An automatic transmission case oil seal assembly device and method

An automatic transmission and assembly method technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of difficulty in ensuring the depth of transmission oil seals, poor assembly retention of high-quality oil seals, inconsistent oil seals and depths, etc. Flexible use and avoid repeated installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

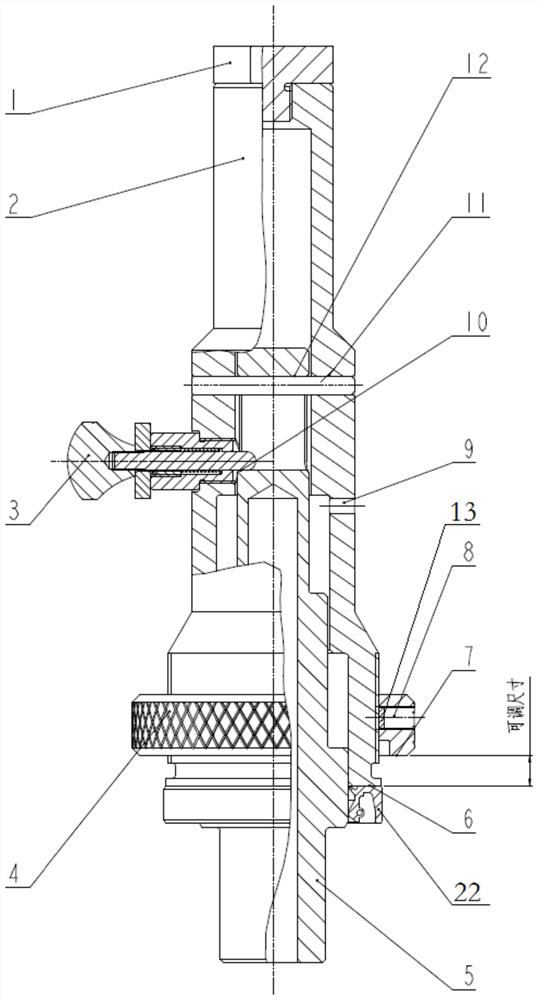

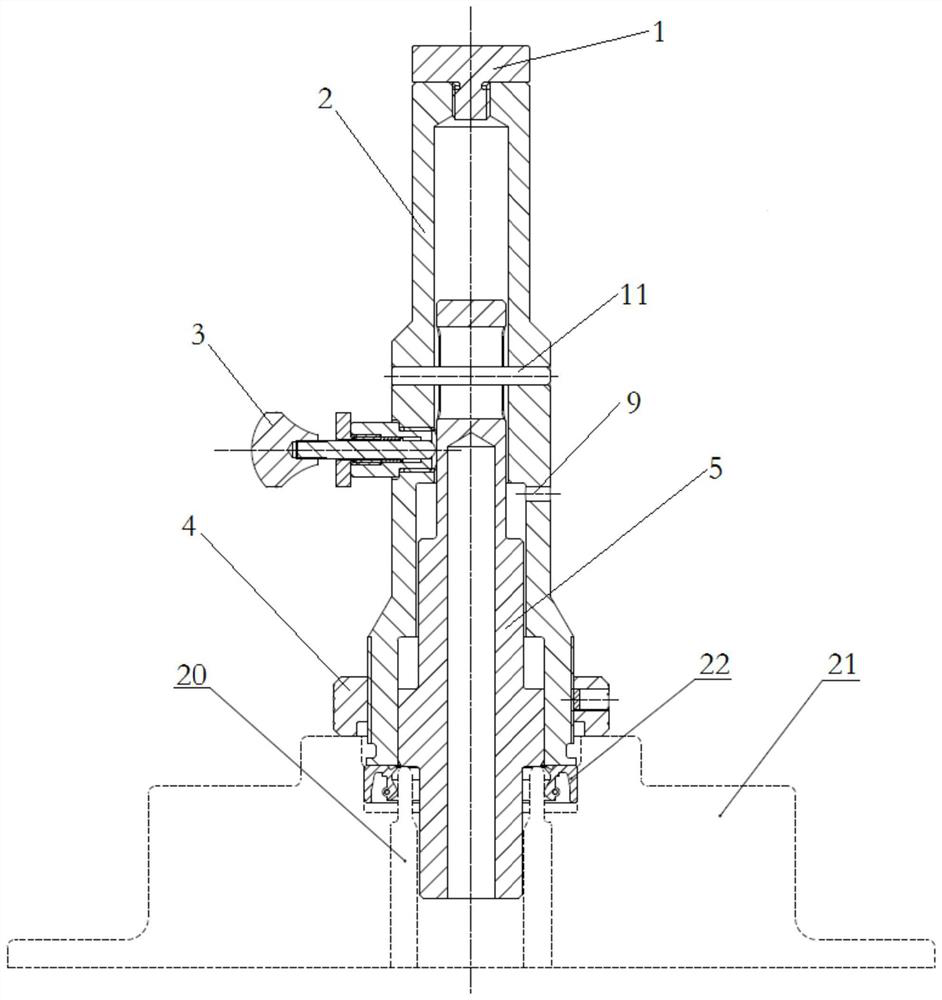

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

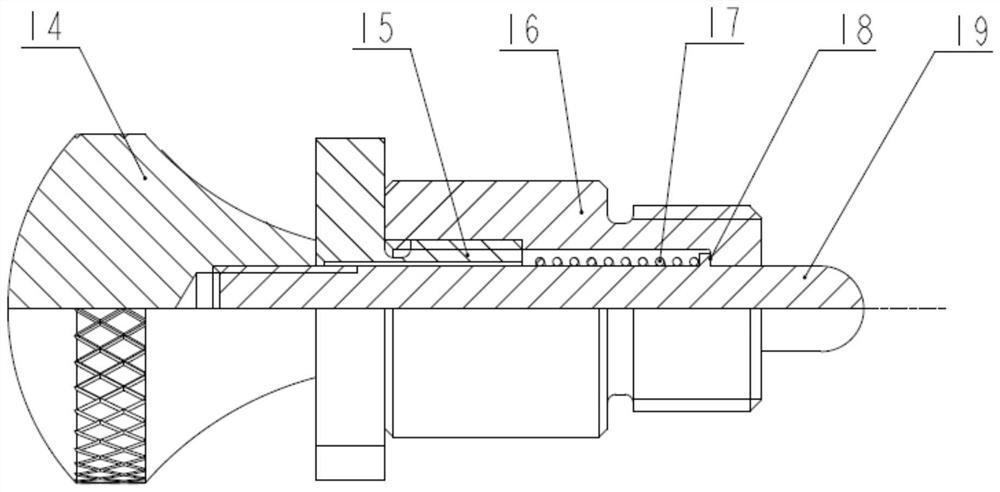

[0033] Such as figure 1 As shown, the automatic transmission casing oil seal assembly device of the present invention includes a cap, a sleeve 2, a limit screw 3, an adjusting nut 4, a guide shaft 5 and a positioning pin 11.

[0034] The circumference of the bottom end of the sleeve 2 is provided with threads, and the adjusting nut 4 is nested on the sleeve 2 through the threads, and the adjusting nut 4 can be rotated to change the distance from the bottom end of the sleeve 2; Extending into the sleeve 2, the gap between the guide shaft 5 and the sleeve 2 is set, the diameter of the guide shaft 5 near the bottom is larger than that of the rest of the guide shaft 5, forming a stepped shaft; the oil seal 22 is nested on the largest diameter part of the guide shaft 5, The bottom end of the sleeve 2 is the limiting end face of the oil seal 22, and the top end of the oil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com