A panel structure prefabricated house using corner connections for force transmission and energy dissipation

A corner connection and prefabricated technology, applied in the direction of building components, structural elements, building structures, etc., can solve the problem of poor thermal insulation performance of prefabricated house nodes, ineffective energy dissipation and shock absorption measures, and uneconomical prefabricated house structure. and other problems, to achieve the effect of significant energy dissipation capacity, clear shock absorption mechanism, and avoidance of component cross-sectional size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The preferred embodiments of the present invention will be further described in detail below.

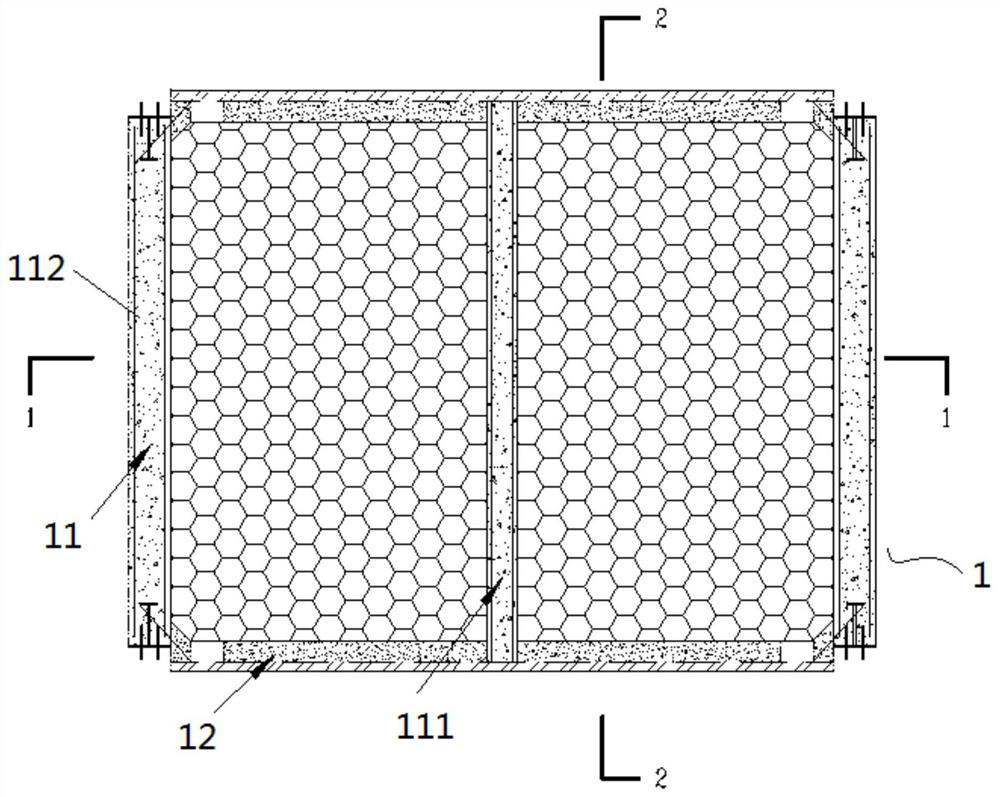

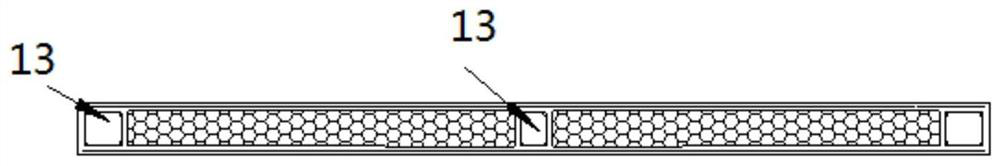

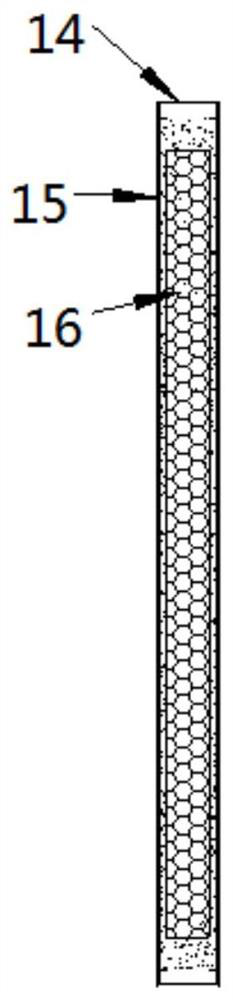

[0065] Such as Figure 1 to Figure 16 As shown, a prefabricated house with panel structures that utilizes corner connections for force transmission and energy dissipation includes wall panels 1 and floor panels 2, and the upper and lower wall panels 9 and floor panels 2 are connected by cover panels 3 at the corners. An energy dissipation and shock absorbing device 4 is provided between the corner of the wallboard 1 and the corner of the floor 2; the energy dissipation and shock absorbing device 4 passes through the upper wallboard 8, the floor 2 and the lower wallboard through a long screw 5 9; Energy dissipation and shock absorption through the corners. The wallboard 1 is a sandwich insulation board, and the internal stress frame of the sandwich insulation board includes a reinforced concrete column 11 and a channel steel concrete composite beam 12; the floor 2 is a sandwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com