Waterproof device for mining motor winding conducting rod

A technology of waterproof devices and conductive rods, applied in electromechanical devices, electric components, windings, etc., can solve the problems of zero insulation resistance, affecting production efficiency, affecting the use of motors, etc., and achieve the effect of preventing creepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

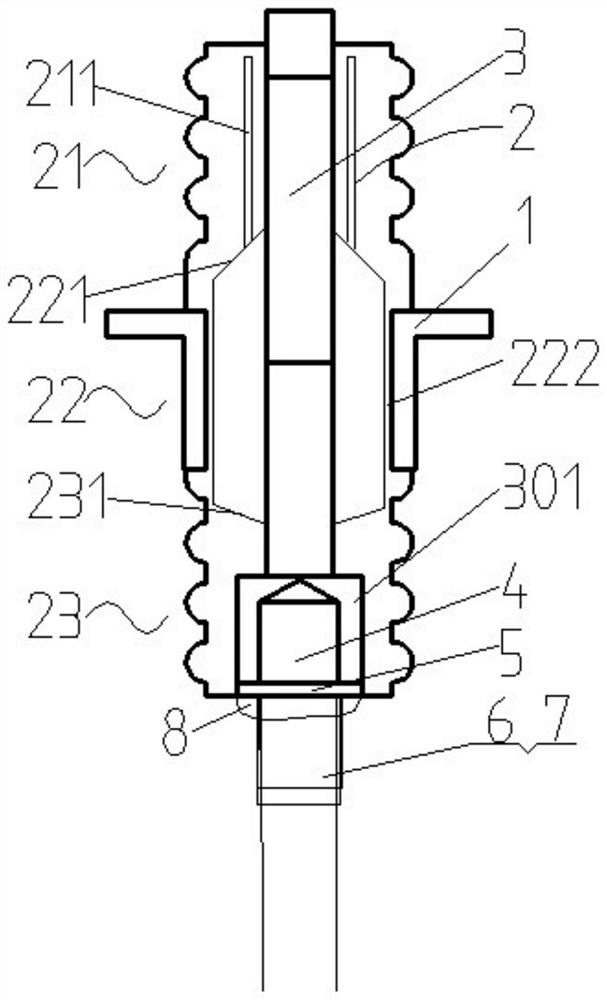

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the figure, a mine motor winding conductive rod waterproof device includes a wiring cavity 1, and the wiring cavity 1 is fixed at the middle position of the heat conducting shell 2. 2 is provided with a conductive rod 3, and the lower end of the conductive rod is provided with a circular notch 301, and the winding lead-out wire 4 arranged under the conductive rod 3 abuts against the circular notch 301 of the conductive rod. The gap between the notch and the winding lead-out wire is provided with a sealing ring 5, and the heat-shrinkable tube 6 arranged on the outside of the winding lead-out wire 4 seals the winding lead-out wire 4 through a self-adhesive tape 7; There is silicone rubber 8; the heat conduction housing 2 includes a sealing part 21, a heat dissipation part 22, and a connecting part 23; the inside of the sealing part is provided with a slender h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com