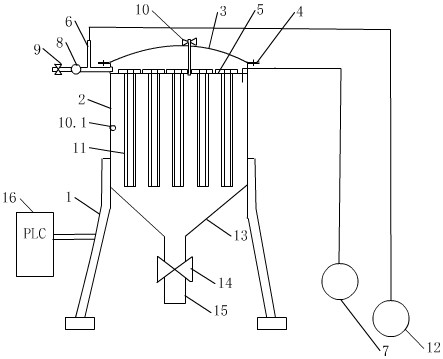

Method for carrying out sediment and water separation treatment by utilizing slurry separation device

A mud-water separation, separation and treatment technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of incomplete separation, slow separation of sediment and water, etc., and achieve good mud-water separation effect and large processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

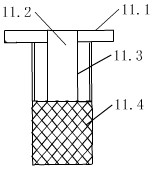

[0029] The filter tube of the separation device uses PPR tube or polypropylene tube, and the filter screen uses microporous fiber filter cloth.

[0030] Sediment and water separation method:

[0031] The mud-containing sewage in the mud pool is transported to the tank through the mud pump, and the mud water fills the tank. Under the pressure of the mud pump, the mud passes through the filter to attach the mud to the outside of the filter, and the clear water filtered through the filter passes through the pipe wall. The hole is discharged from the tube cavity into the space between the filter tube installation hole plate and the upper cover of the head, and is discharged through the clean water pipe and the clean water control valve to be used as clean water. When the filter tube is used for a period of time, there will be mud on the filter net Adhesion and retention, at this time, turn on the backwash pump, drop the sediment retained in the filter to the conical cavity through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com