Split herringbone gear and planetary transmission device thereof

A technology of herringbone gear and planetary transmission, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of difficult installation, large fluctuations in stiffness, and difficult processing of herringbone gears, etc., and achieve planetary gear uniformity Good load condition and controllable stiffness fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more obvious and understandable, a detailed description is given as follows with preferred embodiments and accompanying drawings:

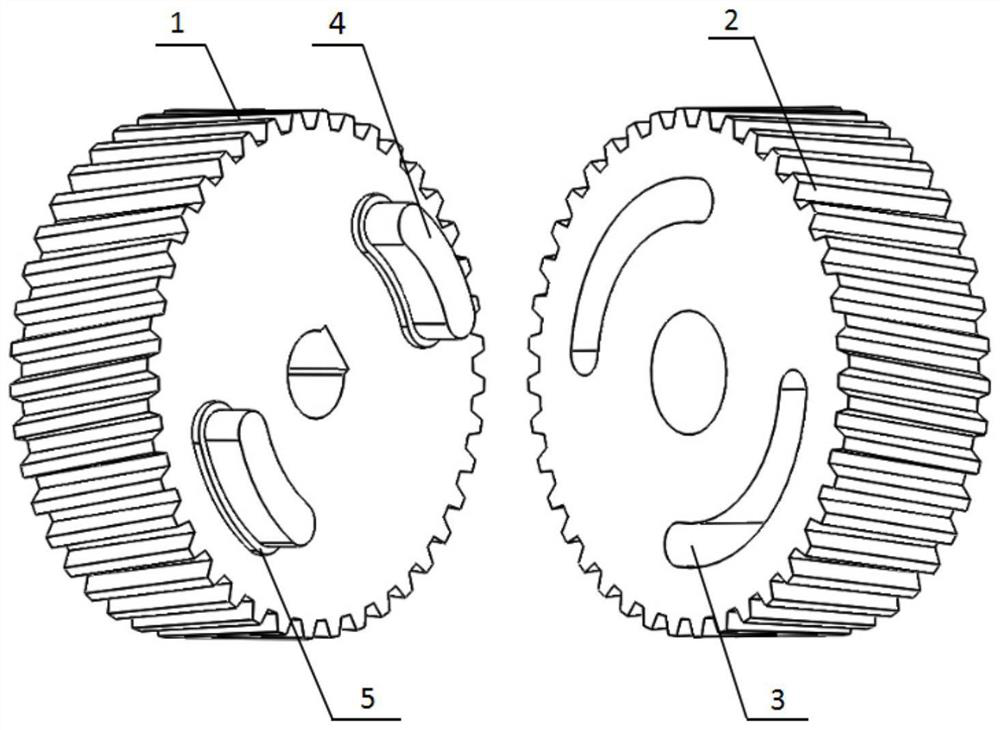

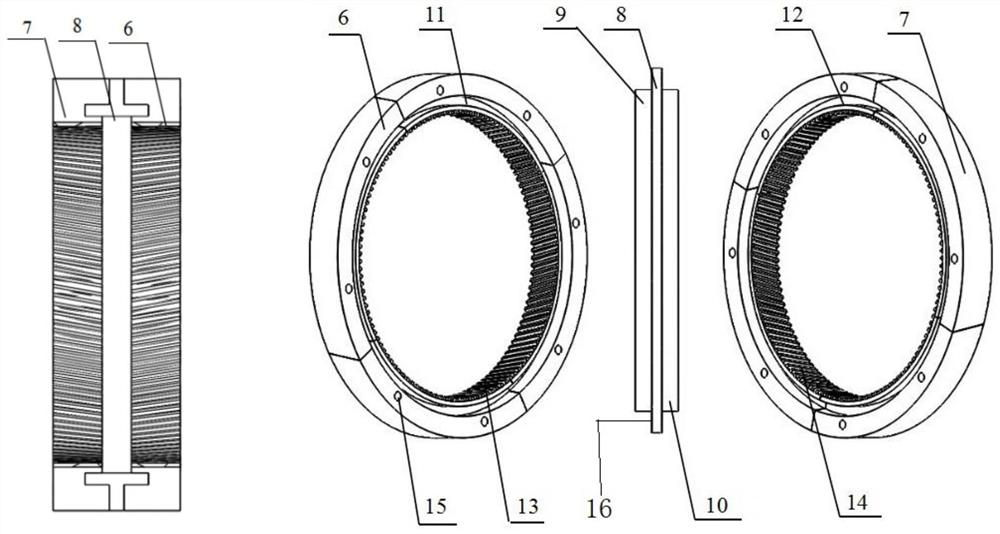

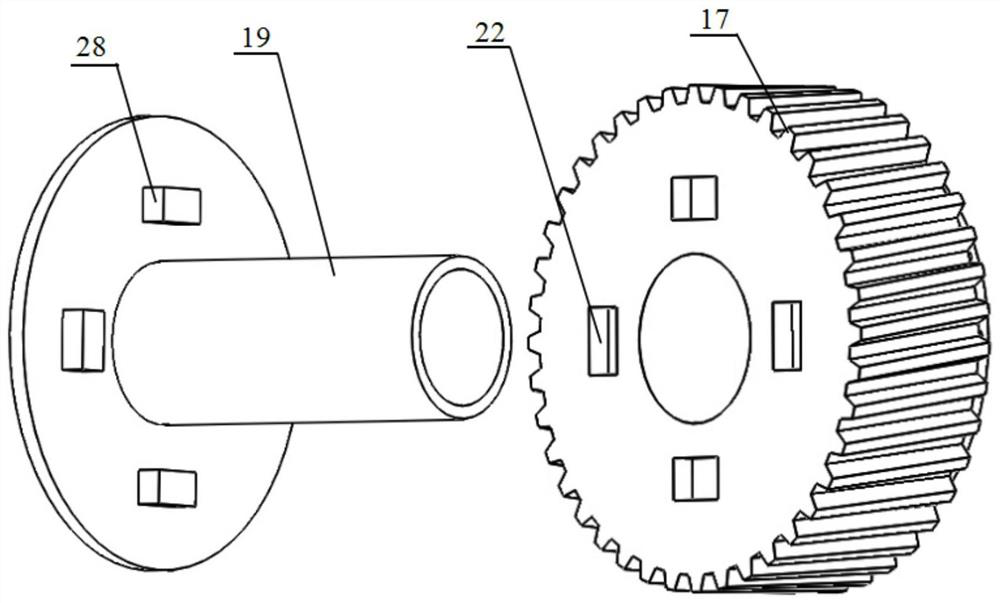

[0026] Such as Figure 1-6 As shown, the present invention provides a split herringbone gear and its planetary transmission device, including a radially segmented and assembled herringbone internal gear 222, an axially separated herringbone external gear 111, and a human with equal load effect. A planetary gear 333 and a planet carrier; a herringbone planetary gear 333 is provided on the radially segmented and assembled herringbone internal gear 222, and different herringbone planetary gears 333 are connected by a planet carrier; an axially separated herringbone The tooth external gear 111 is in meshing connection with the herringbone planetary gear 333. The axially separated herringbone external gear 111 includes a left-handed external gear 1, a right-handed external gear 2 and a ring gasket 5; the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com