Blast furnace coal injection device capable of controlling oxygen content of medium-speed mill inlet and control method thereof

A blast furnace coal injection and control method technology, applied in the blast furnace, blast furnace details, blast furnace parts, etc., can solve the problem of exhaust gas oxygen content that has not been discussed, and achieve the effect of reducing safety hazards and controlling O2 content accurately and precisely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

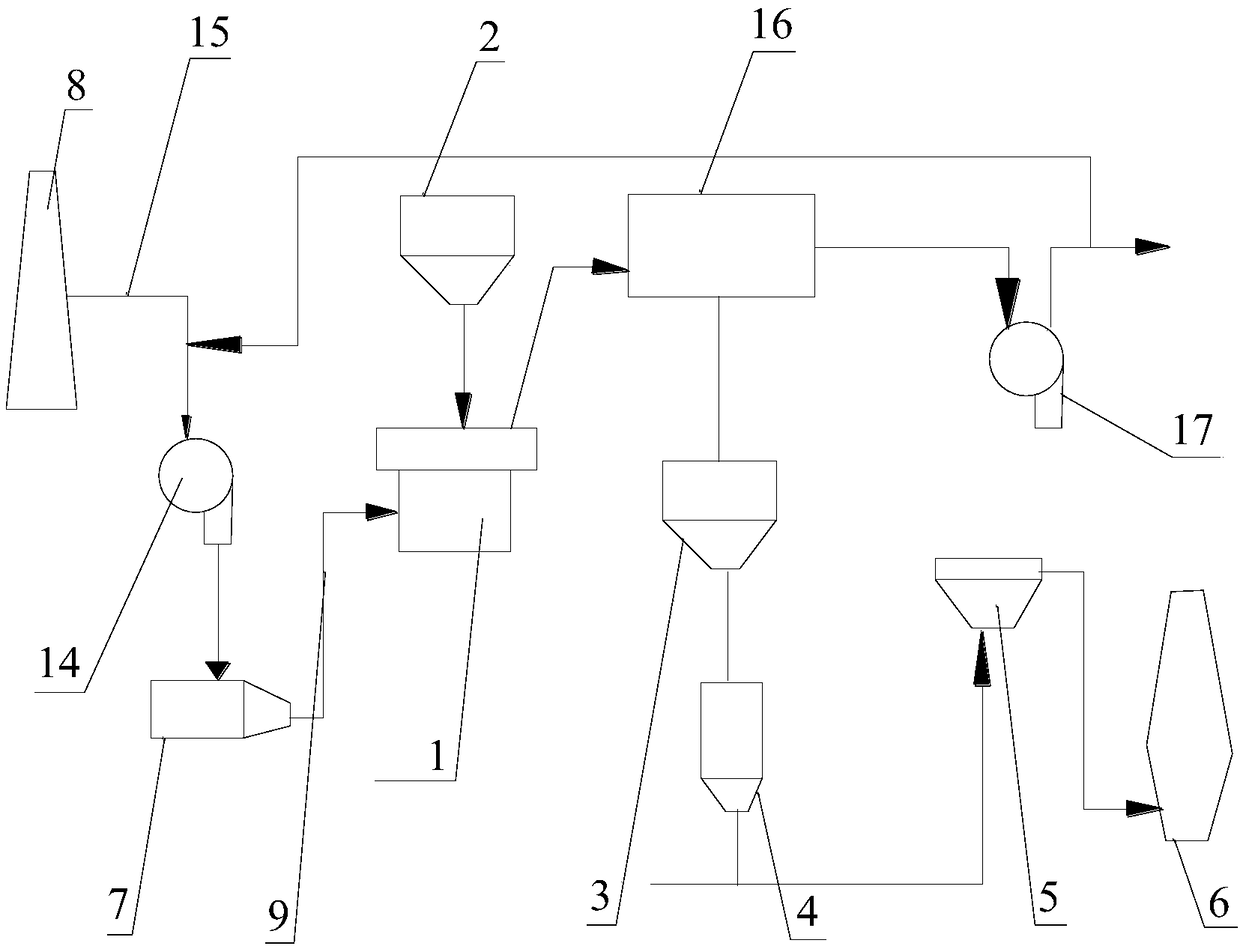

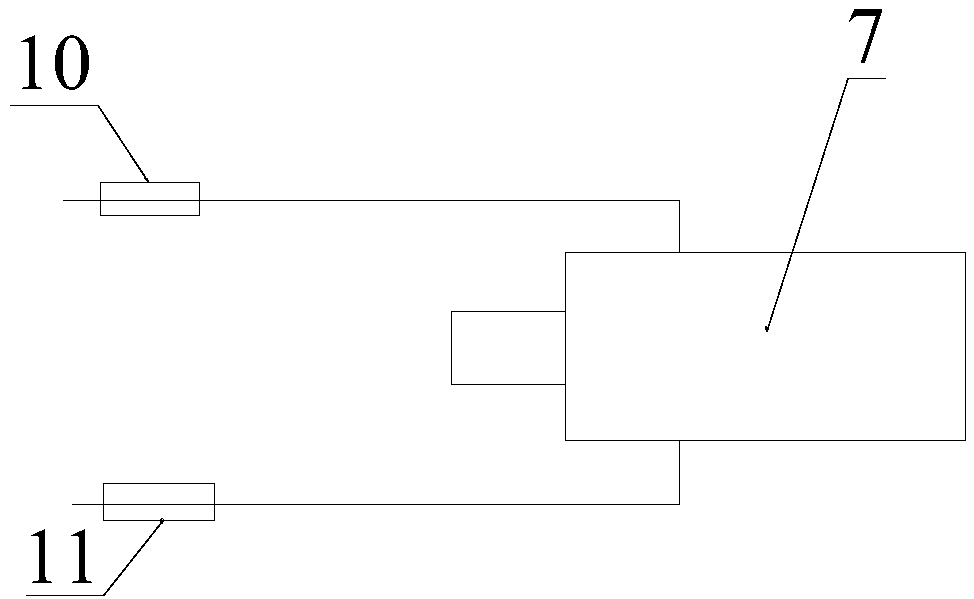

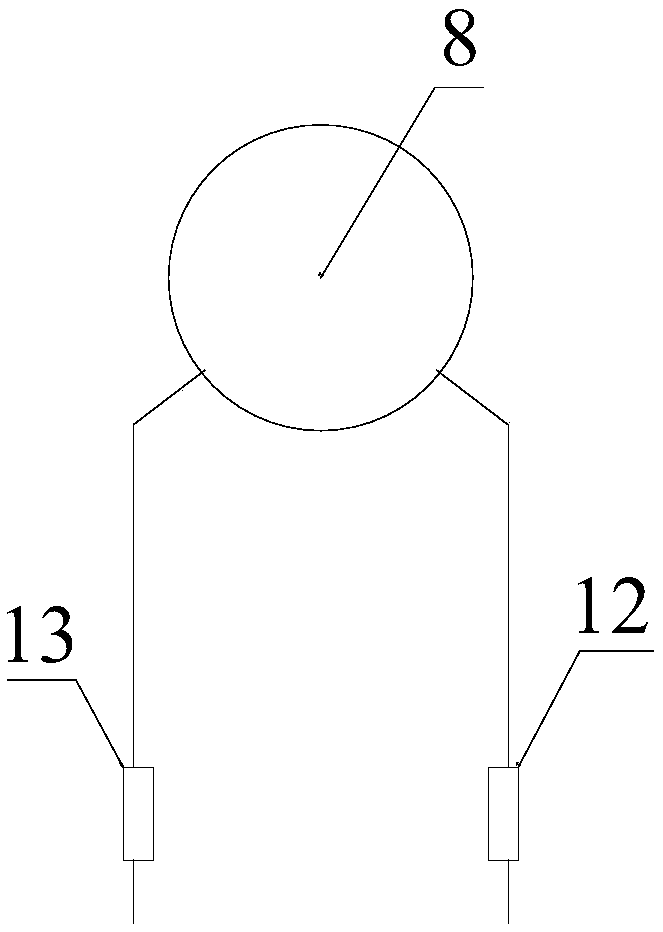

[0029] Such as figure 1 As shown, the blast furnace coal injection device capable of controlling the oxygen content at the medium-speed mill inlet of the present invention includes a medium-speed mill 1 and a raw coal bunker 2 connected to the medium-speed mill 1, and a pulverized coal bunker 3 is provided at the outlet of the medium-speed mill 1. The pulverized coal bin 3 is connected with the injection tank 4, the injection tank 4 is connected with the distributor 5, the distributor 5 is connected with the blast furnace 6, the entrance of the medium speed mill 1 is connected with the flue gas furnace 7, and the entrance of the flue gas furnace 7 is A hot blast stove 8 is connected, and a first test sampling hole 9 is provided at the entrance of the medium-speed mill 1. As shown in FIG. A flue gas furnace gas flow regulating valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com