Dustproof shell of LED packaging light source with high light efficiency

A technology of LED encapsulation and dust-proof casing, which is applied to the loss prevention measures of lighting devices, light sources, and components of lighting devices, etc., can solve the problem of reducing the life of LED light decay, reducing the reliability of the whole lamp product, and affecting the performance of the whole lamp product. and other problems to avoid mosquito bites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

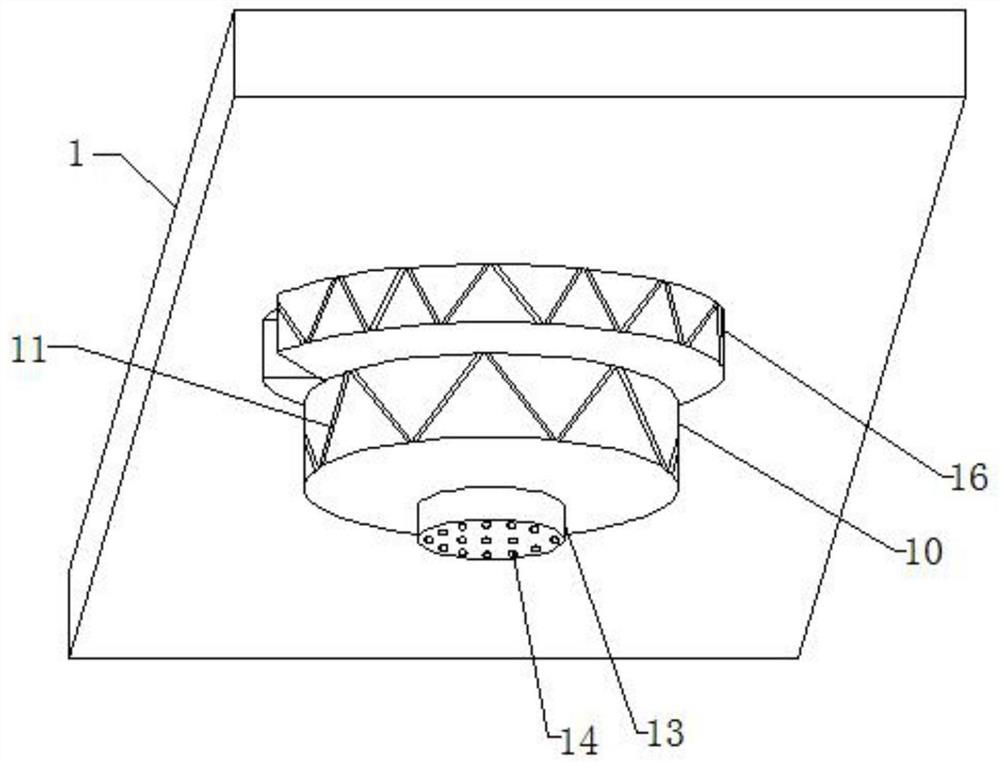

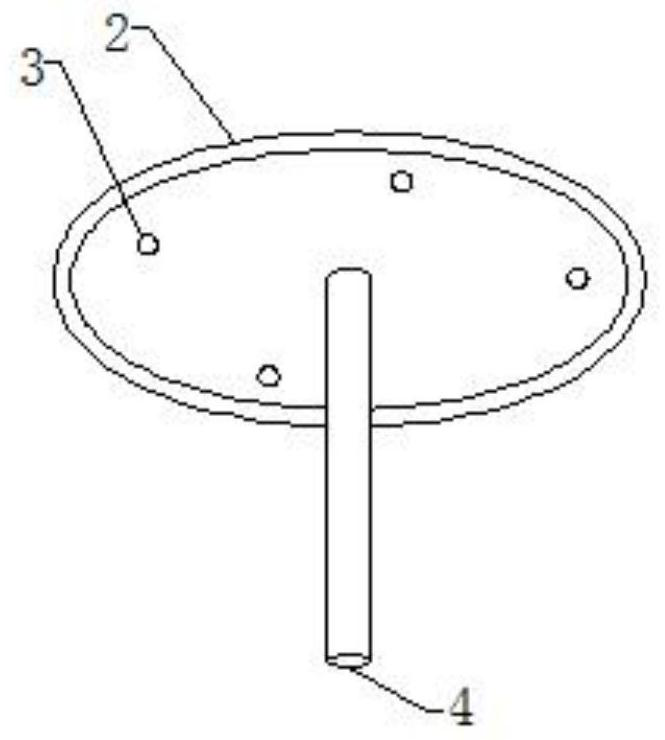

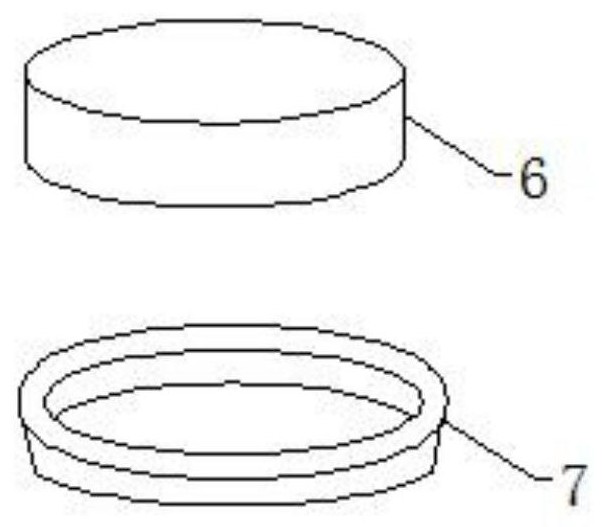

[0032] refer to Figure 1-8 , a dust-proof housing for a high-efficiency LED packaged light source, comprising a housing 1, a circular hanger 2 connected to the top inner wall of the housing 1 by bolts, and a plurality of positioning holes 3 are opened on the outer wall of the bottom of the circular hanger 2, and the circular The middle position of the bottom outer wall of the shaped hanger 2 is fixedly connected with a first fixed shaft 4, and the end of the first fixed shaft 4 away from the circular hanger 2 is plugged with an engine base 6, and the bottom outer wall of the engine base 6 is fixedly connected with an outlet. The air ring cavity 7, the end of the first fixed shaft 4 far away from the circular hanger 2 is clamped with the LED light tube connector 8, the end of the LED light tube connector 8 far away from the first fixed shaft 4 is fixedly connected with the LED ring light tube 9, and the engine The outer wall of the bottom of the base 6 is clamped with an LED l...

Embodiment 2

[0040] refer to Figure 9 , a dust-proof housing for a high-efficiency LED packaged light source. Compared with Embodiment 1, this embodiment also includes a switch timer 28 and a Bluetooth speaker 27. Both the switch timer 28 and the Bluetooth speaker 27 are fixedly connected to the shell 1. On the outer wall of the bottom, the switch timer 28 and the Bluetooth speaker 27 are located on both sides of the hollow shell 16 of the ultraviolet lamp tube.

[0041] When in use, the bluetooth audio system 27 is connected to the device through bluetooth, and can broadcast voice, and the timer switch 28 is used to set the switching time to turn on and off the device without manual operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com