A mask detection device and automatic mask production line

A detection device and production line technology, which is applied to sewing tools, sorting, household appliances, etc., can solve the problems of oversize or undersize, damage of qualified parts, and low inspection efficiency, so as to improve work efficiency and improve inspection efficiency. Efficiency and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

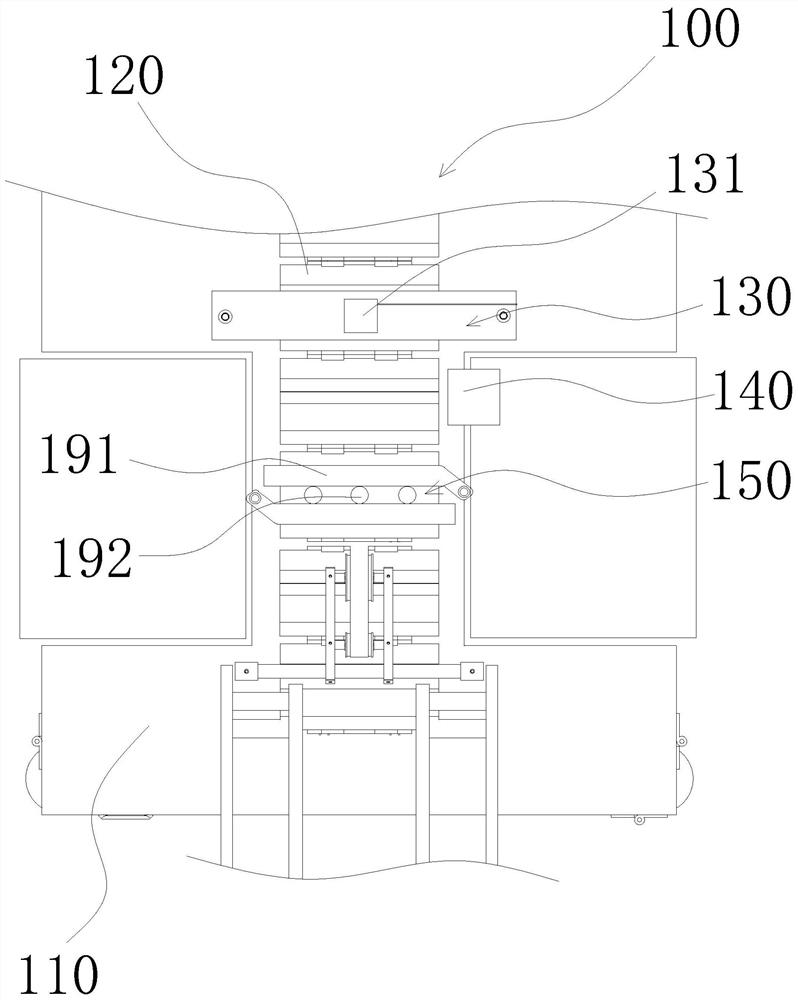

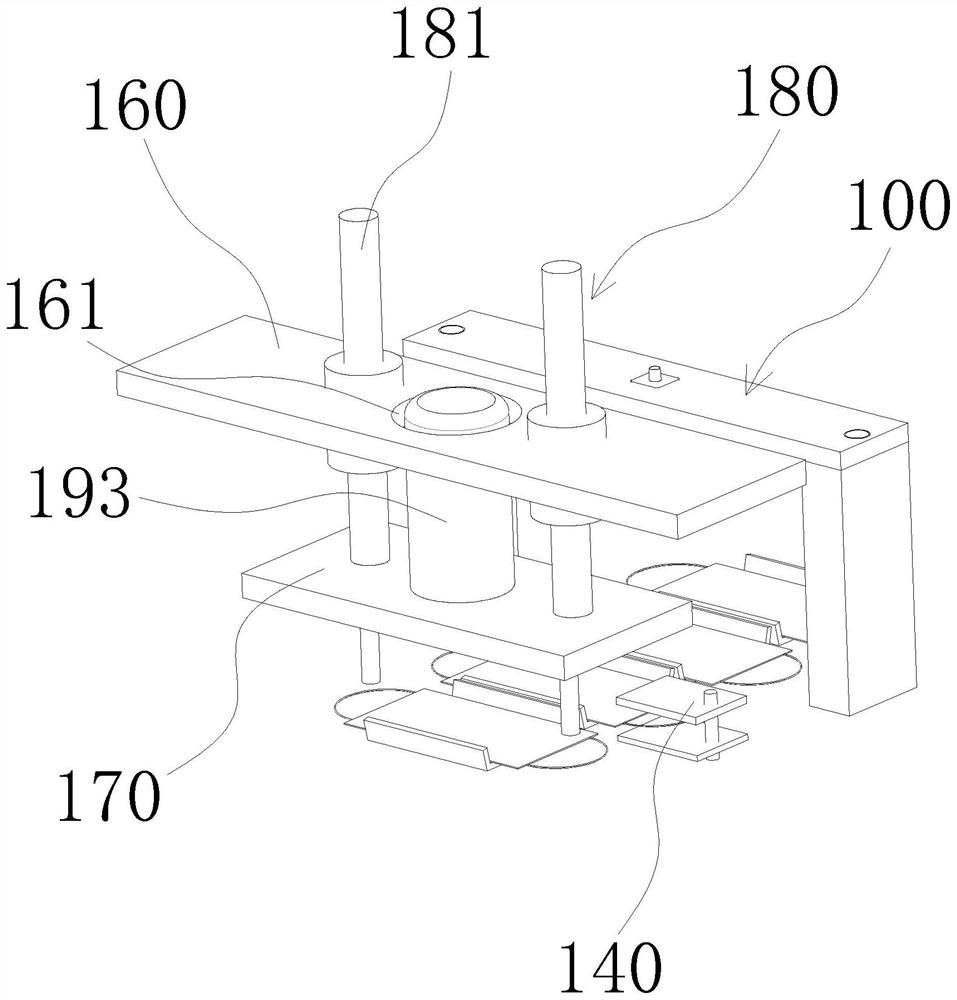

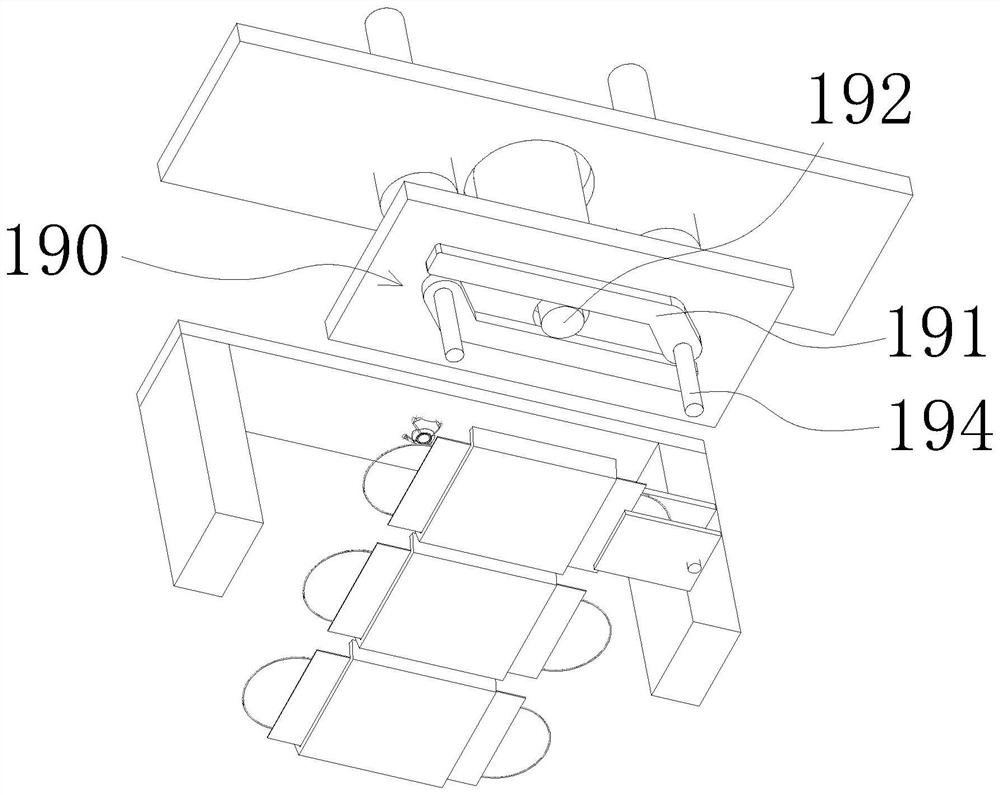

[0041] like Figure 1-8 As shown, the present invention provides a mask detection device 100 , including a detection workbench 110 , an ear wire identification mechanism 130 , a mask clamping mechanism and a stretch detection mechanism 150 .

[0042] The detection workbench 110 is provided with a conveyor belt 120 on the detection workbench 110, and the masks are placed on the conveyor belt 120 by a tray for transportation.

[0043] The ear wire recognition mechanism 130 is arranged above the conveyor belt 120. As the first detection process, the ear wire recognition mechanism 130 is provided with a camera 131 to image and identify the position of the ear wire of the mask. Due to the simple structure of the mask, the color of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com