Auxiliary device for making foam model for automobile mould processing

A foam model, automobile mold technology, applied in workpiece clamping devices, manufacturing tools, cleaning methods and utensils, etc., can solve the problem of automobile foam model processing, can not meet the needs of difficult foam model processing, and foam debris is easy to adhere to. Problems such as the outer side of the foam model to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

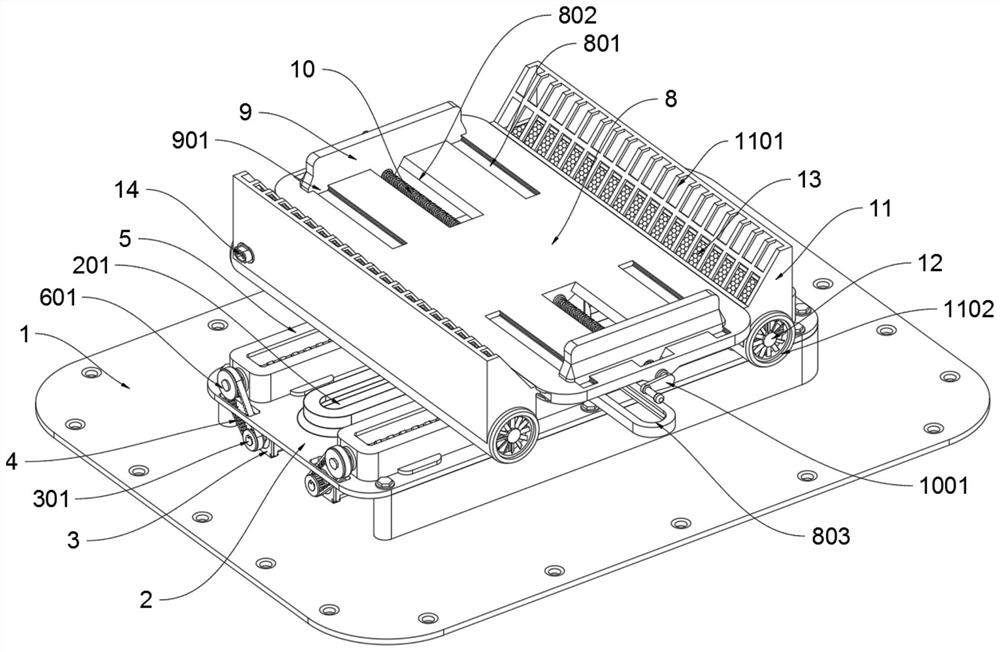

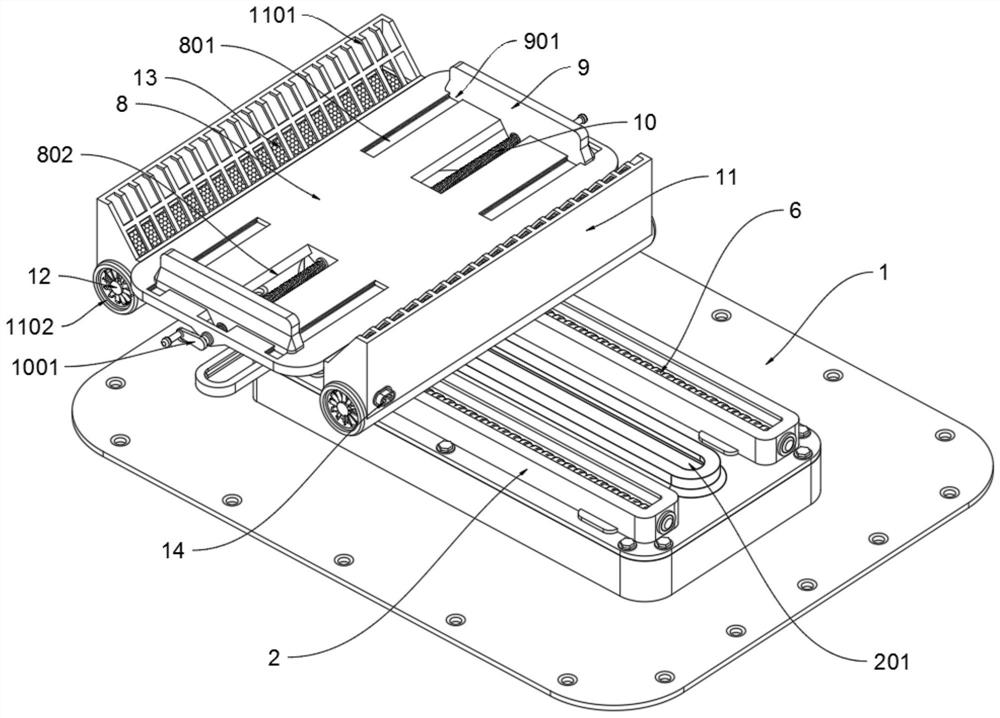

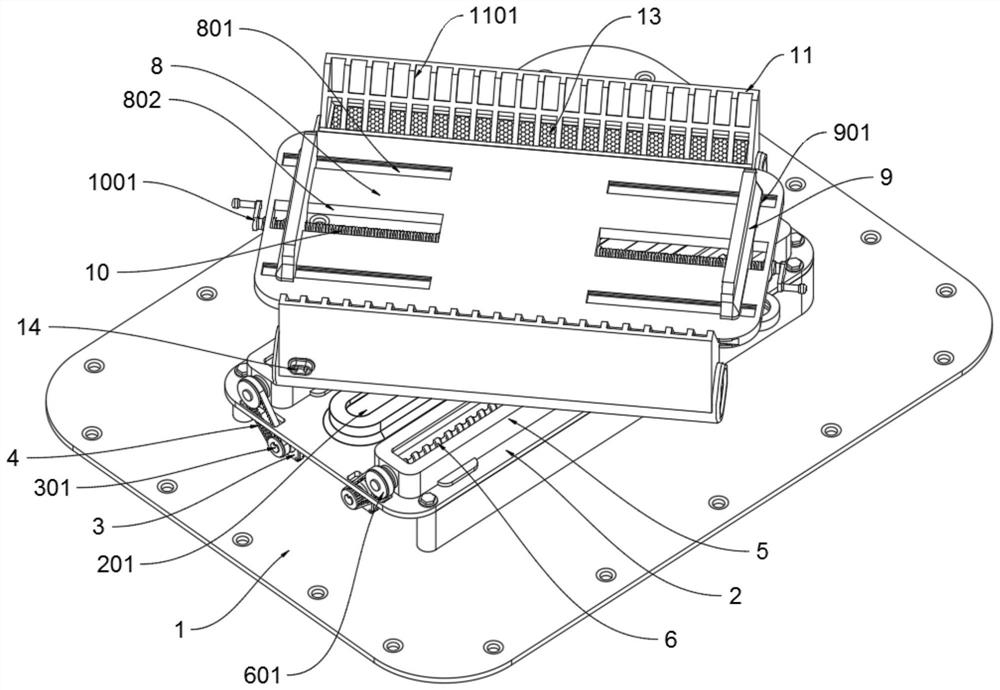

[0034] as attached figure 1 to attach Figure 10 Shown:

[0035]The present invention provides an auxiliary device for making a foam model for automobile mold processing, which includes a receiving plate 2, a driving motor 3, a driving assembly groove 5, a driving block 7, a placing plate 8, a clamping plate 9, a screw 10 and a debris collection case 11 The receiving plate 2 is installed on the top of the base 1 through bolts, and the receiving plate 2 is a square plate-shaped structure; there are two driving motors 3, and the two driving motors 3 are respectively connected to the external control circuit through power lines; there are two driving assembly slots 5 , the two driving assembly grooves 5 are respectively installed at the front and rear ends of the top of the receiving plate 2, and the screw rod 6 is located inside the driving assembly groove 5; Drive pulley 301; Screw mandrel 6 left ends are equipped with a driven pulley 601, and drive pulley 301 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com