Small concrete trial mixing system for laboratory

A technology for laboratory use and concrete, which is applied in batching and batching instruments, batching weighing instruments, clay preparation devices, etc. It can solve the problems of low efficiency of concrete raw material allocation, concrete raw materials affecting test quality, and unsatisfactory mixing efficiency. Achieve the effect of improving configuration accuracy, functional utility, and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

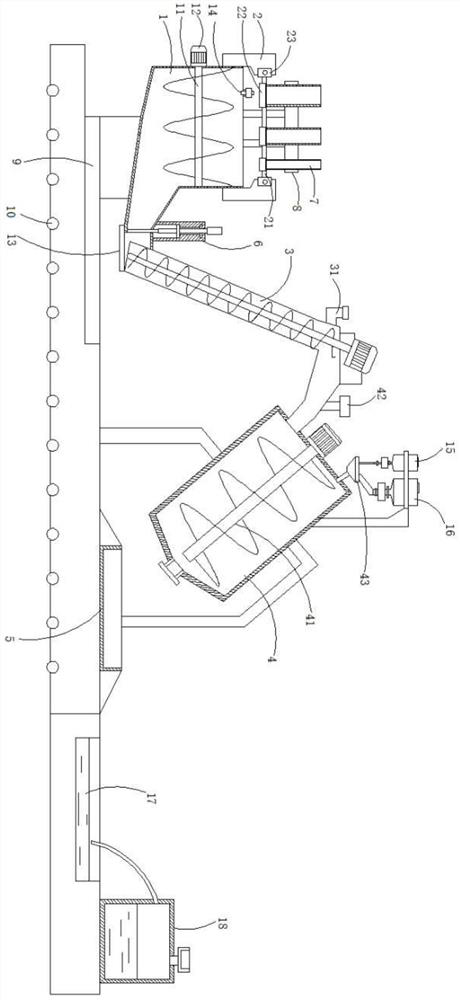

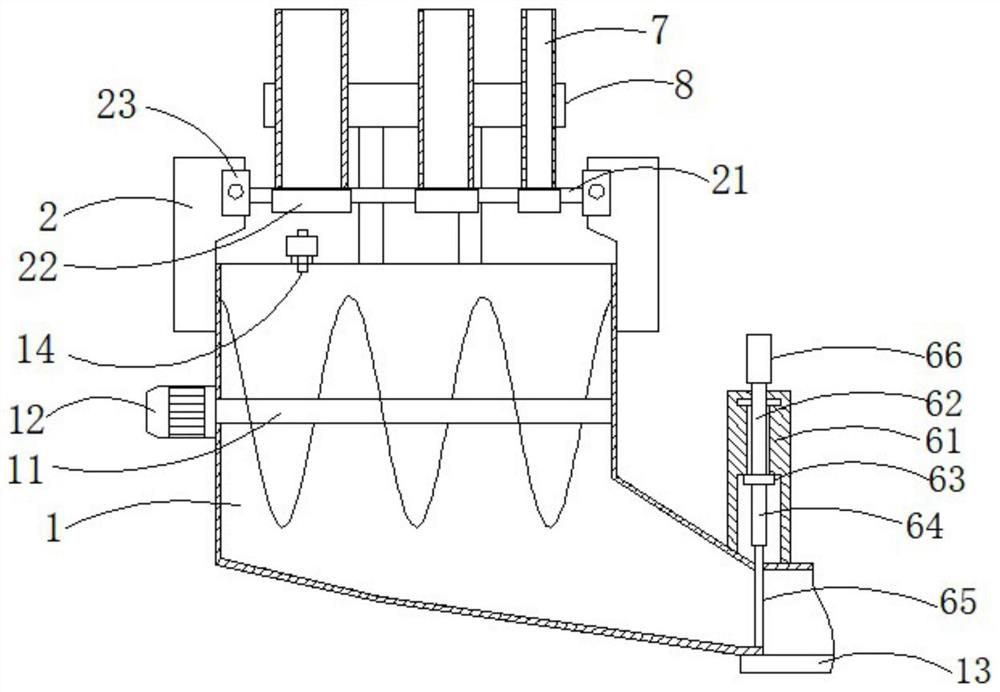

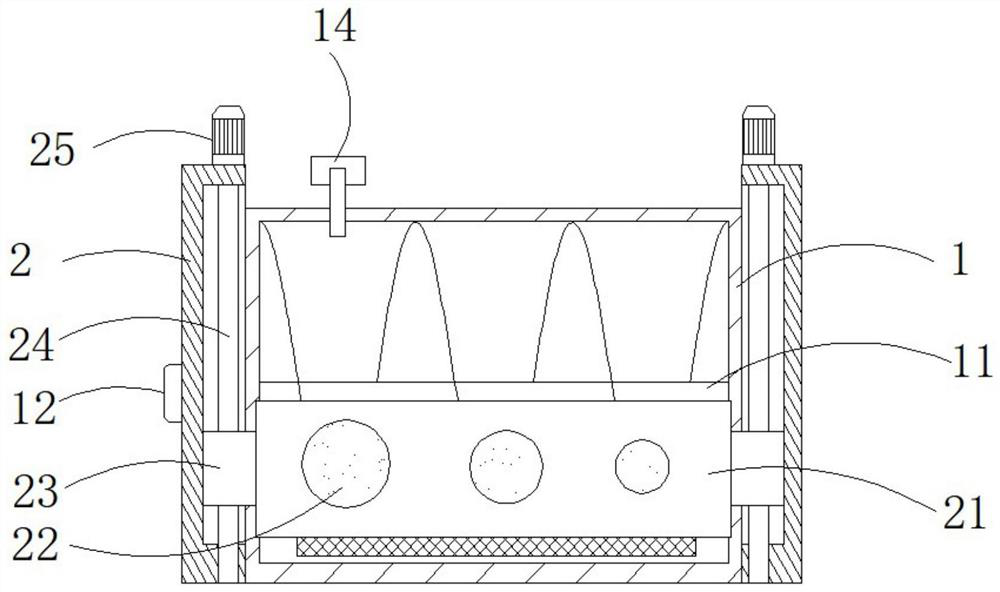

[0038] refer to figure 1 , a small-scale concrete trial mixing system for laboratories, including a pre-mixing box 1 located at the upper end of a base 9, a configuration table 2, a feeding auger 3 and a main mixing box 4, and concrete raw materials are arranged above the feed port of the pre-mixing box 1 The disposition table 2 is used for batching, and the discharge port of the pre-mixing box 1 is communicated with the feed port of the main mixing box 4 through the feeding auger 3 . Concrete raw materials enter the pre-mixing box 1 after batching through the configuration table 2, and then enter the main mixing box 4 through the feeding auger 3.

[0039] Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com