Assembled wall top packaging structure and installation method thereof

A packaged structure and prefabricated technology, applied to walls, building components, building structures, etc., can solve the problems of reducing the stability and safety of prefabricated walls, poor fire resistance of styrofoam, and low installation strength, etc., to achieve improved Effects of stability and safety, enhanced structural strength, and simple installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

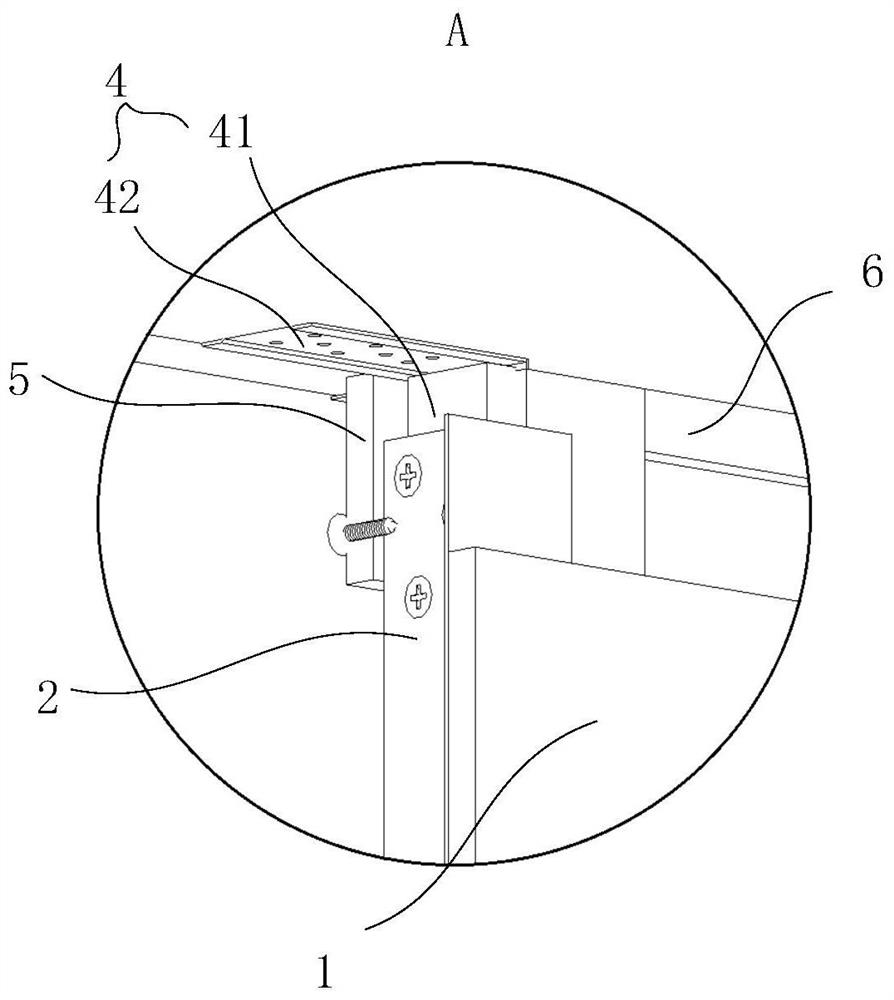

[0043] In some embodiments, referring to Figure 7 , the fixing member 4 includes a first fixing member 4a, the number of fixing plates 42 of the first fixing member 4a is two, and the two fixing plates 42 are respectively connected to the ends of the two side plates 411 . The two fixing plates 42 of the first fixing member 4a both extend in a direction perpendicular to the main wall, which will not affect the installation between two adjacent wall modules 100, or the installation between the wall module 100 and the side wall of the building. Based on this, the first fixing member 4 a can be installed on the top of any overlapping profile 2 of any wall module 100 . The number of fixing plates 42 is two, which can enhance the reliability of the connection between the fixing member 4 and the building roof. Exemplarily, the first fixing member 4a can be installed on the top of any overlapping profile 2 of the starting wall module, the middle wall module and the trailing wall mod...

Embodiment 2

[0046] In other embodiments, refer to Figure 8 , the fixing part 4 further includes a second fixing part 4b, the number of the fixing plate 42 of the second fixing part 4b is one, and the fixing plate 42 is connected to the end of the connecting plate 412 . Compared with the first fixing part 4a, the second fixing part 4b has no visible fixing plate 42 exposed on the building roof, which will not affect the surface decoration of the building roof. Moreover, the number of fixing plates 42 is less, and the manufacturing cost of the fixing member 4 is lower. However, since the fixing plate 42 extends parallel to the prefabricated wall, it can only be used on the top of the overlapping profile 2 on the side of the wall module 100 away from the starting end. Based on this, the second fixing part 4b needs to be used together with the first fixing part 4a. Exemplarily, the first fixing member 4a is used on the top of the overlapping profile 2 of the starting end wall module and th...

Embodiment 3

[0050] In some embodiments, referring to Figure 9 , the fixing part 4 also includes a third fixing part 4c, the number of the fixing plates 42 of the third fixing part 4c is two, one of the two fixing plates 42 is connected with the end of the connecting plate 412, and the other is connected with one of the side The ends of the plates 411 are connected. Usually, the two sides of the main wall correspond to indoor and outdoor respectively, and the third fixing part 4c takes into account the advantages of the first fixing part 4a and the second fixing part 4b, and the fixing plate 42 connected with the connecting plate 412 is located on the side of the main wall close to the outdoor The roof of the building will not affect the surface decoration of the roof of the building. The number of fixing plates 42 is two, which can ensure the connection strength between the fixing member 4 and the building roof. The use of the third fixing member 4c is similar to that of the second fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap