Clothing treating device and method for controlling clothing treating device

A clothes treatment device and clothes treatment technology, which are applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of logic control risk, the main control unit of the laundry module of the display unit cannot be used in a standardized manner, etc., and achieve the benefits The effect of standardization and platformization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

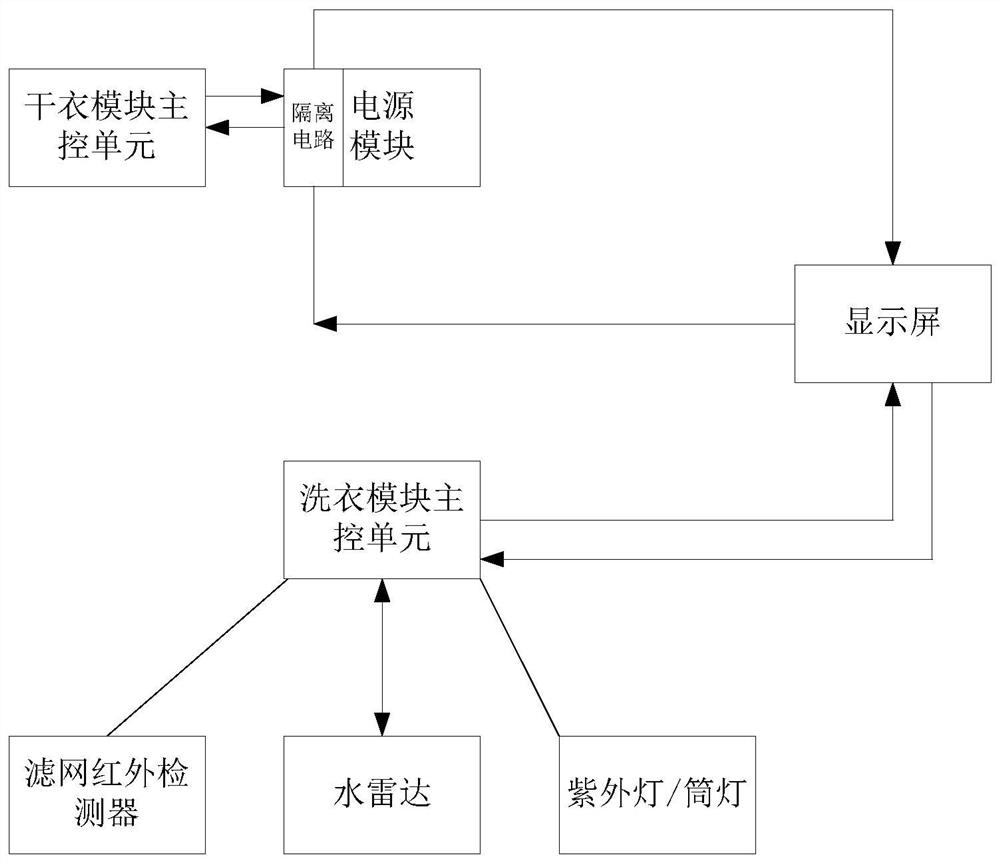

[0033] figure 2 It is a schematic structural diagram of an all-in-one washing and drying machine according to an embodiment of the present invention.

[0034] The washing and drying machine includes a drying module and a laundry module. The drying module is used to dry clothes, and the laundry module is used to wash clothes. The drying module and the laundry module can be arranged up and down. For example, the drying module is located in the laundry module Above, or, the drying module and the laundry module can also be arranged adjacent to each other on the left and right; the all-in-one washing and drying machine also includes: the main control unit of the drying module, the main control unit of the laundry module, a core board, a power module, and a display screen; among them, the core The board is respectively connected with the main control unit of the drying module and the main control unit of the laundry module, so that at least part of the programs of the main control ...

Embodiment 2

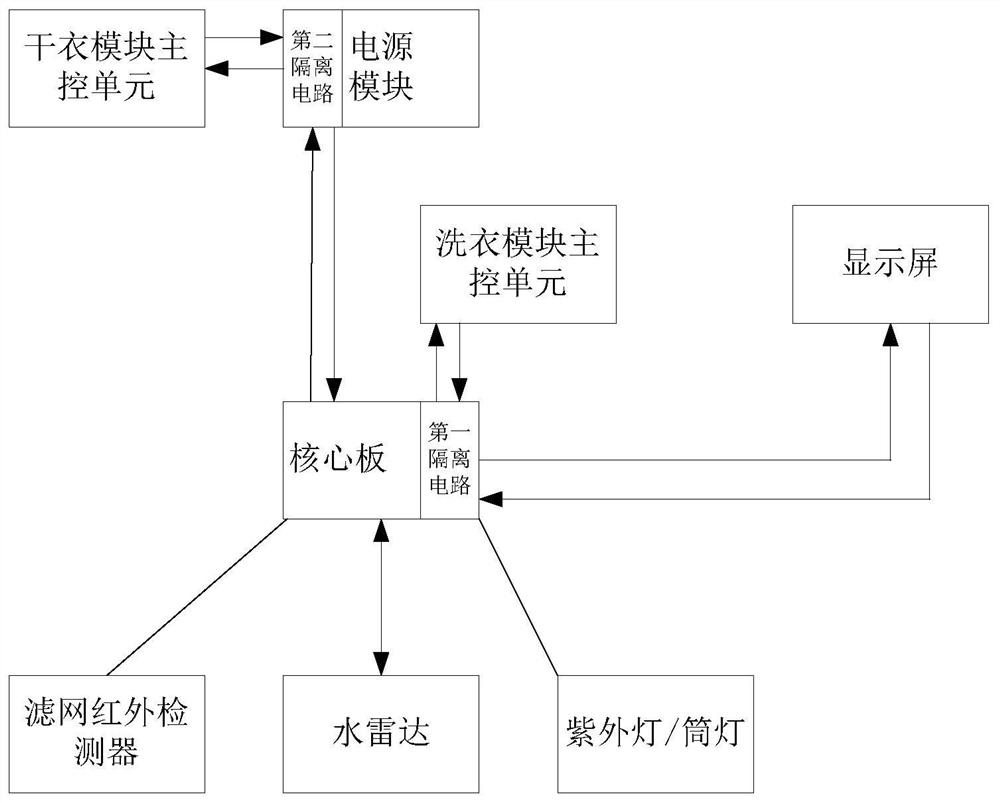

[0047] Figure 4 It is a schematic structural diagram of an all-in-one washing and drying machine according to an embodiment of the present invention. The main difference from the above embodiment is that the core board and the display screen are combined into one, the core board is changed to an AC / DC power module and isolated on the board, and the serial communication is only transparently transmitted on the AC / DC power module Do not perform instruction parsing. Mutex logic and instruction parsing are handled by the display.

[0048] The integrated washing and drying machine includes: the main control unit of the drying module, the main control unit of the laundry module, the AC / DC power supply module, and the display screen; among them,

[0049] In this embodiment, in order to ensure safe use, the display screen includes a first isolation circuit through which the AC / DC power supply module is connected; the communication between the display screen and the AC / DC power supp...

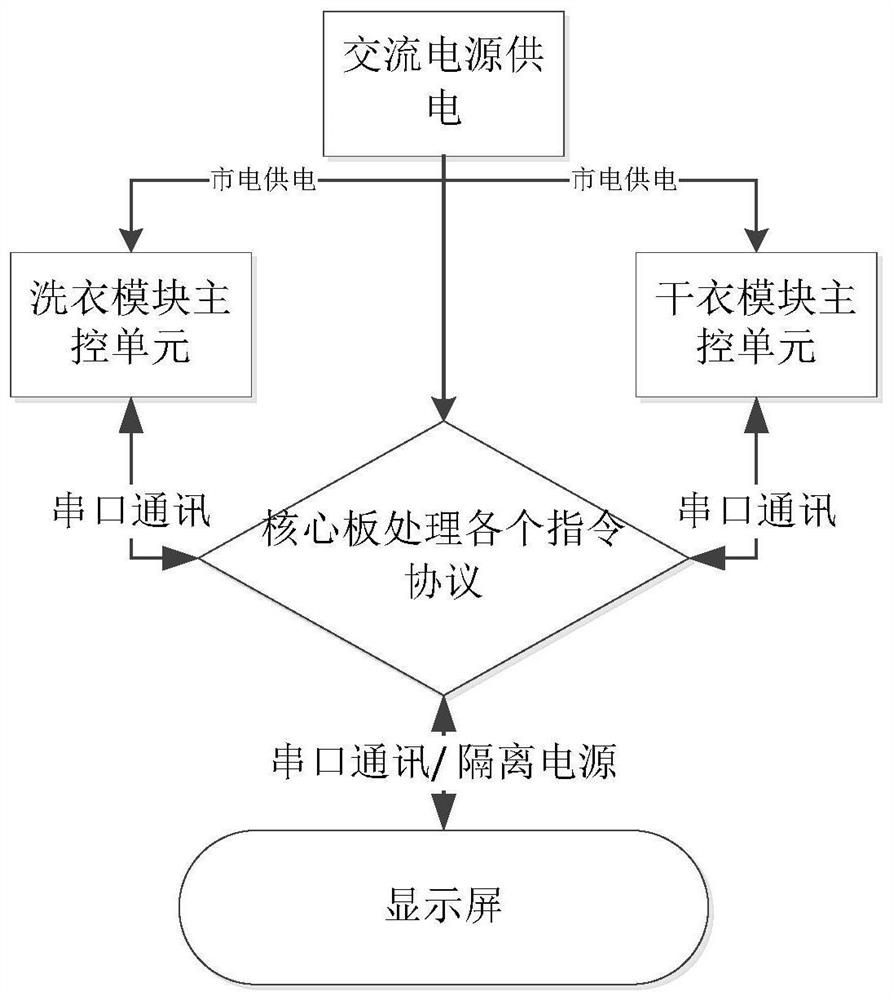

Embodiment 3

[0059] Figure 5 It is a schematic structural diagram of a washing machine according to an embodiment of the present invention. The main difference from the above embodiment is that this washing machine is not the integrated washing and drying machine of the above embodiment, but a washing machine with two or more washing modules.

[0060] The washing machine includes: the main control unit of the first laundry module, the main control unit of the second laundry module, a core board, a power module, and a display screen; wherein,

[0061] In this embodiment, in order to ensure the safety of use, the core board includes a first isolation circuit, and is connected to the main control unit of the first laundry module through the first isolation circuit; the communication between the core board and the main control unit of the first laundry module uses a UART half In duplex mode, TxD and RxD use a common communication line to transmit data in a master-slave manner. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com