Cutting device for stainless steel filter screen processing

A technology of cutting device and filter screen, which is applied in the direction of metal processing equipment, etc., can solve the problems of single cutting direction of the cutter, inability to cut the filter screen, inconvenient clamping and fixing of the filter screen, etc., and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

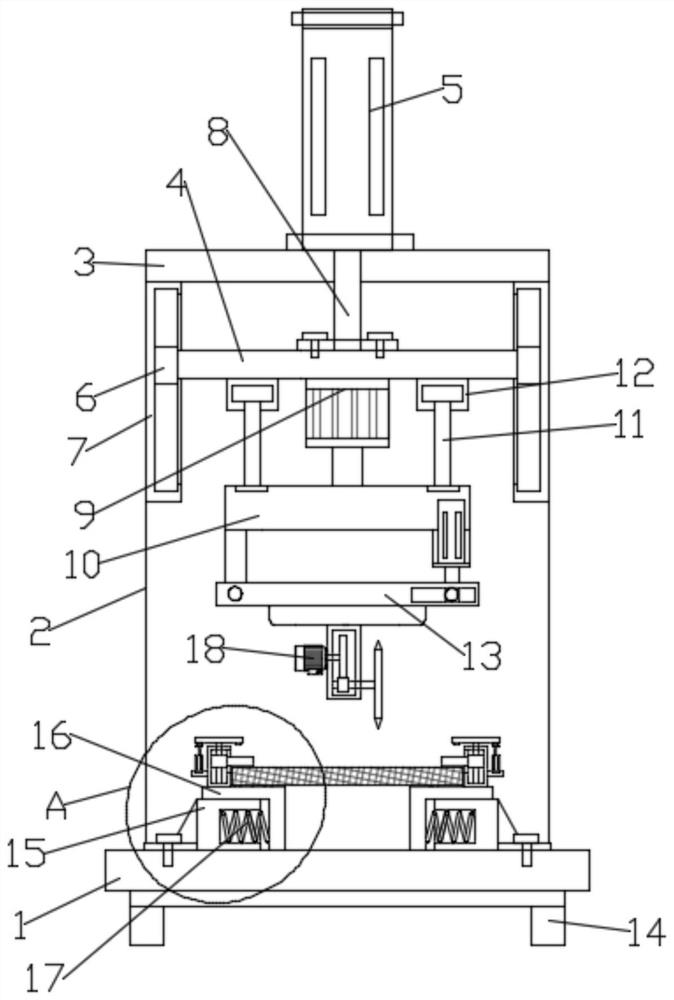

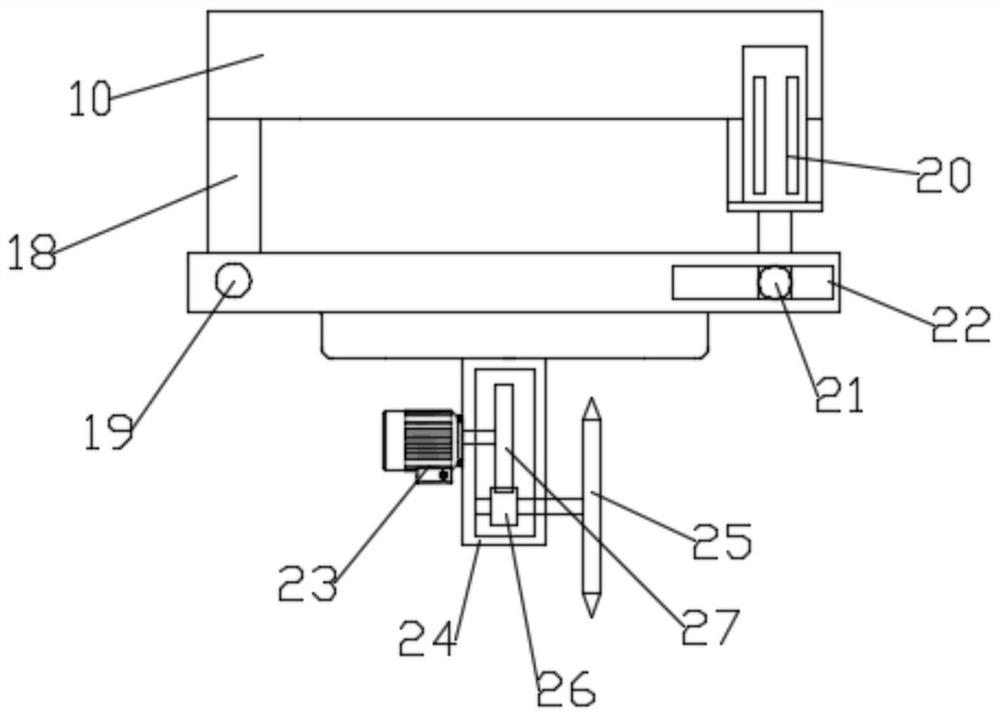

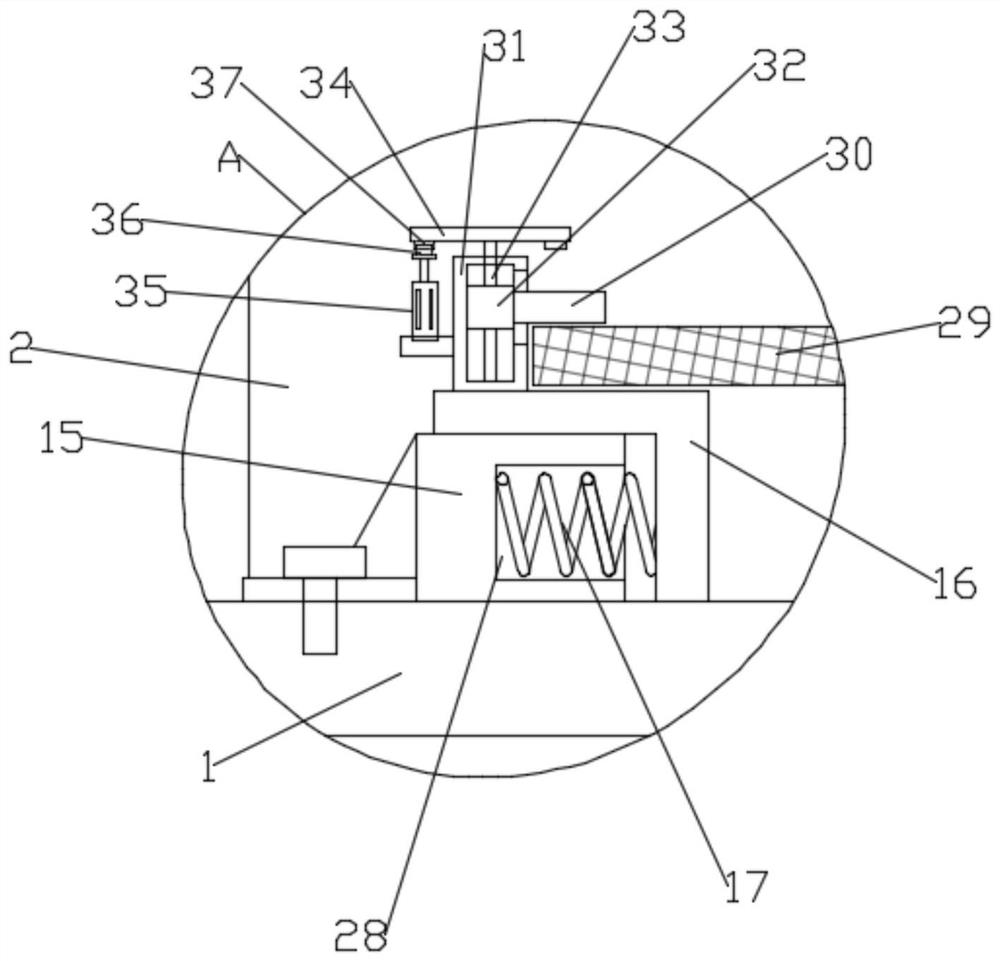

[0026] Such as figure 1 As shown, in the embodiment provided by the present invention, a cutting device for stainless steel filter mesh processing includes a base 1, the four corners of the lower surface of the base 1 are provided with feet 14; the base 1 is provided with clips The clamping mechanism is used to clamp and fix the stainless steel filter screen 29; the upper surface of the rear side of the base 1 is also fixedly provided with a supporting backboard 2, and the top of the supporting backboard 2 is provided with a supporting top board 3, The support top plate 3 is provided with a hydraulic telescopic cylinder 5, and the telescopic end of the hydraulic telescopic cylinder 5 is linked with a piston rod 8, and the bottom end of the piston rod 8 is fixedly installed with a lifting beam 4, and a useful In order to adjust the first driving motor 9 of the horizontal rotation direction of the cutting assembly, the output shaft of the first driving motor 9 is equipped with a...

Embodiment 2

[0032] Such as figure 1 As shown, in the embodiment provided by the present invention, a cutting device for stainless steel filter mesh processing includes a base 1, the four corners of the lower surface of the base 1 are provided with feet 14; the base 1 is provided with clips The clamping mechanism is used to clamp and fix the stainless steel filter screen 29; the upper surface of the rear side of the base 1 is also fixedly provided with a supporting backboard 2, and the top of the supporting backboard 2 is provided with a supporting top board 3, The support top plate 3 is provided with a hydraulic telescopic cylinder 5, and the telescopic end of the hydraulic telescopic cylinder 5 is linked with a piston rod 8, and the bottom end of the piston rod 8 is fixedly installed with a lifting beam 4, and a useful In order to adjust the first driving motor 9 of the horizontal rotation direction of the cutting assembly, the output shaft of the first driving motor 9 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com