Fuel oil moisture on-line monitoring device

A technology for monitoring devices and moisture, which is applied to measuring devices, analyzing materials, and analyzing materials by electromagnetic means, etc., can solve the problems of cumbersome device structure, complicated monitoring methods, and high cost, and achieve simple structure, rapid moisture content monitoring, and low price. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

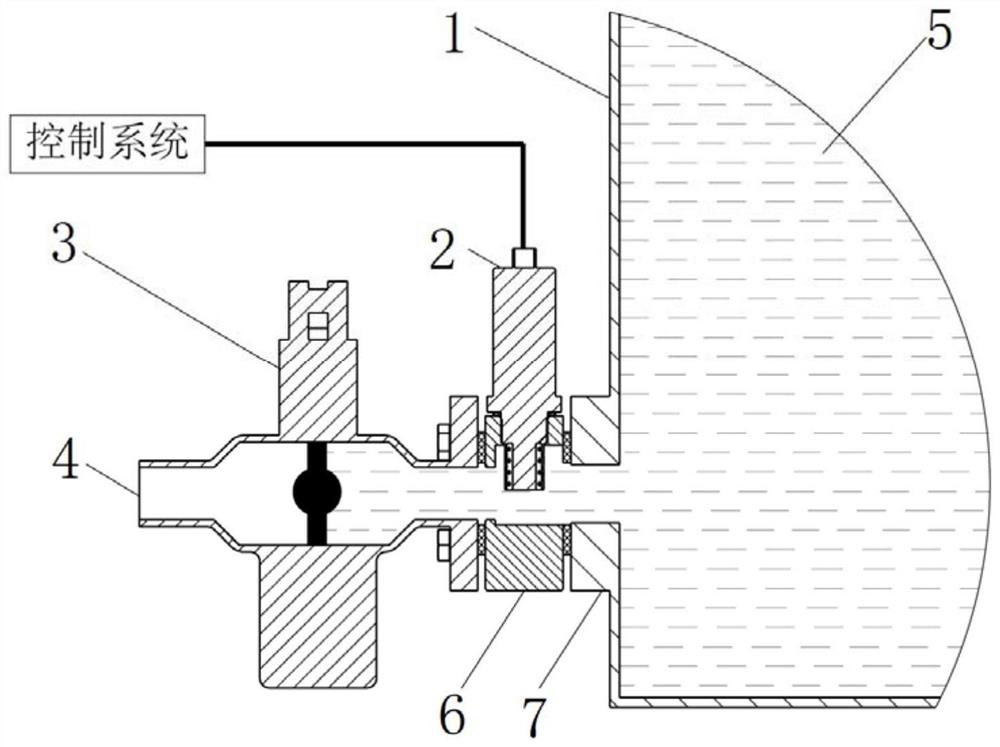

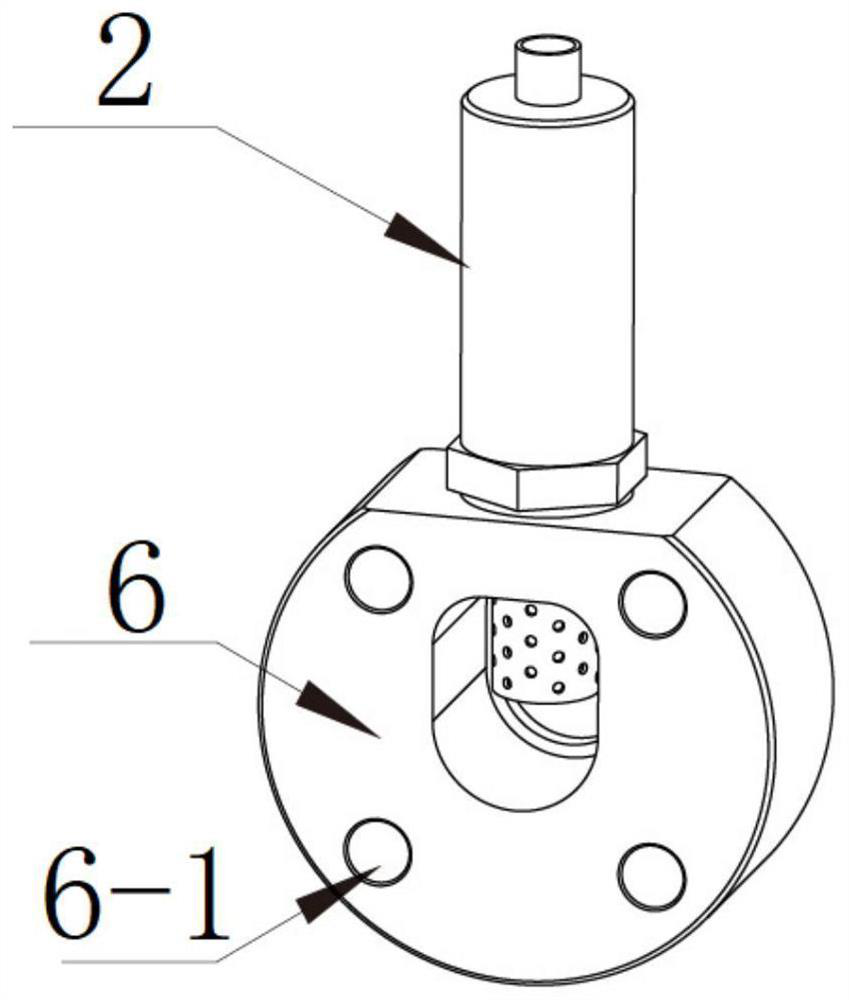

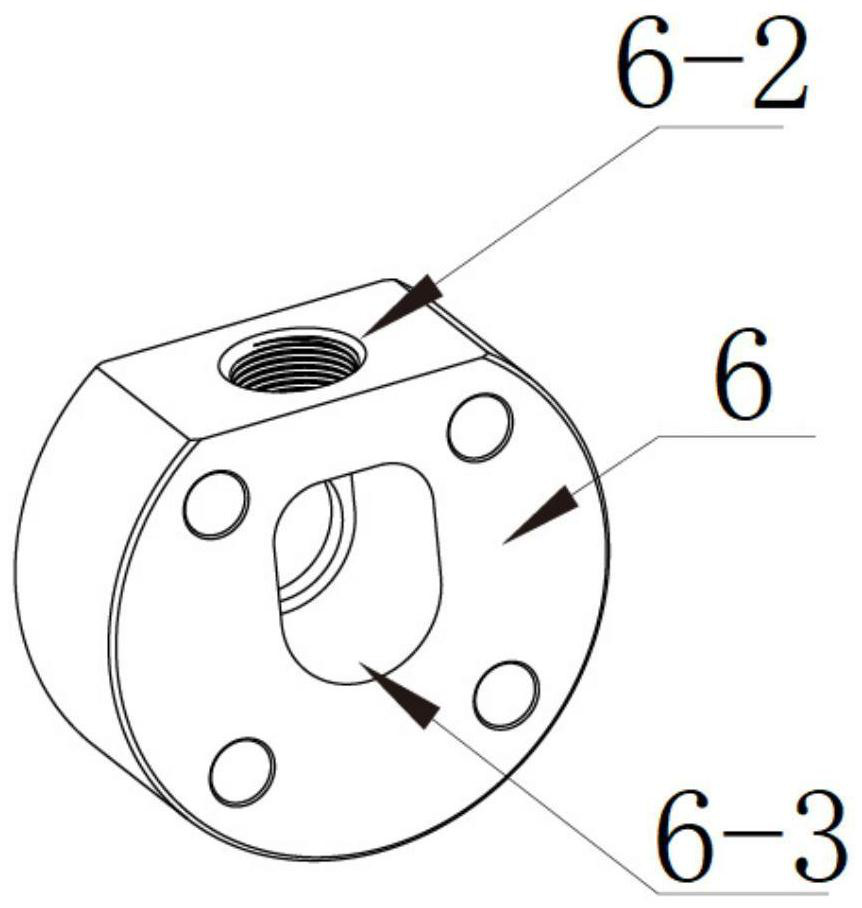

[0021] The fuel moisture online monitoring device of the present invention, such as figure 1 As shown, it includes a moisture sensor 2, a sensor mounting seat 6 and a control system; the existing oil conservator 1 installs a sampling ball valve 3 at the flange port 7 of the oil conservator, and the present invention installs the sensor mounting seat 6 between the two, The moisture sensor 2 is installed on the sensor mount 6 again.

[0022] The use of this device does not require additional construction or auxiliary pipelines on the fuel system (oil conservator). Just remove the sampling ball valve 3 of the oil conservator 1, install the sensor mounting seat 6 on the flange port 7 of the oil conservator, and then install the sampling ball valve 3 on the sensor mounting seat 6. It not only solves the difficulty and cumbersome installation of sensors in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com