Jig for automatically locking and assembling screws in car headlights

An internal screw and automatic locking technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, metal processing, etc., can solve the problems of labor-consuming, secondary rework, long assembly time, etc., to prevent locking failure or missing lock, prevent Improper alignment and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

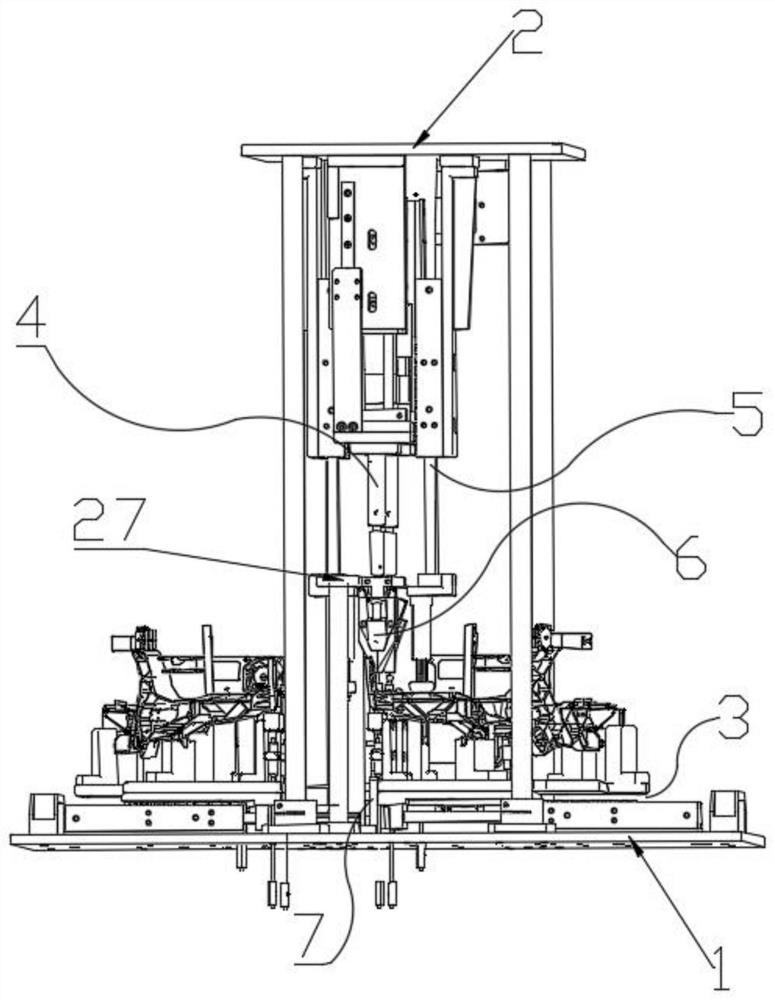

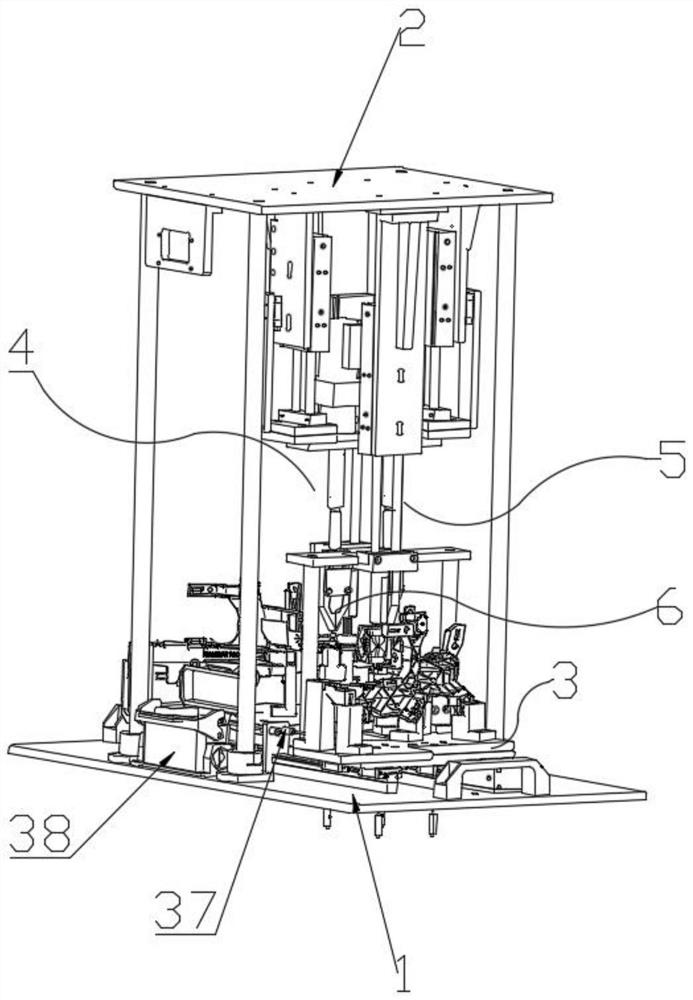

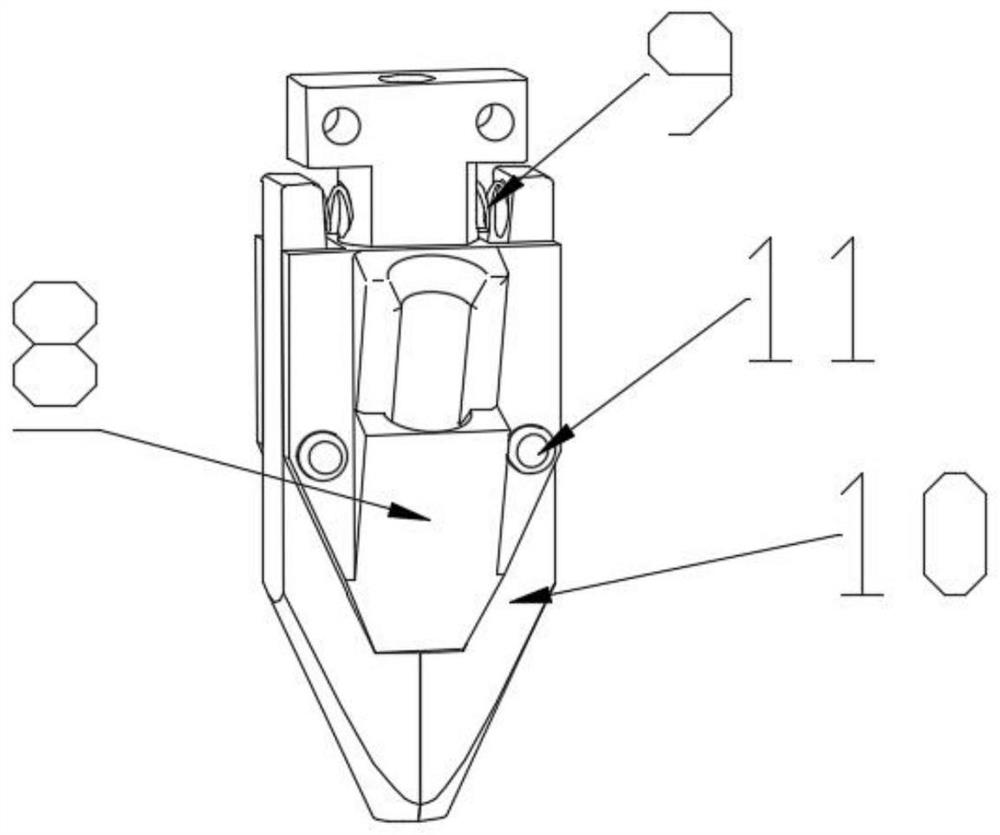

[0035] Example: see Figure 1~3 , in the present invention, the jig for automatically locking and assembling the inner screw of the automobile headlight includes a support base plate 1, the upper end of the support base plate 1 is provided with an upper support frame 2 and a lower support frame 27, and the support base plate 1, the upper support frame 2 and the lower support frame Frame 27 is all used to support this device, and lower support frame 27 both sides are provided with feeding mechanism 3, and feeding mechanism 3 can support the parts of automobile headlight, and parts are moved to the olecranon beak holding structure 6 lower ends, and parts are carried out. Locking, the lower end of the upper support frame 2 is provided with a locking structure 4, the locking structure 4 is driven by the cylinder to do vertical up and down movement and rotational movement, and is used to lock the screw to the lamp parts, the two sides of the locking structure 4 A height control mec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap