Full-automatic laser paint stripping and identifying all-in-one machine

A laser peeling, fully automatic technology, applied in conveyors, conveyor objects, rotary conveyors, etc., can solve the problems of smaller and more precise component structure, difficulty in production and testing, and component alignment and grasping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

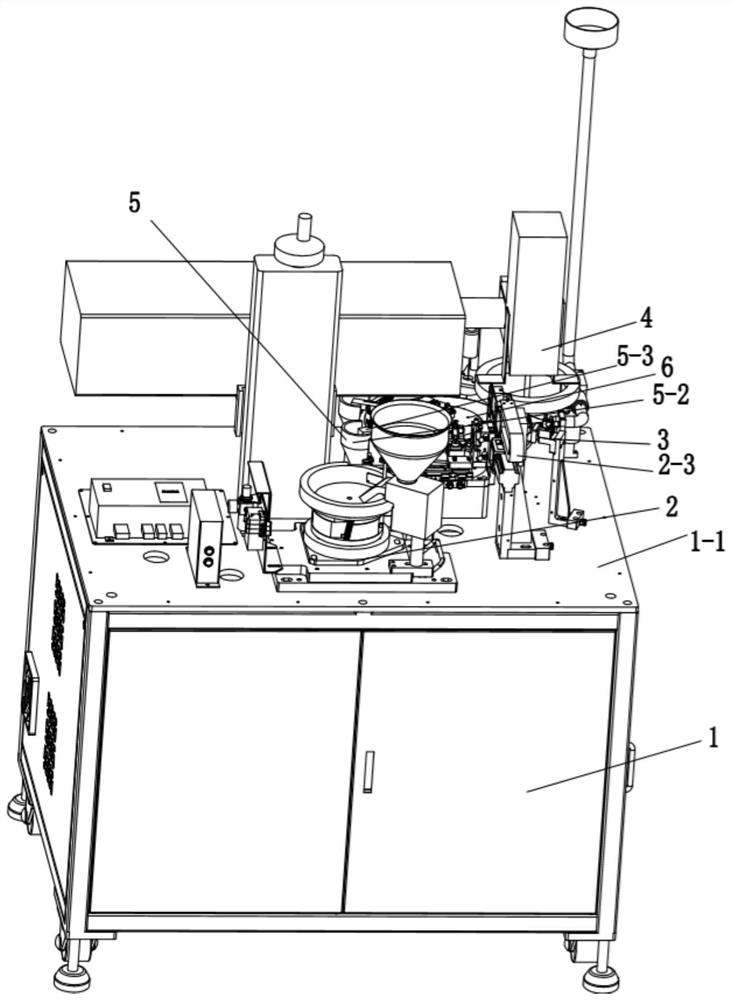

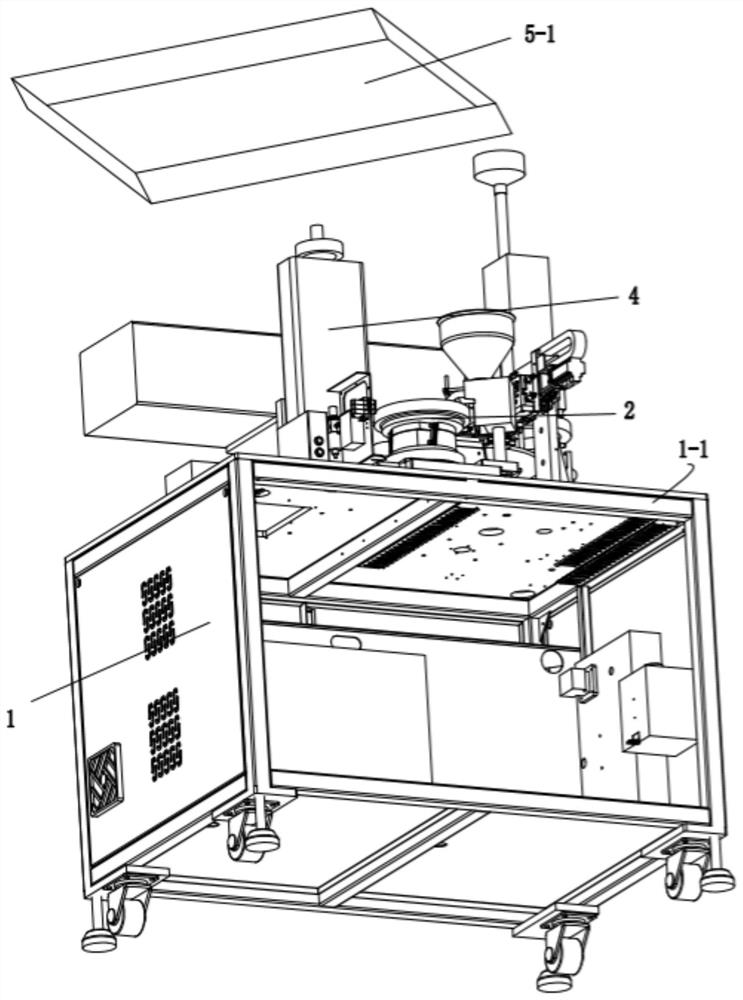

[0048] see Figure 1-18 , the present embodiment provides a fully automatic laser paint stripping recognition machine, comprising a frame 1, the following components are arranged on the table panel 1-1 of the frame 1:

[0049] A vibrating plate feeding assembly 2 for loading and transporting components;

[0050] The separation component 3 that transfers the vibrating plate feeding component 2 and takes out the stacked components;

[0051] Paint stripping component 4 for stripping paint on the surface of the components after taking materials;

[0052] A receiving assembly 5 for collecting the components after the paint stripping assembly 4 is completed;

[0053] And a rotating assembly 6 for transferring components between the reclaiming station, the paint stripping station and the receiving station;

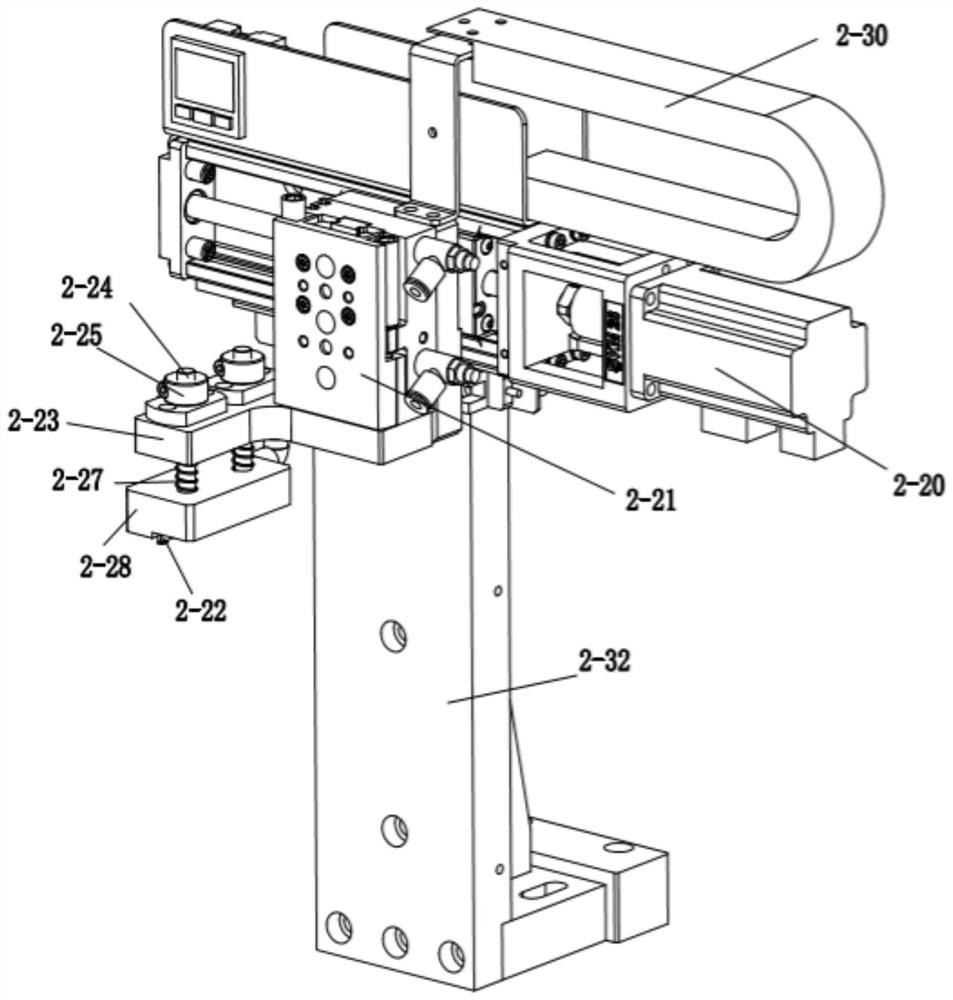

[0054] Wherein, the separation assembly 3 includes a dynamic separation assembly 3-1, and the dynamic separation assembly 3-1 includes a first fixed frame 3-2, a first cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com