Composite forming device and method for heterogeneous laminated plates with electric current and friction assisted heating

A technology of auxiliary heating and composite forming, which is applied in the field of mechanical manufacturing and processing, can solve the problems of drum-shaped parts, inability to achieve real-time contact, and low contour accuracy, and achieve good welding quality, stable current density, and reduced procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

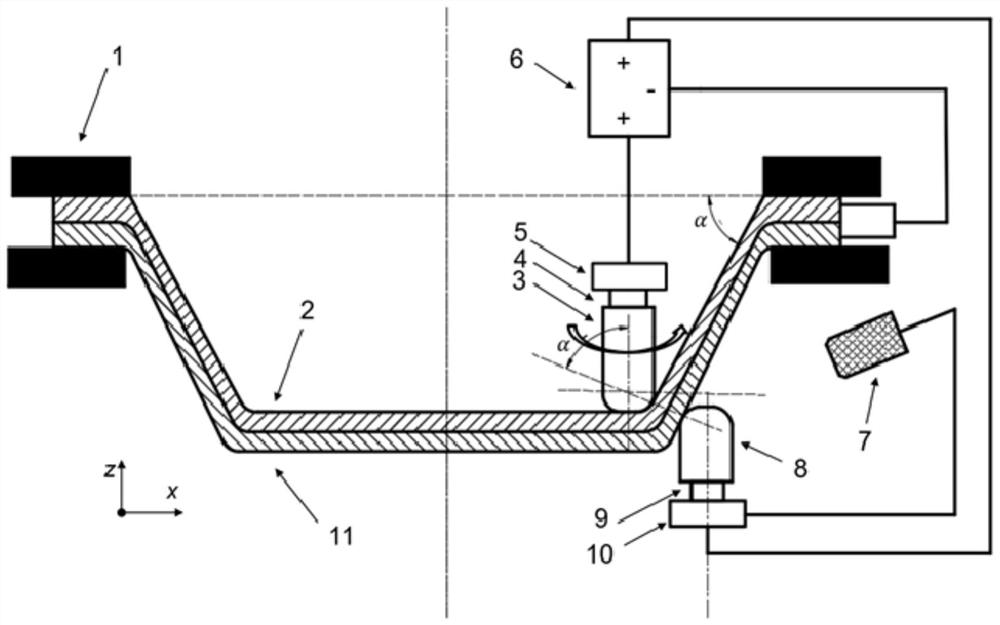

[0041] Such as figure 1 A current and friction assisted heating composite forming device for heterogeneous laminated plates with two-point progressive and synchronous connection, including clamping heterogeneous laminated plates (first metal plate 2, second metal plate 11) to be formed Fixture 1, two tool head assemblies for forming heterogeneous laminated boards, infrared thermometer 7, adjustable time-varying power supply 6, each tool head assembly includes a main drive control unit (first drive control unit) connected in sequence 5. The second drive control unit 10), the spindle motor (the first spindle motor 4, the second spindle motor 9), the tool head (the first tool head 3, the second tool head 8), the main drive control unit realizes the displacement through the motor Control, the positive pole of the adjustable time-varying power supply 6 is connected to the two tool heads, and the negative pole is connected to the heterogeneous laminated board to form a closed loop, ...

Embodiment 2

[0054] The heterogeneous laminates include stacked first metal plates 2 and second metal plates 11 of different materials, and the composite forming device for heterogeneous laminates heated by electric current and friction includes a first metal plate in rotational contact with the first metal plate 2. The tool head assembly, the second tool head assembly in rotational contact with the second metal plate 11, and the adjustable time-varying power supply 6, the adjustable time-varying power supply 6 is respectively connected with the first tool head assembly, the second tool head assembly and the heterogeneous stack The ends of the laminates are electrically connected.

[0055] Wherein, the adjustable time-varying power supply 6 includes two positive poles and one negative pole, the two positive poles are respectively electrically connected to the first tool head assembly and the second tool head assembly, and the negative pole is electrically connected to the end of the heterog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com