Goods circulation tracking and supervising system based on supply chain

A technology of goods circulation and supervision system, applied in the field of supply chain goods monitoring, can solve problems such as affecting processing efficiency, slow scanning speed, falling, etc., to achieve the effect of improving accuracy and convenience, improving speed and reducing trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

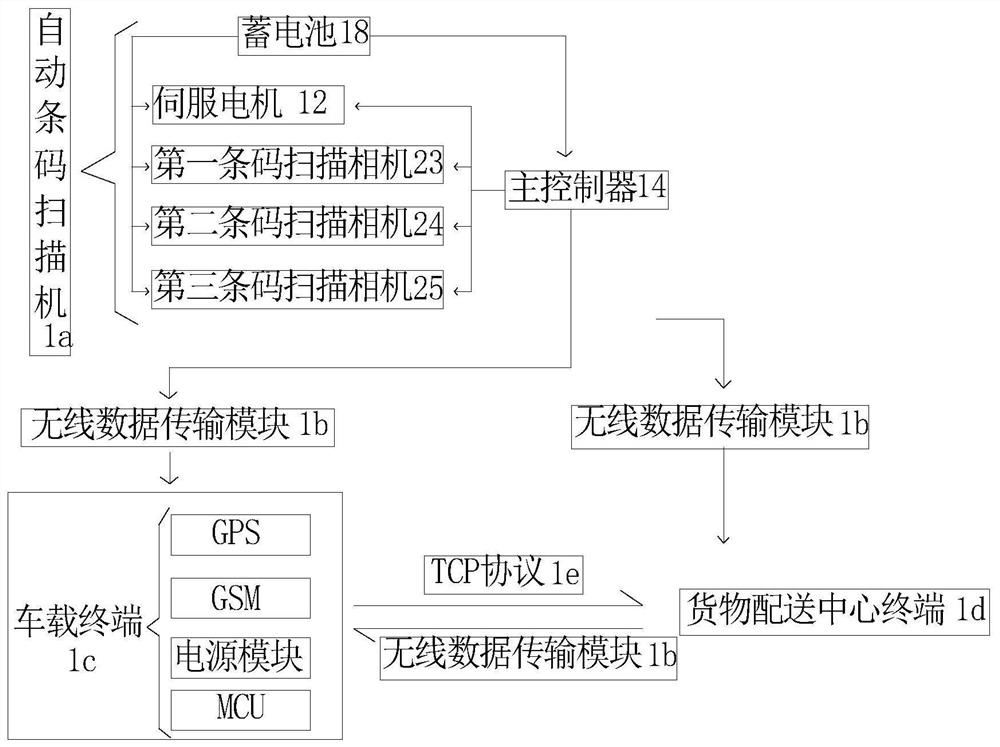

[0048] see figure 1 , a goods circulation tracking supervision system based on the supply chain, including an automatic barcode scanning machine 1a, a wireless data transmission module 1b, a vehicle-mounted terminal module 1c and a cargo distribution center terminal 1d, the automatic barcode scanning machine 1a communicates with the vehicle-mounted terminal through the wireless data transmission module 1b The terminal module 1c is wirelessly connected, the vehicle-mounted terminal module 1c is wirelessly connected to the cargo distribution center terminal 1d through the wireless data transmission module 1b, and communicates with each other through the TCB protocol 1e, and the automatic barcode scanning machine 1a includes a conveying mechanism 1 and a code scanning mechanism 2, The code scanning mechanism 2 is installed on the upper end of the conveying mechanism 1; after the goods are scanned and input by the automatic barcode scanner 1a, they are transmitted to the vehicle-mo...

Embodiment 2

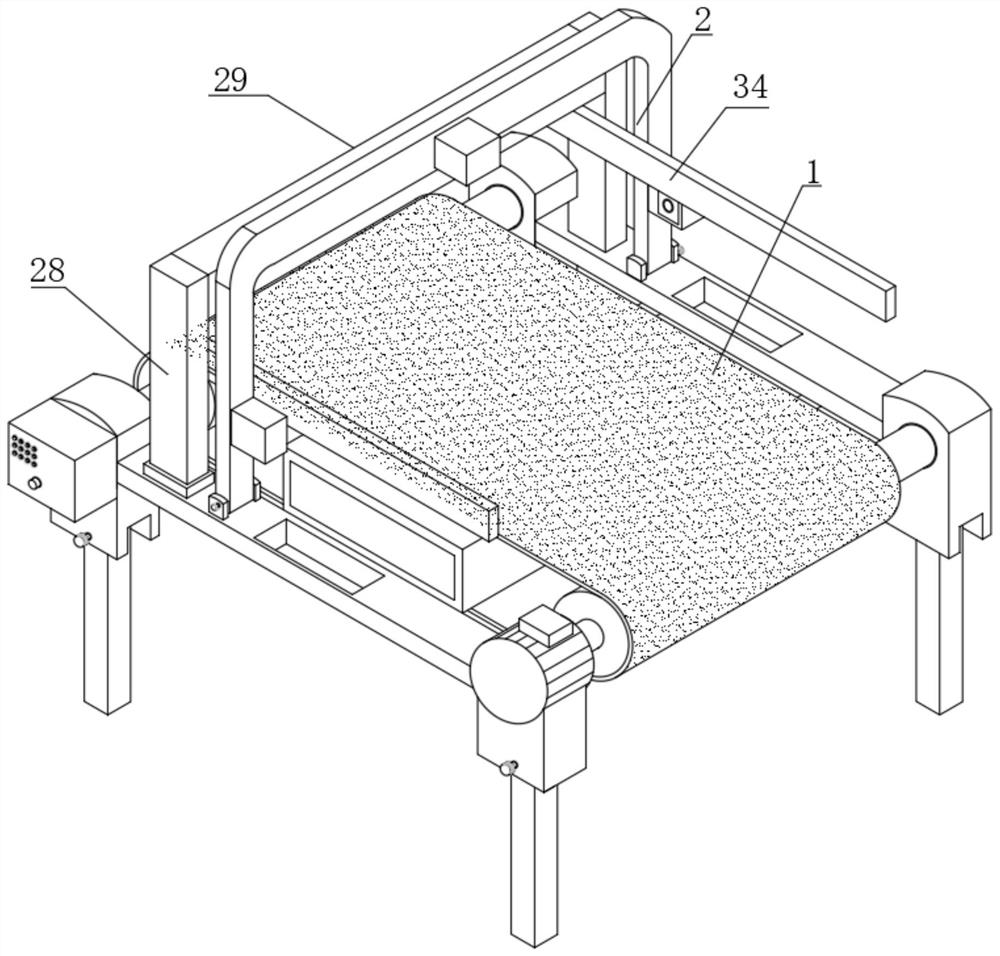

[0050] see Figure 2-4 , a goods circulation tracking supervision system based on the supply chain, the conveying mechanism 1 includes a supporting component 11, the upper end of one supporting component 11 is fixedly connected with a servo motor 12, the output end of the servo motor 12 is connected with one end of the conveying roller 13, and The servo motor 12 is electrically connected to the main controller 14, and the servo motor 12 and the main controller 14 are respectively electrically connected to the storage battery 18 to convey that the other end of the roller 13 is movably connected to one of the supporting components 11 opposite to the supporting component 11 at the lower end of the servo motor 12, One end of the transmission belt 16 is placed on the outside of the transmission drum 13, and the other end is placed on the outside of the transmission roller 15. The two sides of the transmission roller 15 are respectively movably connected with the opposite support ass...

Embodiment 3

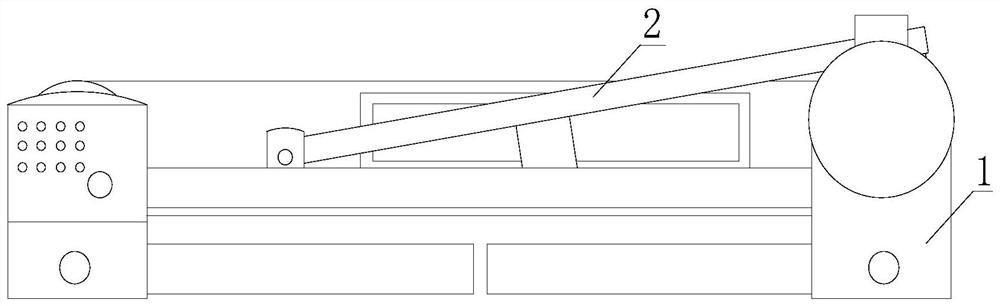

[0052] see Figure 5 , a goods circulation tracking supervision system based on the supply chain, the code scanning mechanism 2 includes an adjustment assembly 21, the two ends of the support frame 22 are movably connected with the adjustment assembly 21, and the first barcode scanning camera 23 is installed on one side of the support frame 22, And the support frame 22 opposite to support frame 22 is equipped with the 3rd bar code scanning camera 25, the second bar code scanning camera 24 is installed on the upper end middle part side of support frame 22, the first bar code scanning camera 23, the second bar code scanning camera 24 and The third barcode scanning camera 25 is electrically connected to the main controller 14 respectively, the first barcode scanning camera 23, the second barcode scanning camera 24 and the third barcode scanning camera 25 are respectively electrically connected to the storage battery 18, before the conveyor belt 16 transports the goods, Simply loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com