Automatic power supply plug-in system of torpedo car and plug-in control method of torpedo car

A torpedo tank car and plugging system technology, which is applied in the direction of electrical program control, tank car, connecting device connection/disconnection, etc., can solve the problems of large deviation of locomotive parking position, low plugging success rate, and plugging effect is not as good as manual operation, etc. , to achieve the effect of improving the level of automated production, improving the level of safety production, and avoiding personal injury accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A further detailed description will be made below in conjunction with the specific structure and steps of a torpedo tank car power supply automatic plugging system and its control method according to the present invention.

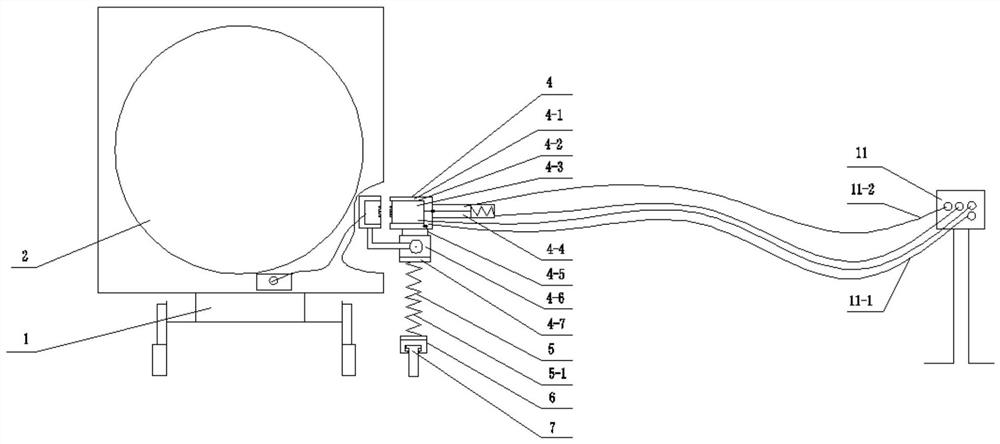

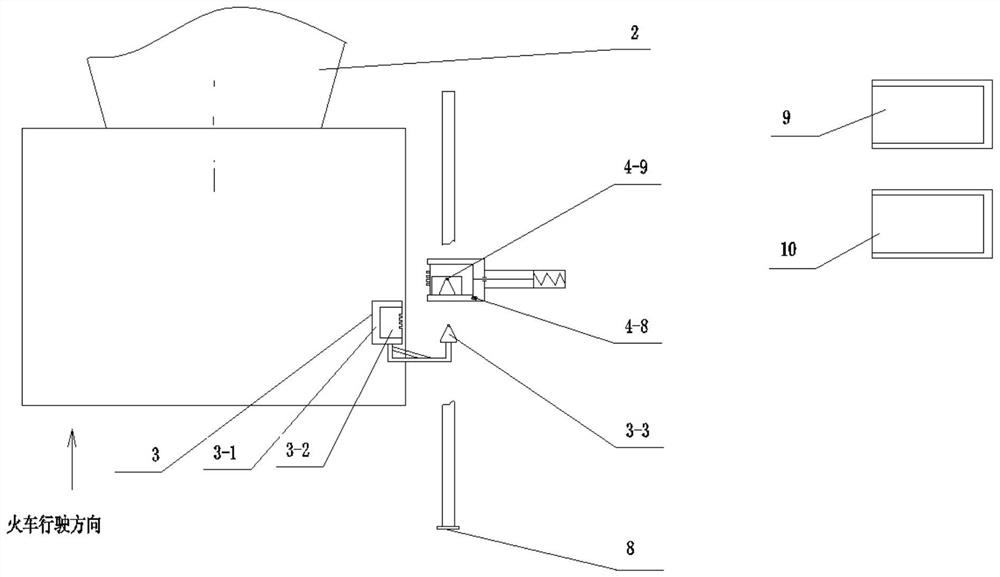

[0038] Such as figure 1 , figure 2 Shown is a schematic diagram of the composition and structure of the power supply automatic plugging system of the torpedo tanker of the present invention.

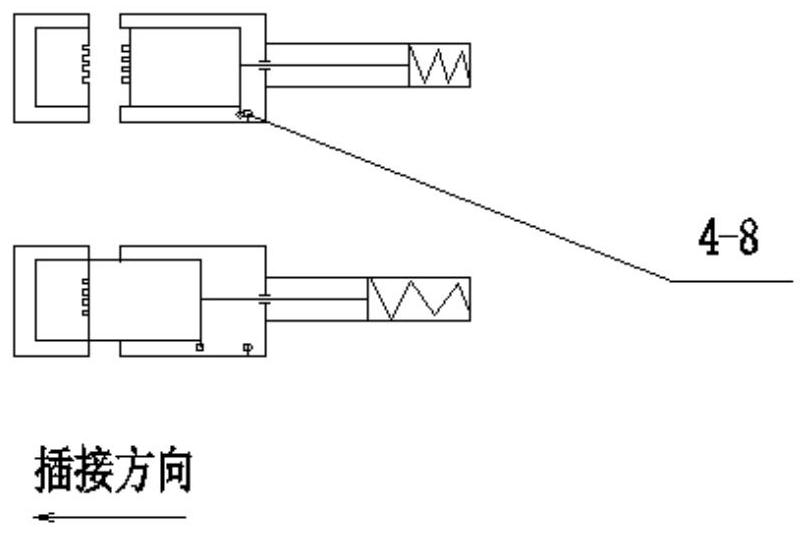

[0039] A power supply automatic plugging system for a torpedo tank car of the present invention comprises a socket device 3, a plug device 4 and its flexible support device 5, a follow-up trolley 6, a guide rail 7, a stop iron 8, a locomotive auxiliary operator 9, Auxiliary manipulator 10 for folding cans constitutes.

[0040] Described socket device 3 has a casing 3-1 that is installed on the torpedo tank car 1 car body, and a power socket 3-2 is housed in the casing 3-1. The power socket 3-2 is connected with the driving motor of the torpedo tank car 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com