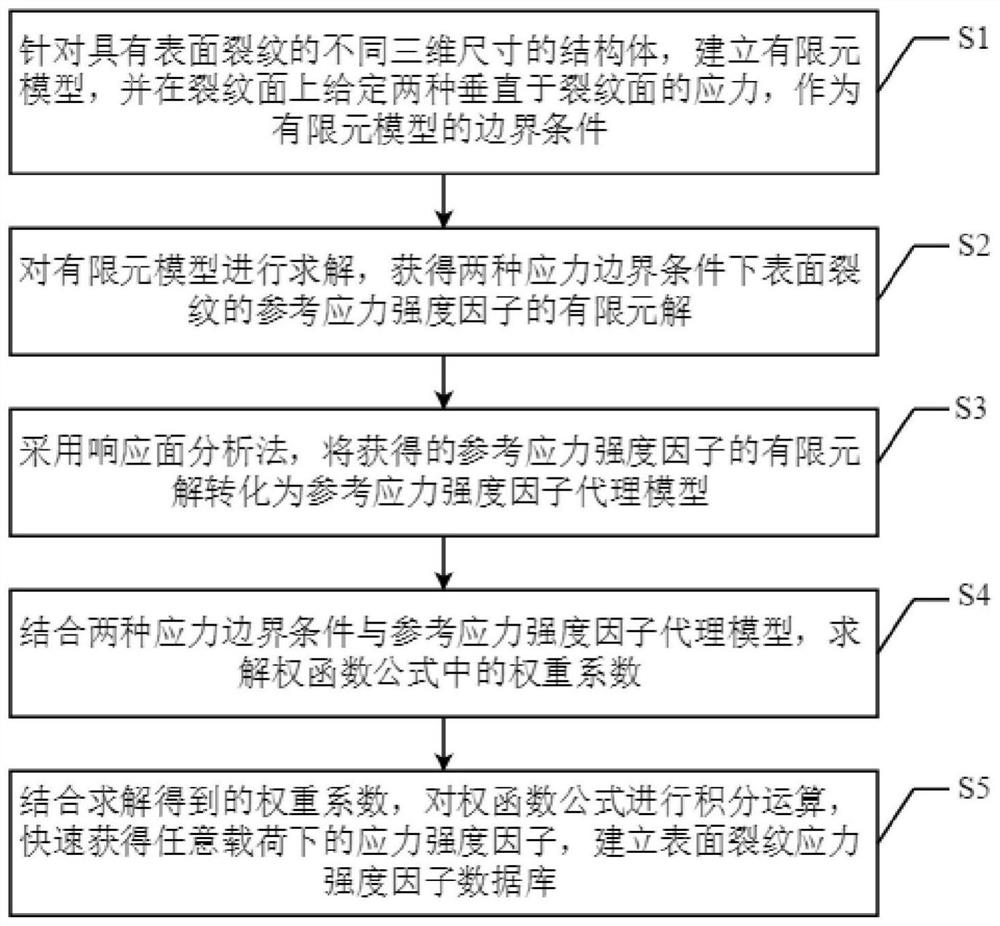

Weight function-based surface crack stress intensity factor database establishment method

A technology of stress intensity factor and surface cracks, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as efficiency impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

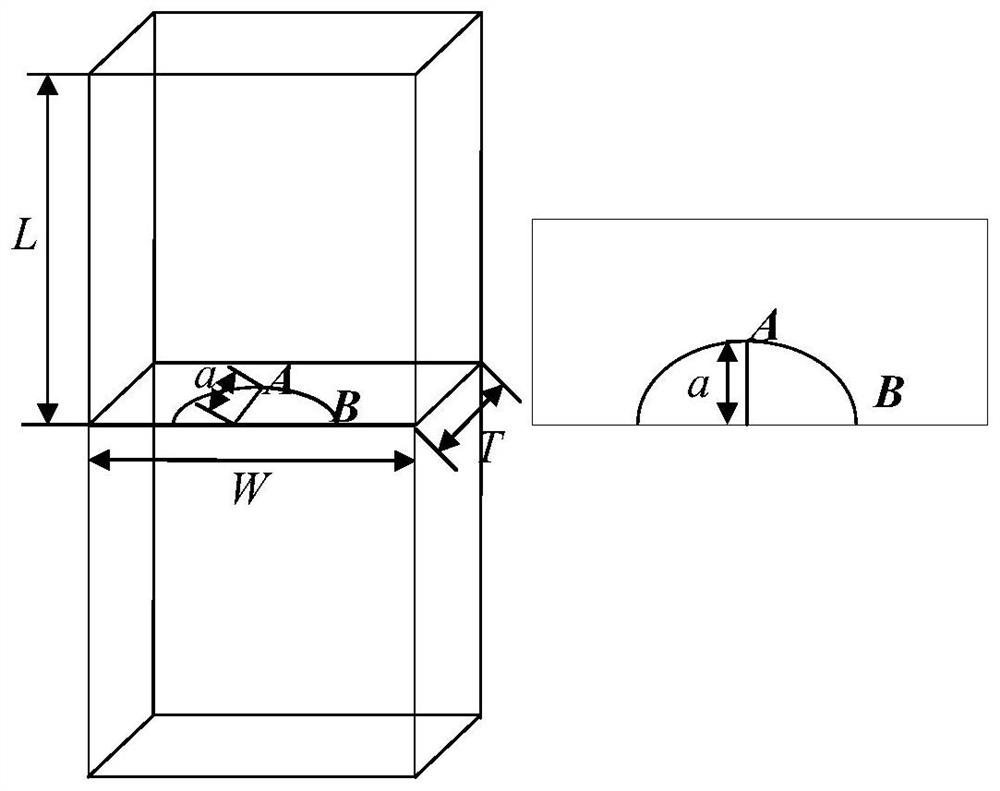

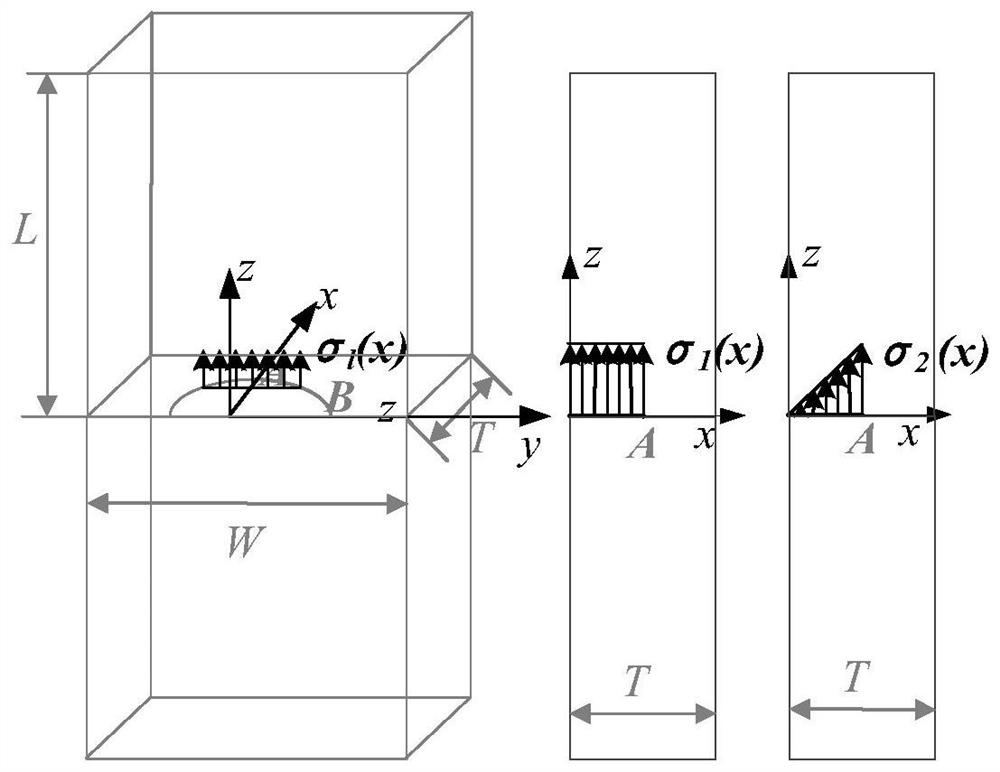

[0065] In the specific implementation, when performing step S1 in the method for establishing the above-mentioned surface crack stress intensity factor database provided by the present invention, a finite element model is established for structures with different three-dimensional dimensions with surface cracks, and two values are given on the crack surface. When a stress perpendicular to the crack surface is used as the boundary condition of the finite element model, it can be realized in the following ways:

[0066] The four parameters involved in the finite element model are the circular crack radius a, the thickness of the structure T, the width W of the structure, and the half-height L of the structure. These four parameters are simplified into three parameters after being dimensionless and The value ranges of these three parameters are:

[0067]

[0068] and According to the range of formula (1), the finite element model of the structure containing surface cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com