Extrusion device

An extrusion device and extrusion head technology, applied in the field of extrusion devices, can solve problems such as hindering the accurate calibration of materials, increasing the processing speed, and damaging the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

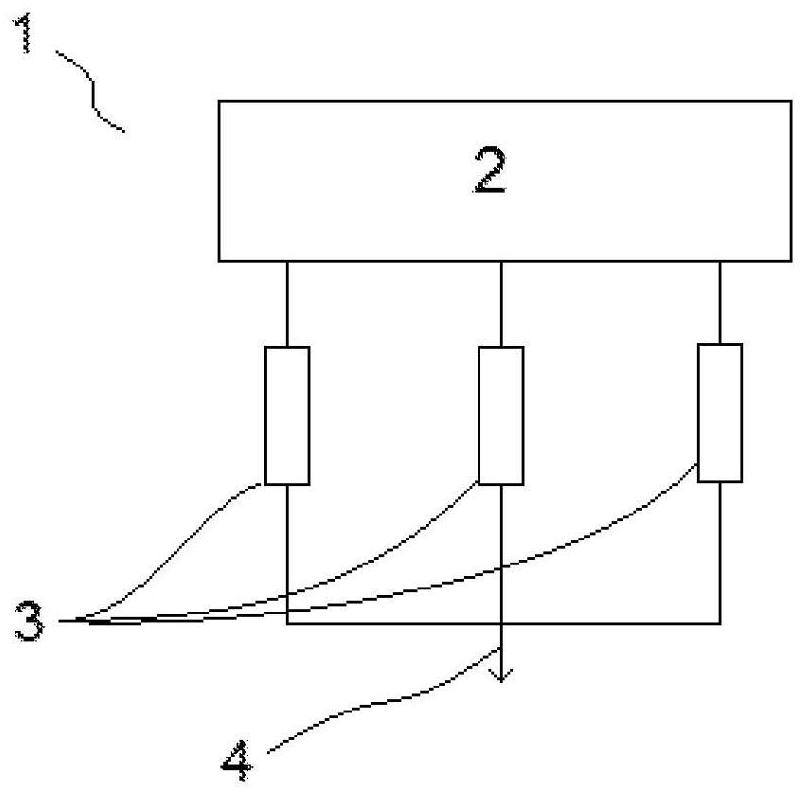

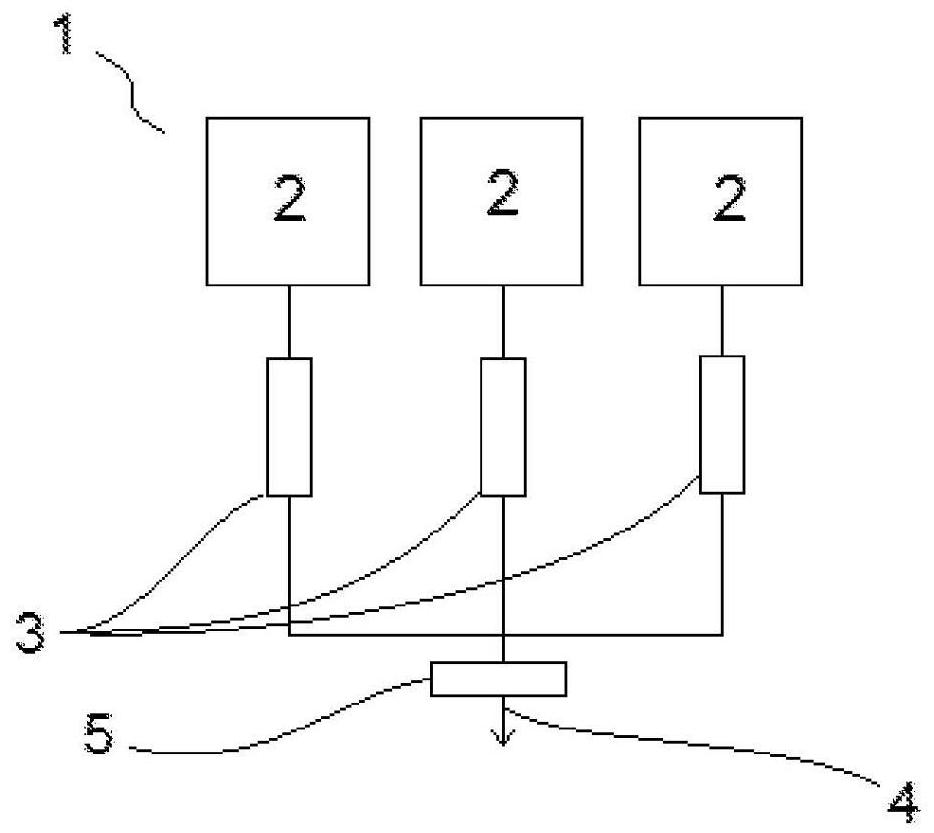

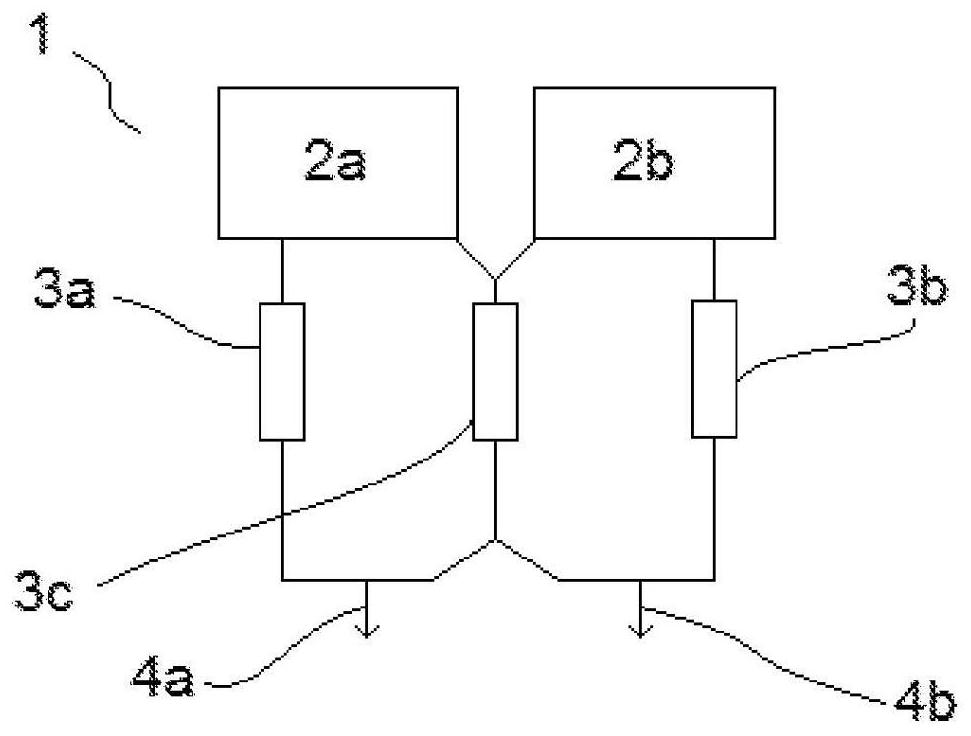

[0055] In the figures, reference numeral 1 generally refers to an extrusion device according to the invention.

[0056] The extrusion device 1 comprises at least one supply station 2 , a plurality of pushers 3 and at least one extrusion head 4 .

[0057] Supply station 2 refers to a tank, hopper or any tall container suitable for storing the material to be extruded and supplying it to subsequent parts of the extrusion device (arranged downstream of supply station 2 ).

[0058] For the purposes of this specification, the generic term "material to be extruded" refers to any material known to be used in the field of extrusion processes, eg plastics, polymers or other materials.

[0059] Each pusher 3 is operatively connected to at least one supply station 2 to be able to receive therefrom the material to be extruded.

[0060] The extrusion head is connected to at least one pusher 3 to receive therefrom the material to be extruded.

[0061] In other words, the extrusion device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com