Barcode attaching rotating and conveying mechanism for electronic product automatic packaging and barcode conveying method

A technology for pasting barcodes and electronic products, which is applied in the direction of rotary conveyors, conveyors, packaging, etc., can solve the problems of unstable rotary transportation of packaging boxes, and achieve the effect of improving the accuracy and fluency of rotary transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

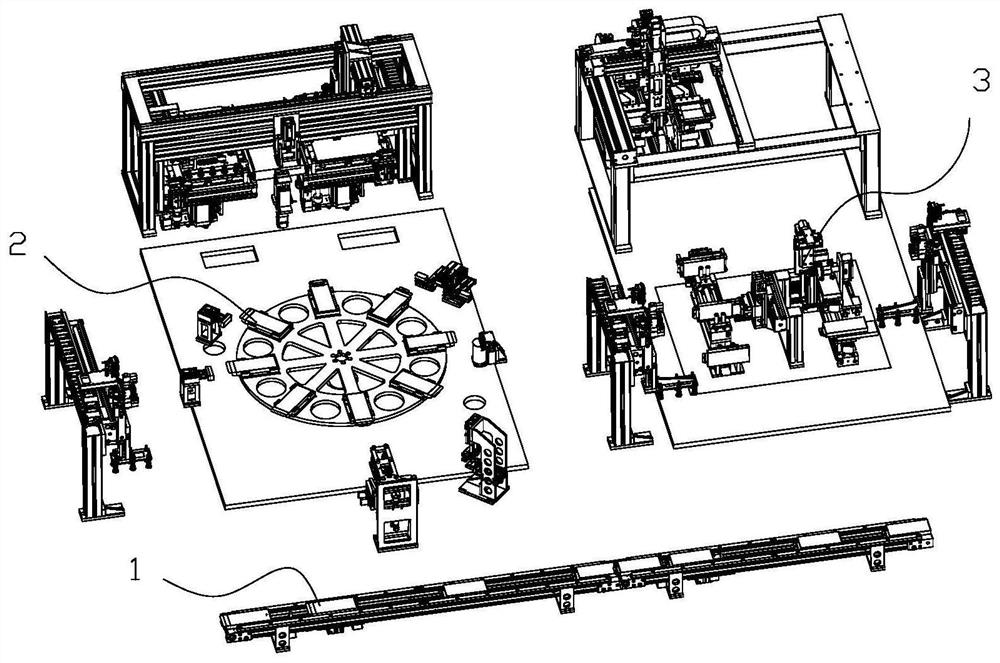

[0035] Such as figure 1 As shown, an electronic product boxing automation equipment, the equipment includes a frame and a conveying device 1 on it, a packing box folding labeling device 2 and a packing box barcode sticking device 3; the conveying device 1 is arranged horizontally, and the conveying device 1 is located at The packaging box is folded to the front side of the labeling device 2 and the packaging box barcode application device 3. The conveying device 1 includes a conveying motor and a conveyor belt assembly. The rotating shaft of the conveying motor is connected to the conveyor belt assembly, and the conveyor belt assembly drives the packaging box to be transported. The device 2 is used to fold and seal the opening of the packaging box, and the packaging box sticking barcode device 3 is used to stick the barcode on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com