Intelligent vertical tank microwave sterilizer

A microwave sterilization and microwave generator technology, applied in chemical instruments and methods, foam dispersion/prevention, mixers, etc., can solve the problems of stacking thickness that cannot be too thick, limited by site factors, and short effective microwave distance. Achieve the effect of improving the taste of materials and the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

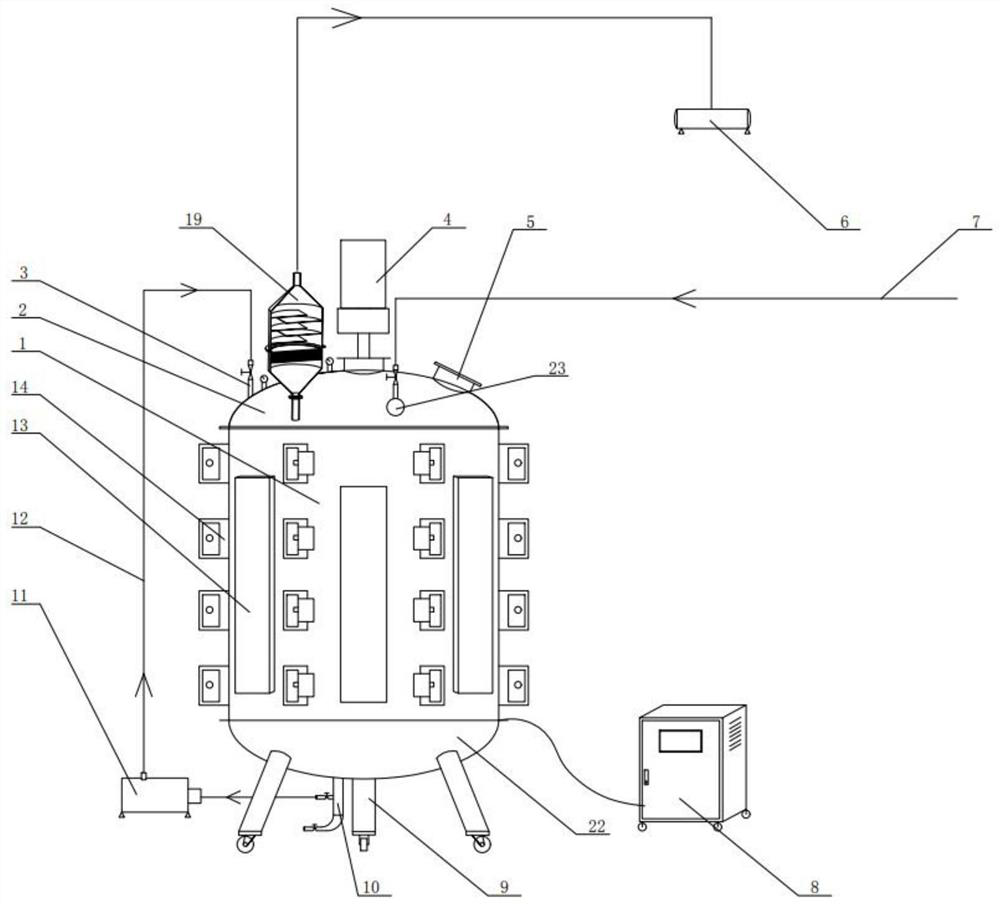

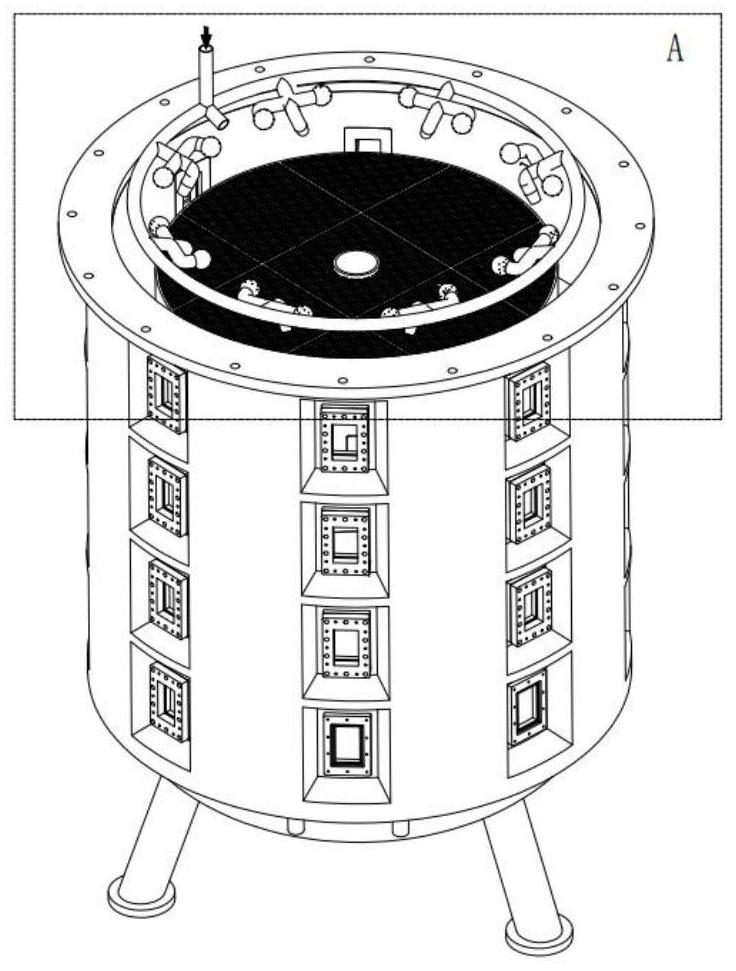

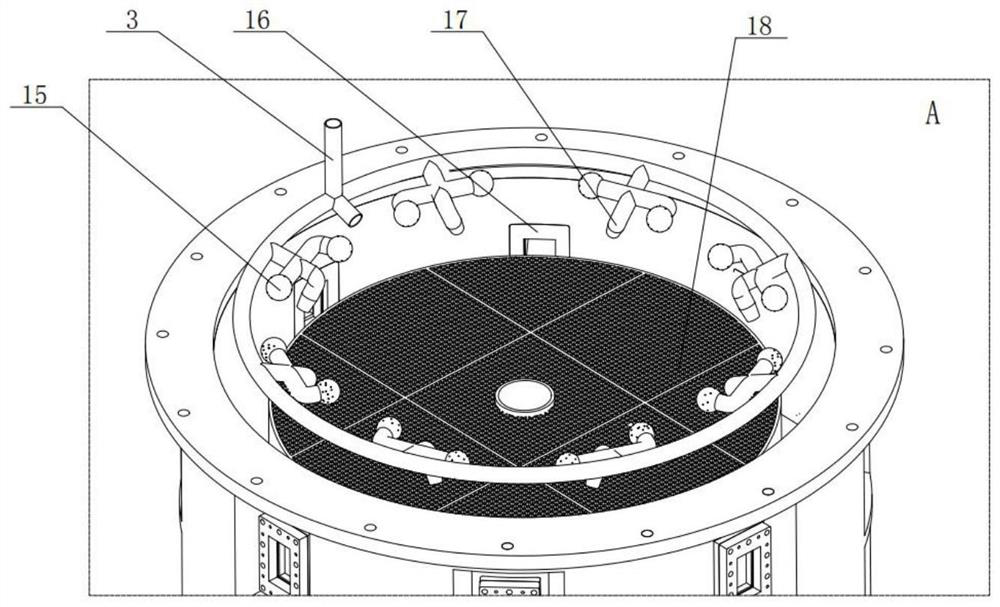

[0029] A vertical tank body microwave sterilizer, comprising: a tank body, a microwave sterilization system and a material circulation system; The bottom of the head 22 is provided with a material outlet 10, and the upper head 2 is provided with a material inlet 3. The material circulation system includes a circulation pump 11 and an annular atomizing nozzle; the circulation pump 11 passes through the material outlet 10 and the material inlet 3 respectively. The circulation pipeline 12 is connected and used for the circulation of the material and liquid in the tank; the microwave sterilization system includes a plurality of microwave generators 14 and microwave windows 16 corresponding to the microwave generators 14, and the microwave generators 14 are arranged in a rectangular array on the tank body 1 outer wall, forming a plurality of microwave generator rows; the microwave window 16 is arranged on the inner wall of the barrel body 1, and the surface of the microwave window 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com