Sound insulation type fabricated building wall convenient to mount

A building wall and prefabricated technology, applied in the direction of sound insulation, construction, building components, etc., can solve the problems of time-consuming and labor-intensive installation, affecting the work efficiency of installers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

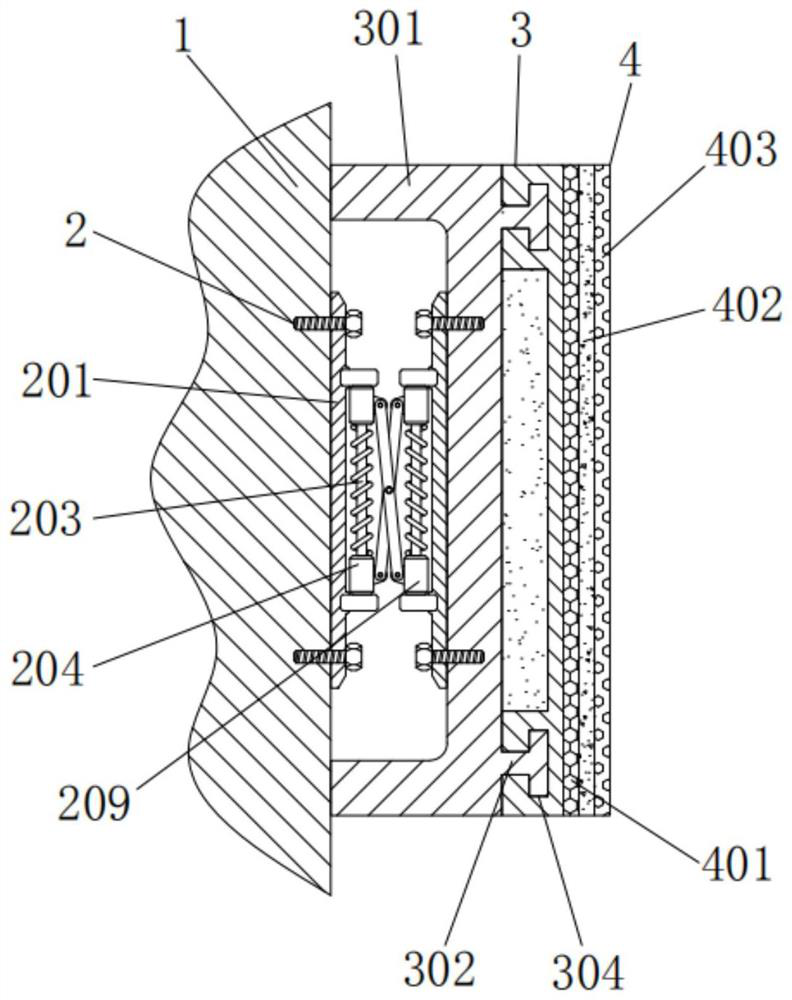

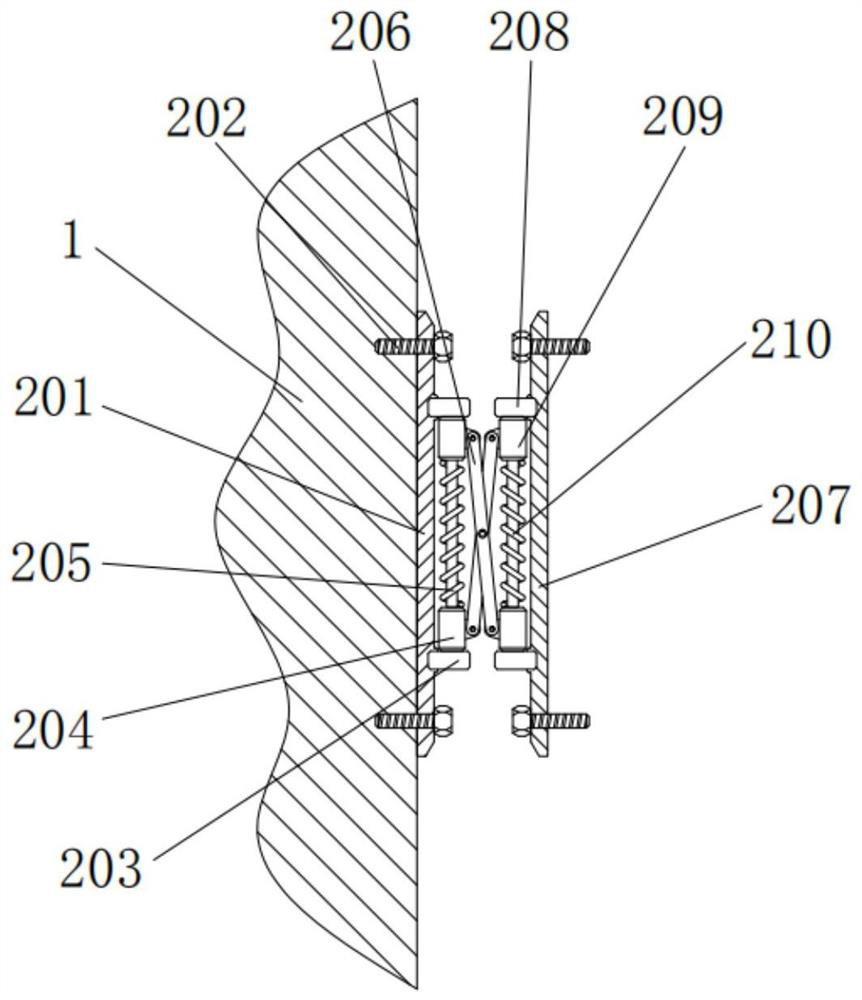

[0038] An easy-to-install sound-insulating prefabricated building wall, including a first wall 1, a connecting mechanism 2 is provided on the right side of the first wall 1, and the connecting mechanism 2 includes a first vertical plate 201, a bolt 202, a first slide Rail 203, the first sliding sleeve 204, the first spring 205, the rod body 206, the second vertical plate 207, the second slide rail 208, the second sliding sleeve 209 and the second spring 210, the first vertical plate 201 connects the first vertical plate 201 through the bolt 202 The right side of a body of wall 1 is screwed together, and the right side of the first riser 201 is fixedly connected with the first sliding rail 203, and the upper and lower sides of the outer wall of the first sliding rail 203 are slidingly connected with the first sliding sleeve 204, so that the first The sliding sleeve 204 can move up and down on the outer wall of the first slide rail 203, and the outer wall gap of the first slide r...

Embodiment 2

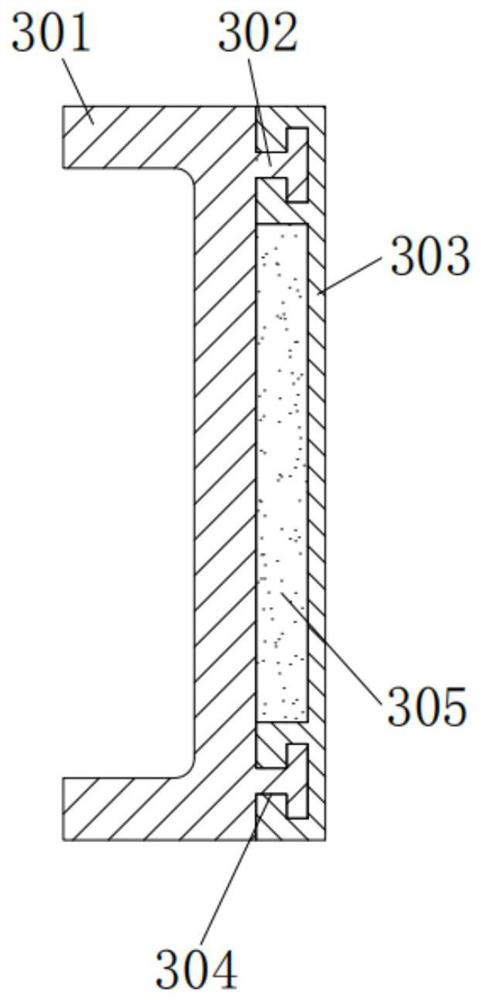

[0040] As an option, see figure 1 , 3, 4 and 6, a sound-insulated prefabricated building wall that is easy to install, the right side of the second riser 207 is provided with a fitting mechanism 3, and the fitting mechanism 3 includes a second wall body 301, a T-shaped block 302, a groove plate 303, T-shaped slot 304 and soundproof cotton 305, the second wall 301 is connected with the right side thread of the second riser 207 through the bolt 202, and the upper and lower right sides of the second wall 301 are processed with T-shaped blocks 302, The right side of the second wall 301 is attached with a grooved plate 303, and the upper and lower left sides of the grooved plate 303 are processed with a T-shaped groove 304, and the inner wall of the T-shaped groove 304 is attached to the outer wall of the T-shaped block 302. , so that the grooved plate 303 can be quickly spliced with the second wall 301 through the T-shaped block 302 and the T-shaped groove 304, and the inner wa...

Embodiment 3

[0043] As an option, see figure 1 , 4 And 5, a sound-insulating prefabricated building wall body that is easy to install, the right side of the groove plate 303 is provided with a sound-insulating layer 4, and the sound-insulating layer 4 includes a cement board 401, a sound-insulating felt 402 and a wood wool sound-absorbing board 403, and the cement board 401 is fixed On the right side of the grooved plate 303, the right side of the cement board 401 is bonded with a sound insulation felt 402. The sound insulation felt 402 is a flexible high-density coil made of rubber, polymer materials, etc. as the main raw materials. It is mainly used to match with gypsum board for sound insulation of walls and ceilings. It is also used for sound insulation and damping of pipes and mechanical equipment. The right side of sound insulation felt 402 is glued with wood wool sound-absorbing board 403, wood wool sound-absorbing board The surface texture of 403 shows elegant texture and unique t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com