Vertical heat exchanger

A heat exchanger, vertical technology, applied in the field of vertical heat exchangers, can solve the problem of local heating of the upper tube sheet, and achieve the effect of solving local heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

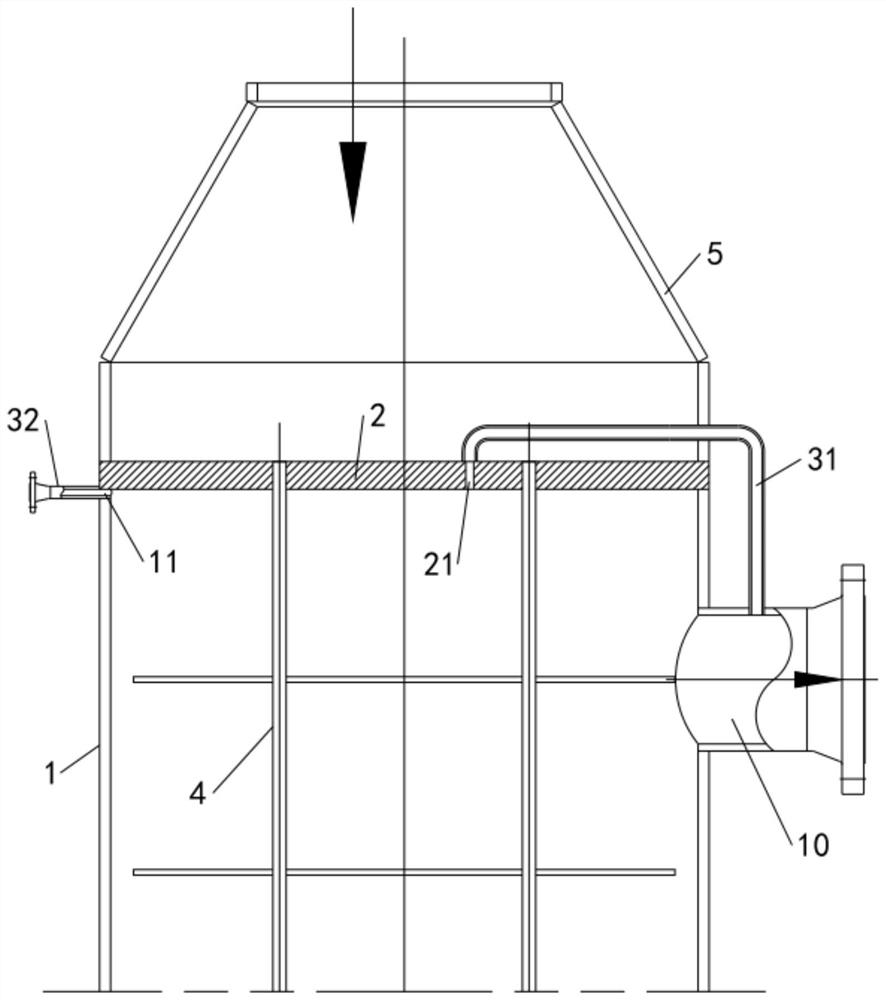

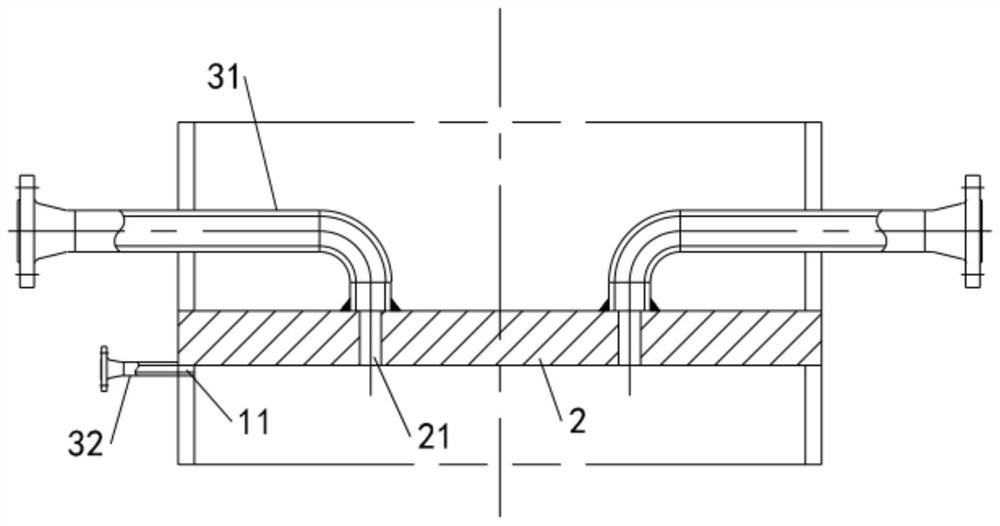

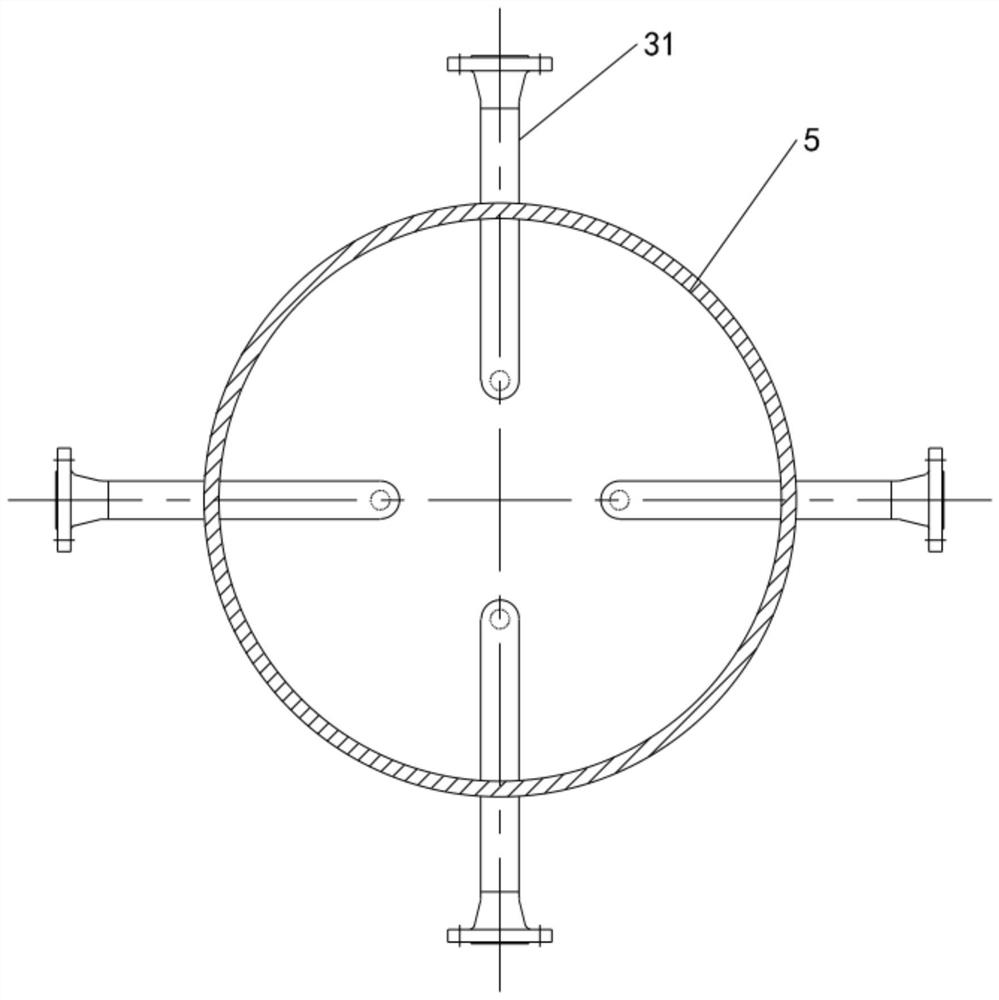

[0039] Such as figure 1 As shown, this embodiment provides a vertical heat exchanger, including a cylinder 1 with upper and lower ends open, an upper tube plate 2 for closing the opening at the upper end of the cylinder 1, and an upper tube plate 2 for closing the opening at the upper end of the cylinder 1. The lower tube plate with the opening at the lower end, the vertical heat exchanger also includes an upper tube box 5, a lower tube box and a plurality of heat exchange tubes 4, the upper tube box 5 is connected to the upper tube plate 2, and the lower tube box is connected to the lower tube plate , the upper tube box 5 is provided with a tube-side inlet, the lower tube box is provided with a tube-side outlet, the upper part of the cylinder body 1 is provided with a shell-side outlet 10, and the lower part of the cylinder body 1 is provided with a shell-side inlet; a plurality of heat exchange tubes 4 vertical One end of each heat exchange tube 4 is connected to the upper t...

Embodiment 2

[0048] The difference between this embodiment and the first embodiment lies in that the structure for exhausting the air below the piping area is different. Such as Figure 4 and Figure 5As shown, in this embodiment, a plurality of heat exchange tubes 4 are distributed according to a preset distribution form to form a gas flow channel 12, and the gas flow channel 12 communicates with the area of the cylinder 1 directly below the edge area and directly below the pipe layout area .

[0049] In this embodiment, the second exhaust hole 11 communicates with the gas flow channel 12, and the gas in the cylinder 1 is led out through the gas flow channel 12, the second exhaust hole 11, and the second exhaust pipe 32, and at the same time realizes the piping area Exhaust below and below the edge area. In other embodiments, the first exhaust hole 21 can also be communicated with the gas flow channel 12 , and the gas inside the barrel 1 is led out through the gas flow channel 12 , t...

Embodiment 3

[0054] The difference between the present embodiment and the first embodiment lies in that the structure for exhausting the air below the edge area is different. Such as Figure 6 As shown, the exhaust structure includes a third exhaust hole 13 and a third exhaust pipe 33, wherein the third exhaust hole 13 is arranged on the cylinder body 1 and has a distance from the lower surface of the upper tube plate 2, One end of the third exhaust pipe 33 is inserted into the third exhaust hole 13 and connected to the cylinder body 1 for sending the gas under the edge area to the outside of the cylinder body 1 . It should be noted that the third exhaust pipe 33 may directly communicate with the outside atmosphere, or communicate with the shell side outlet 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com