltrimethoxysilane, after the d...

Embodiment 6-7

[0047] Example 6-7: 20Cu / SiO 2 -0.27N, 20Cu / SiO 2 -1.65N

[0048] Embodiment 6-7 is 20Cu / SiO 2 -0.27N, 20Cu / SiO 2 - Preparation of 1.65N with 20Cu / SiO 2 -0.27N means that the copper metal loading in the ammonia-distilled copper-silicon catalyst is 20wt.%, the nitrogen element accounts for 0.27wt.% of the catalyst weight, and the modified group includes a tertiary amino group, 20Cu / SiO 2 -Nitrogen in 1.65N accounts for 1.65wt.% of catalyst weight, others are the same as 20Cu / SiO 2 -0.27N is the same.

[0049] The specific preparation method is as follows: 1g 20Cu / SiO 2 Dissolve in 125mL of anhydrous methanol, add 0.0095g and 0.1844g of N,N-diethylaminopropyltrimethoxysilane dropwise at 30°C respectively, raise the temperature to 80°C after the dropwise addition, and stir at reflux for 6h. The cooled solution was centrifugally washed and dried overnight at 80° C. to obtain a copper-silicon catalyst modified with a tertiary amino silane coupling agent. The catalyst is pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com