An oil-absorbing anti-clogging structure of an automobile electric pump

An anti-clogging, electric pump technology, applied in charging systems, machines/engines, liquid fuel feeders, etc., can solve problems such as accumulation, and achieve the effect of ensuring normal use, stable operation, and smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

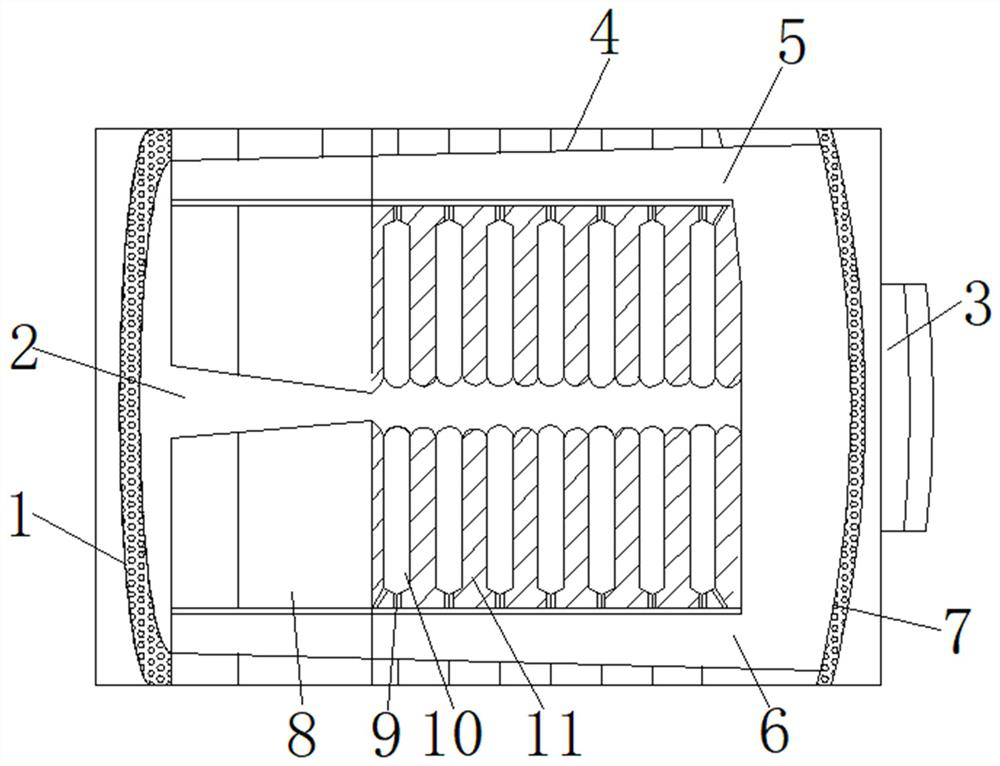

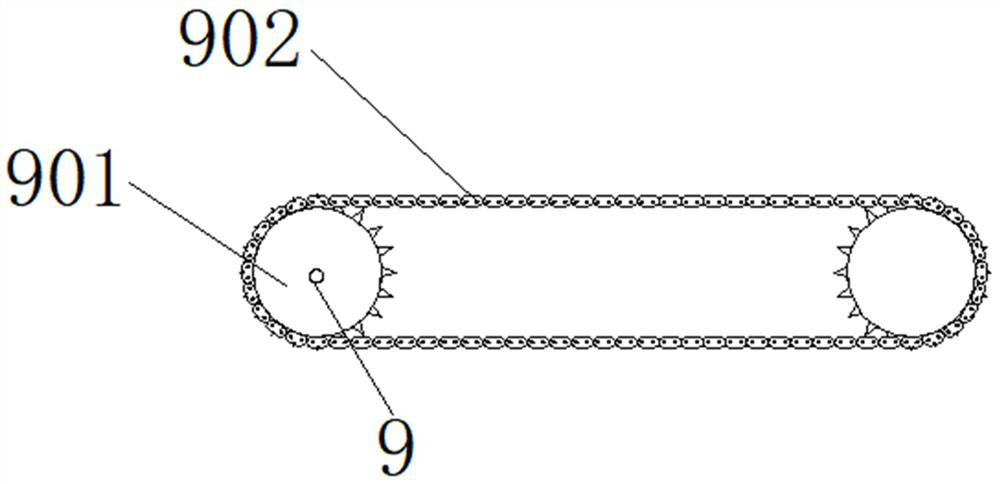

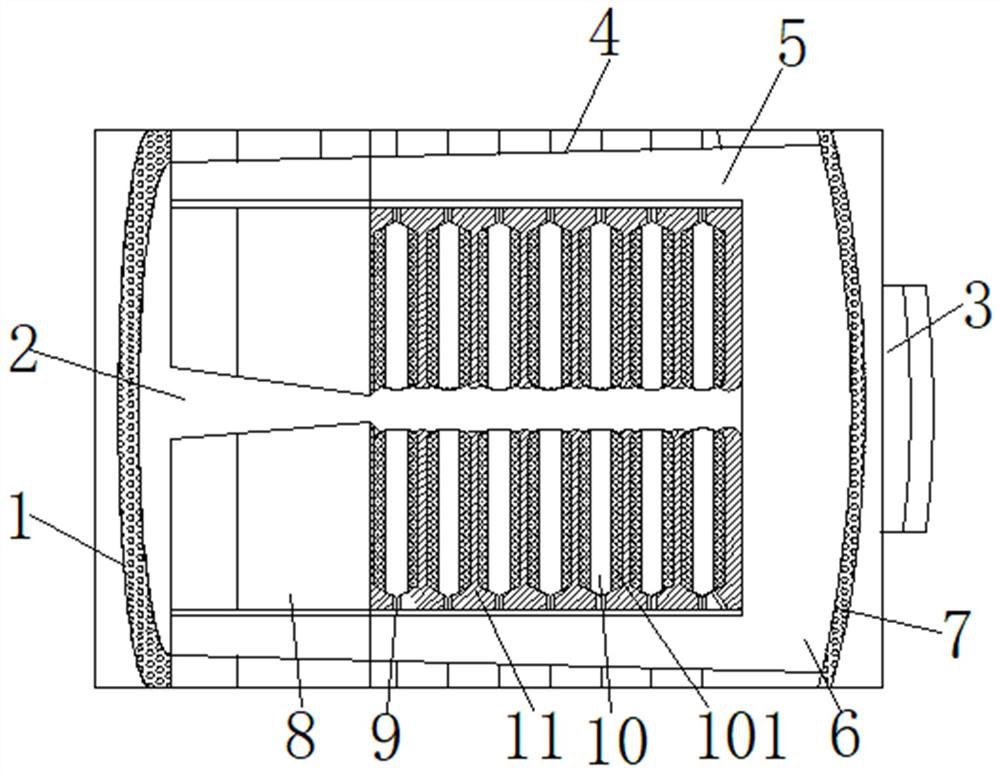

[0028] Such as Figure 1-5 As shown, it includes the oil inlet of the oil pump, and one end of the oil inlet of the oil pump is provided with a housing, and the inside of the housing includes a limit flow cavity (8) and a filter cavity, and the filter cavity includes several groups of uniformly arranged expansion arc plates (10 ) and the stacked filter plate (11), the two ends of the expansion arc plate (10) are provided with azimuth rotation column (9), and one end of the azimuth rotation column (9) is movably connected with a fixed rotation frame (12), and the azimuth rotation column ( One end of 9) is fixedly connected with a gear (901), and a motor is arranged inside the limit flow cavity (8), and a chain (902) is arranged at one end of the motor, and one end of the chain (902) is meshed with the gear (901). The laminated filter plate (11) and the expanded arc plate (10) are arranged indirectly with each other, the laminated filter plate (11) is fully close to the inner si...

Embodiment 2

[0034] Such as Figure 1-5As shown, it includes the oil inlet of the oil pump, and one end of the oil inlet of the oil pump is provided with a housing, and the inside of the housing includes a limit flow cavity (8) and a filter cavity, and the filter cavity includes several groups of uniformly arranged expansion arc plates (10 ) and the stacked filter plate (11), the two ends of the expansion arc plate (10) are provided with azimuth rotation column (9), and one end of the azimuth rotation column (9) is movably connected with a fixed rotation frame (12), and the azimuth rotation column ( 9) is fixedly connected with a gear (901) at one end, and a motor is arranged inside the limit flow cavity (8), and a chain (902) is arranged at one end of the motor, and one end of the chain (902) is meshed with the gear (901); The laminated filter plate (11) and the expanded arc plate (10) are arranged indirectly, and the laminated filter plate (11) is sufficiently close to the inner side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com