Multipurpose milling clamp

A fixture and bottom plate technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of reducing the production efficiency of the oil separator, high fixture manufacturing costs, high fixture management costs, etc., to achieve low fixture management costs, low production costs, The effect of reducing production cost and management cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

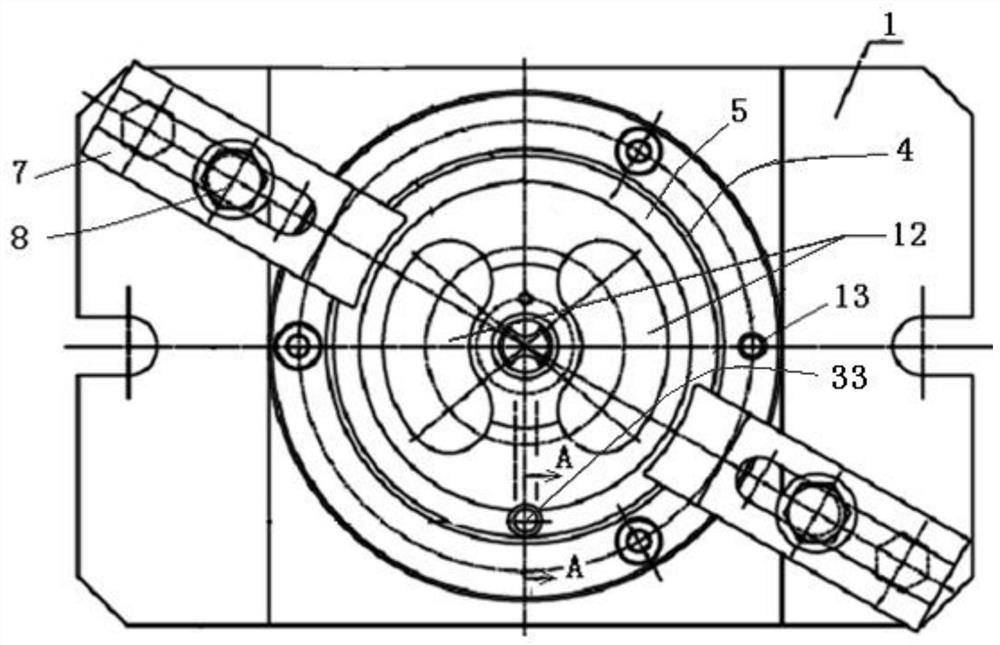

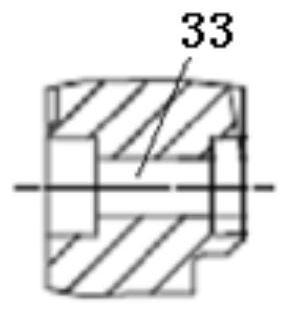

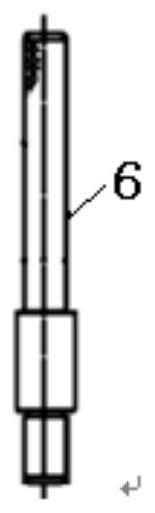

[0025] Example. Versatile milling fixture for machining such as Figure 7 to Figure 9 The oil separator of the piston pump of the quantitative motor series shown, the blank to be processed is in the shape of a disc, one side of the blank has a spherical surface 20 that bulges outward, the other side is a flat end surface 21, and the axis has a step center In the hole 22 , the outer side of the spherical surface 20 has a conical surface 27 connected to the peripheral surface, and the spherical surface 20 and the conical surface 27 are connected by a cylindrical surface 28 . It is necessary to machine the crescent hole 23, the groove 24 and the stepped hole 25 on the flat end surface 21, and machine eight small holes 26 on the spherical surface.

[0026] The structure of the multi-purpose milling fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com