Multi-station clamp and milling machine with same

A multi-station and fixture technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of low processing efficiency of milling machines, achieve the effects of improving processing accuracy and quality, improving work efficiency, and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

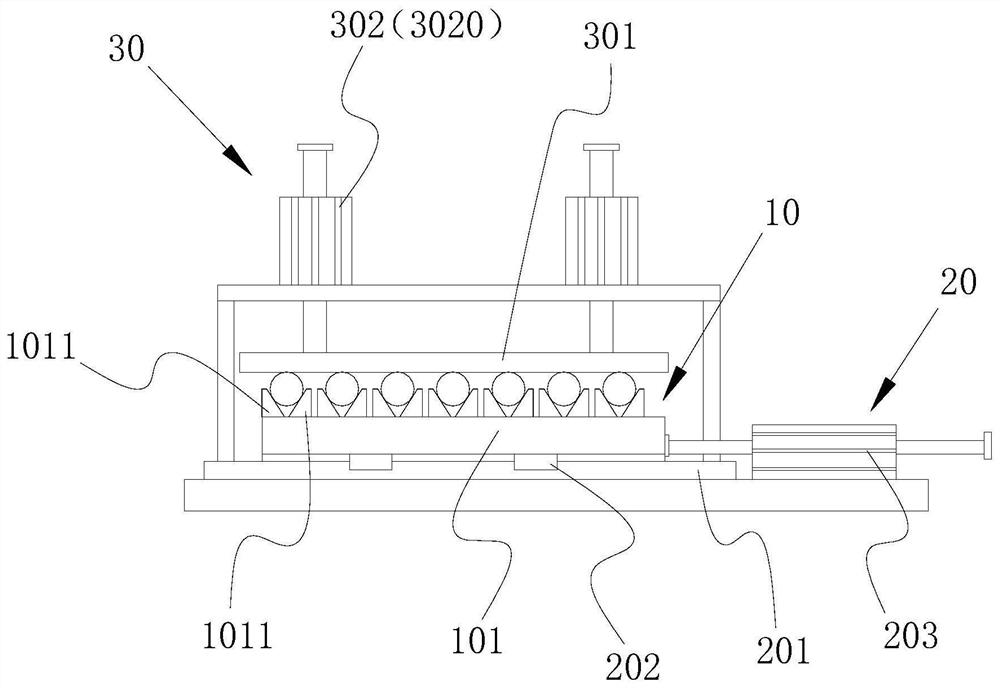

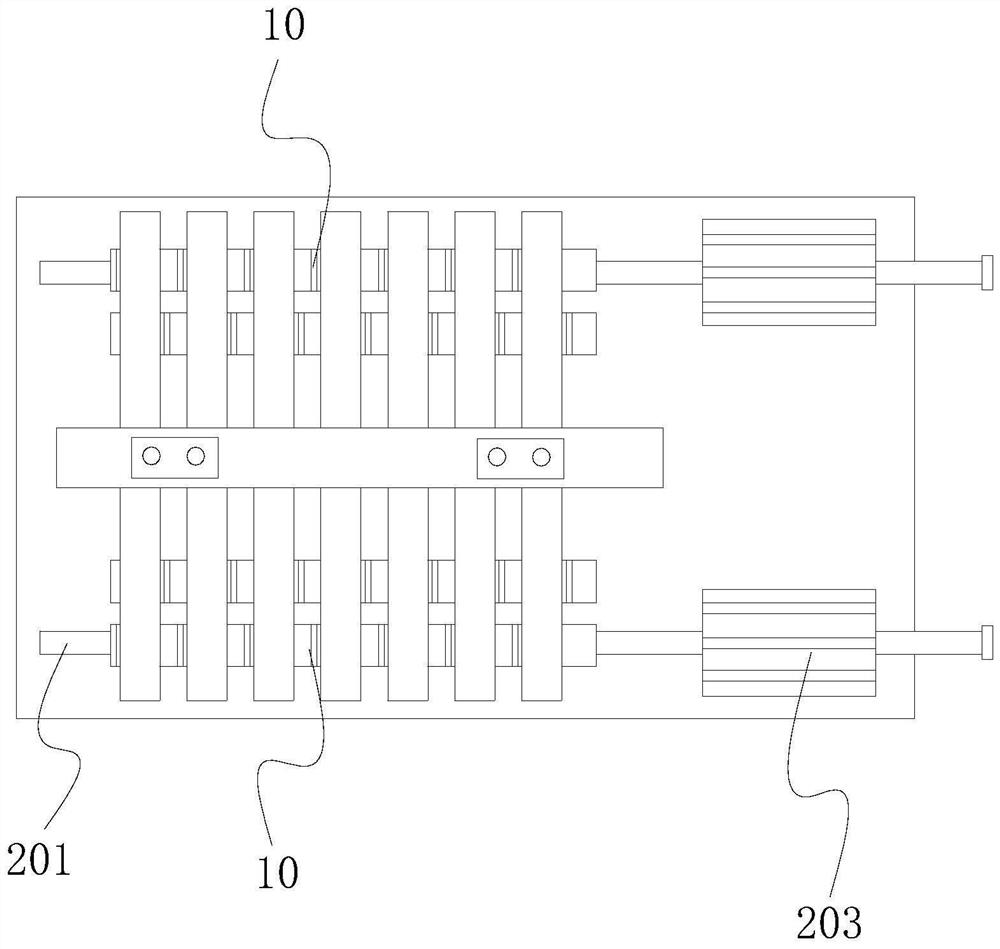

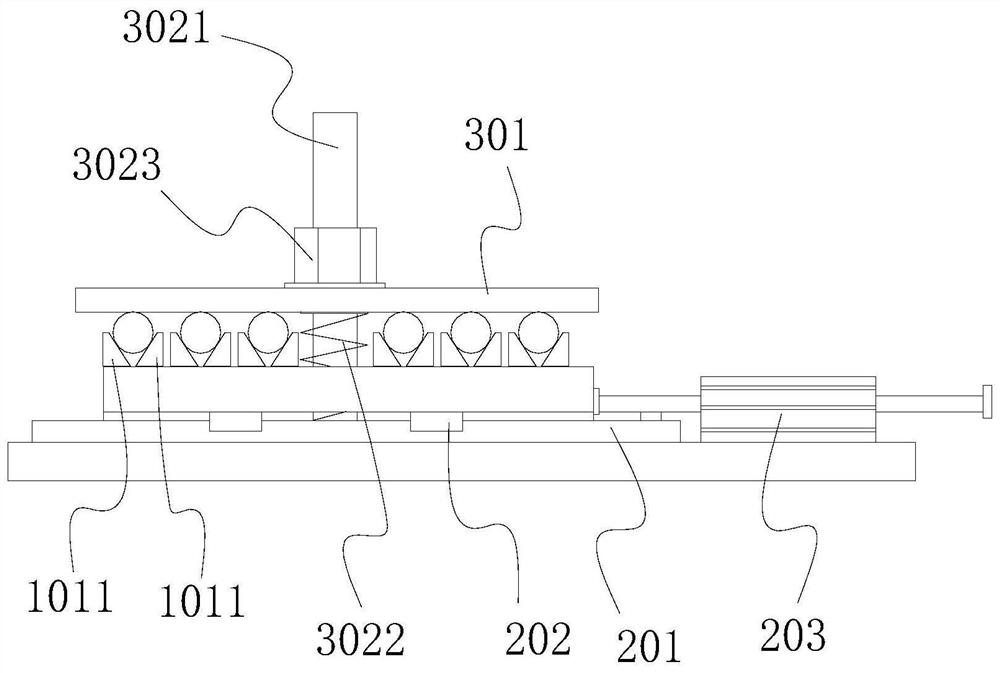

[0033] See figure 1 with figure 2 , This embodiment provides a multi-station clamp, including a clamp block 10, an adjusting slide rail 20, and a pressing mechanism 30. The clamp block 10 has two relatively sliding clamping bars 101, and the two clamping bars 101 have straight lines at equal intervals. The inclined surface protrusions 1011 are arranged, and the inclined surface protrusions 1011 on the two clamping strips 101 are arranged in a facing direction, and every two facing inclined surface protrusions 1011 are used to clamp a workpiece. Therefore, the two inclined protrusions 1011 facing each other on the two clamping strips 101 can form an orthographic V-shaped or inverted isosceles trapezoid groove, and multiple grooves can be placed on the clamping block 10 The workpiece, and then realize the processing of multiple workpieces, and improve the processing efficiency.

[0034] In this embodiment, there are two sets of clamping blocks 10, and the two sets of clamping bloc...

Embodiment 2

[0042] See Figure 5 This embodiment provides a milling machine with a multi-station clamp, including the multi-station clamp 1 described in the first embodiment. When processing shaft workpieces, when multiple shafts are clamped on the clamping block 10 at the same time by a multi-station fixture, the milling cutter 2 of the milling machine can machine the shaft surface, or punch the shaft, etc. Machining multiple workpieces at one time increases the machining time of the milling machine, reduces the number of workpiece preparations, and then reduces the time for workpiece preparation to achieve the purpose of improving work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com