Long-line die table prefabricated component edge template fixing device and long-line die table comprising long-line die table prefabricated component edge template fixing device

A technology of prefabricated components and fixing devices, applied in the direction of molds, etc., can solve the problems of occupying a large space of the mold table, reducing the utilization rate of the mold table, increasing the magnet adsorption force, etc., achieving small adsorption force requirements, reducing the number of magnetic boxes, and reducing side shift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

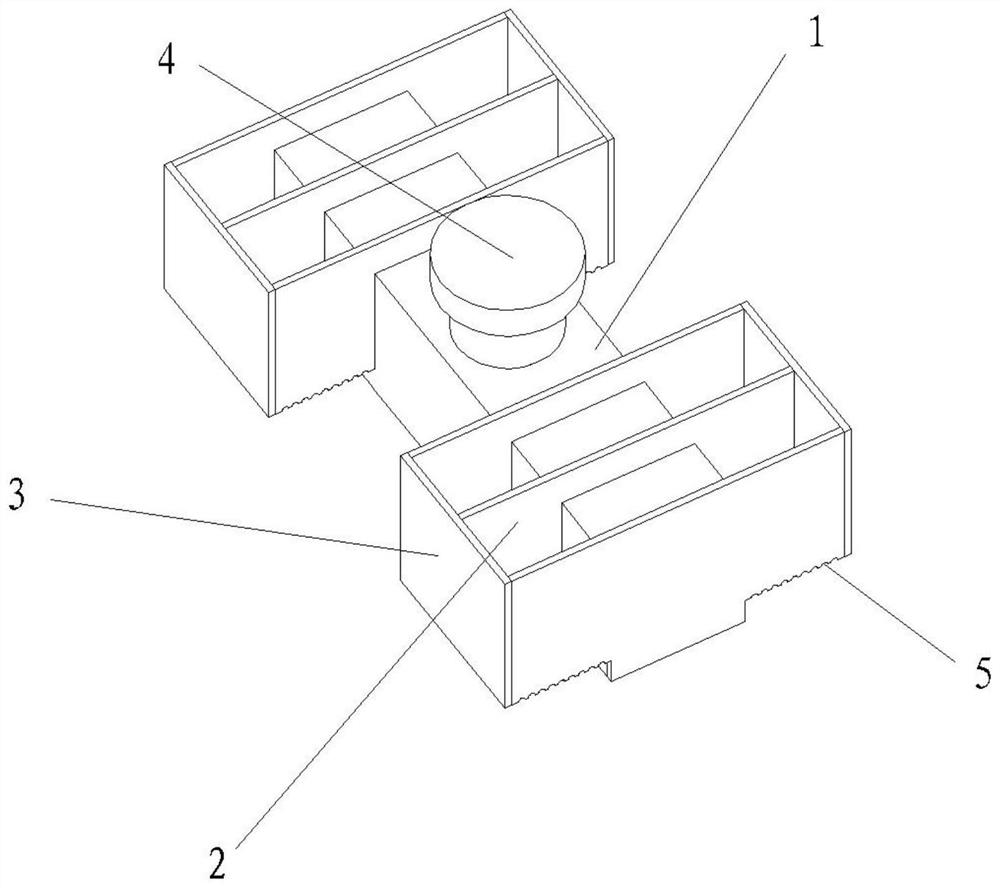

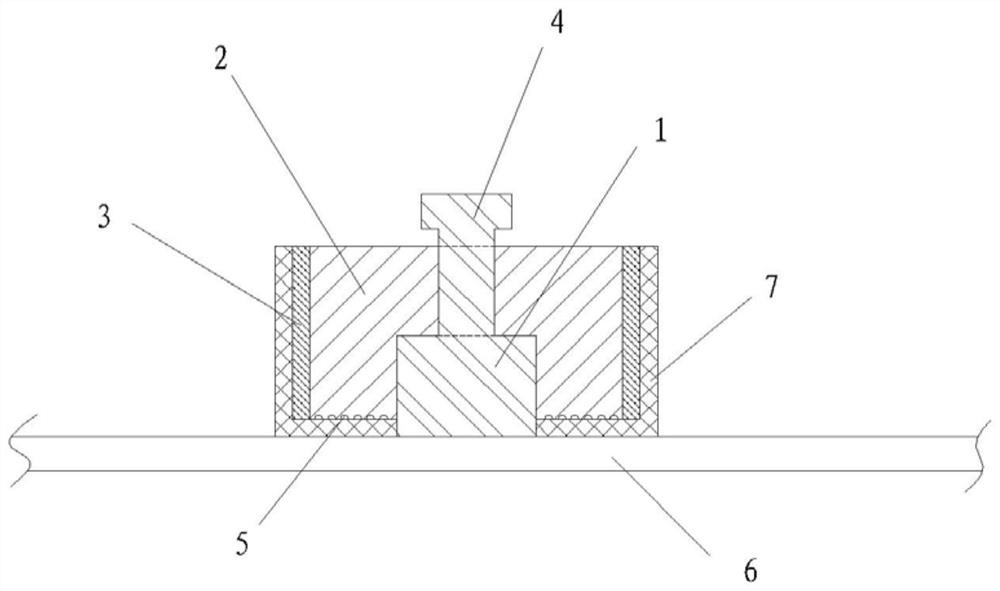

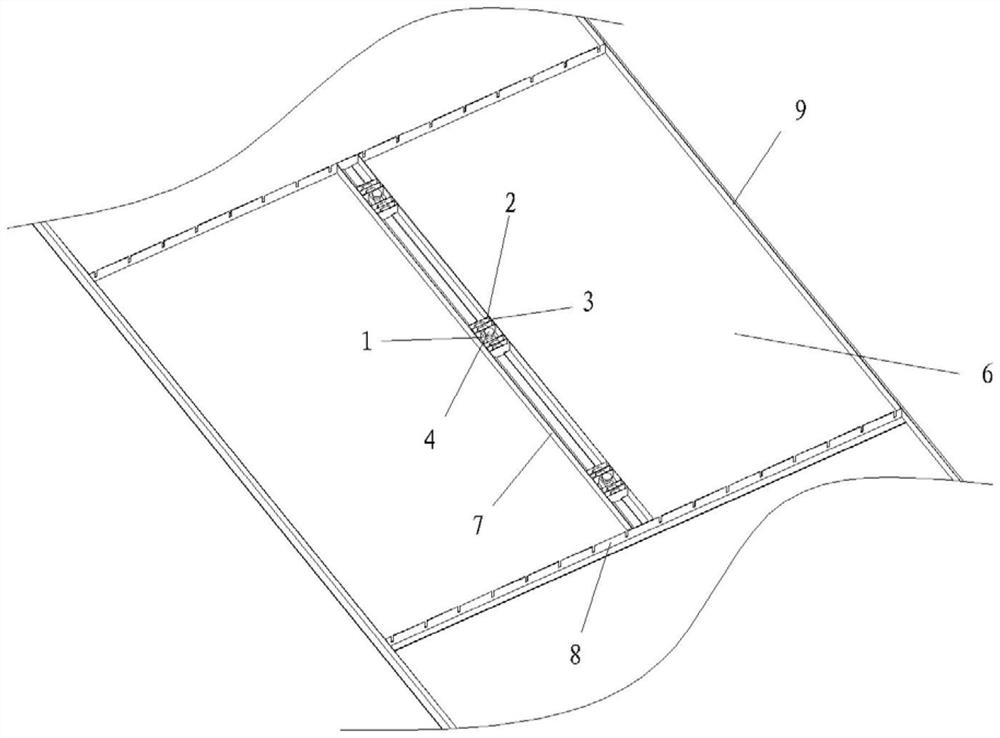

[0025] see figure 1 and figure 2 , the present invention provides a side formwork fixing device for prefabricated components of a long-line formwork table, which includes a magnetic box 1, formwork support ribs 2 and side plates 3, the magnetic box 1 is in the shape of a cuboid, and a magnetic box is arranged in the center of the upper surface of the magnetic box 1. The box switch 4 is used to control the opening or closing of the magnetic box 1 . A template support rib 2 is welded and fixed along the length direction of the magnetic box 1 , and the template support rib 2 is sheet-shaped and perpendicular to the length direction of the magnetic box 1 . In this embodiment, the number of the template support ribs 2 is six, and the six template support ribs 2 are divided into two groups, which are respectively welded to both ends of the magnetic box 1 in the longitudinal direction. The three formwork support ribs 2 of each group are arranged with the same spacing, and the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com