Wharf shipment belt conveyor system for large water level difference

A belt conveyor, water level difference technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of inability to meet production needs, and achieve the effect of light weight, simple structure, and prevention of material scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A dock loading belt conveyor system for large water level difference provided by the present invention will be further described in detail and completely below in conjunction with the embodiments. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

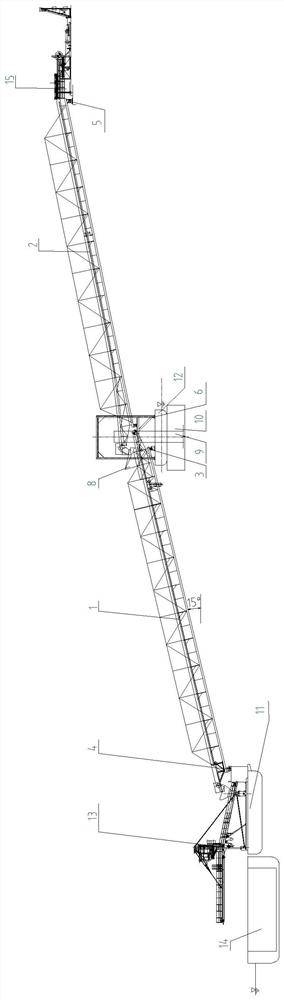

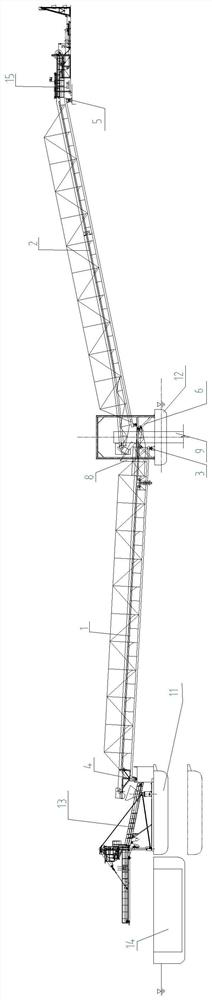

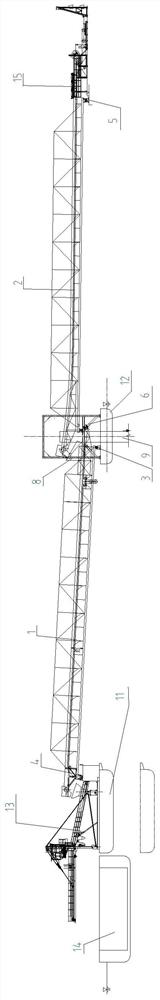

[0028] A dock loading belt conveyor system for large water level difference, such as Figure 1 to Figure 4 As shown, it includes a steel approach bridge device, a first floating dock 11 , a second floating dock 12 and a ship loading device 13 . The distance between the first floating dock 11 and the shore feeding device 15 is greater than the distance between the second floating dock 12 and the shore feeding device 15, and the first floating dock 11 is always located on the water surface, specifically, on the water surface close to the cargo ship 14 . The second pontoon 12 is located on the river bed on the bank. As can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com