Oil level detection method and system

An oil level detection and oil level technology, applied in image data processing, instruments, calculations, etc., can solve problems such as increased compressor power consumption, severe friction of compressor bearings, high heat, etc., to increase safety and reduce consumption. , the effect of better safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

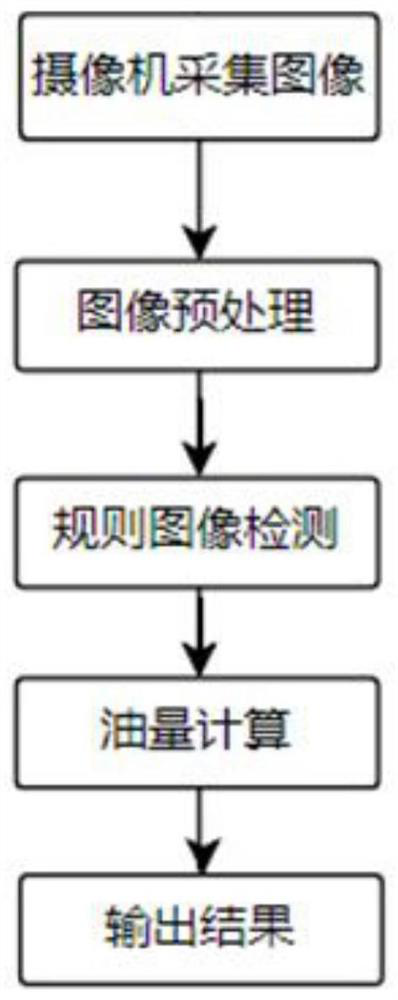

[0053] The first embodiment, such as figure 1 As shown, a computer vision-based oil level detection method includes the following steps:

[0054] S1, collecting the image of the oil level observation port;

[0055] S2, image preprocessing, select the area of interest to mark the oil level transparent area, reduce the noise edge of the image, and obtain the edge contour of the observation port and the oil level surface;

[0056] S3, regular image detection, setting the radius range of the oil level observation port, after filtering out invalid data, obtaining the radius and center coordinates of the circle where the oil level observation port is located;

[0057] Draw the oil level line, calculate the slope of the line where the oil level line is located, and calculate the intersection of the line and the circle;

[0058] S4, calculating and converting the distance from the center of the circle to the straight line into a percentage of oil volume.

no. 2 example

[0059] In the second embodiment, the present invention provides a computer vision-based oil level detection method, comprising the following steps:

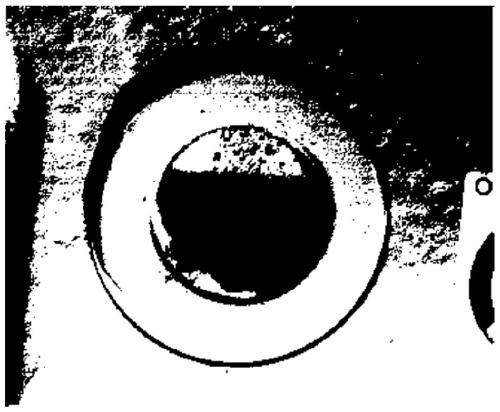

[0060] S1, reference figure 2 As shown, the image of the oil level observation port is collected;

[0061] Optionally, images can be captured by industrial cameras;

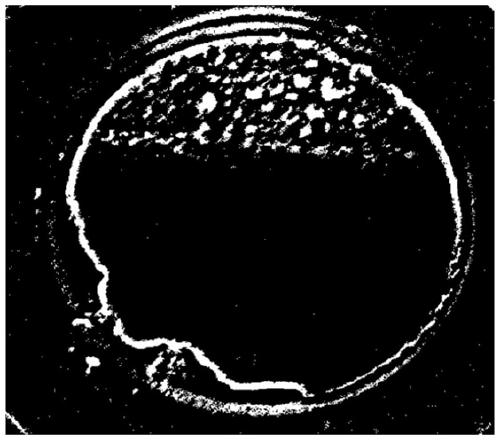

[0062] S2, ref. image 3 As shown in the image preprocessing, the region of interest is selected to mark the oil level transparent region. The region of interest is the region in the image with the same shape as the oil level observation port. First, bilateral filtering is used to remove image noise edges, and then adaptive image The binarized image processing obtains the edge contour of the observation port and the oil level surface.

[0063] S3, ref. Figure 4 As shown, regular image detection, according to the Hough circle fitting core algorithm, find out the circle and the center of the oil level observation port in the preprocessed image. At the same time,...

no. 3 example

[0078] For the third embodiment, refer to Image 6 As shown, a computer vision-based oil level detection system includes:

[0079] a light source, which is annular, and which is used to illuminate the oil level sight glass;

[0080] Optionally, the light source is provided with a light source controller;

[0081] a camera unit, which is used to acquire the image of the oil level observation port;

[0082] A server, which is used to obtain the percentage of oil quantity according to the image of the oil level sight glass and the oil level calculation rules;

[0083] The server can adopt a computer with image processing function;

[0084] Among them, the oil level calculation rules include:

[0085] Select the area of interest to mark the oil level transparent area, reduce the noise edge of the image, and obtain the edge contour of the observation port and the oil level surface;

[0086] Set the radius range of the oil level observation port, filter invalid data, obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com