Packaging bag production equipment

A technology for production equipment and packaging bags, applied in the field of packaging bag production equipment, can solve the problems of affecting the effect of packaging fit, colloid melting, uneven colloid distribution, etc., and achieve the effect of saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

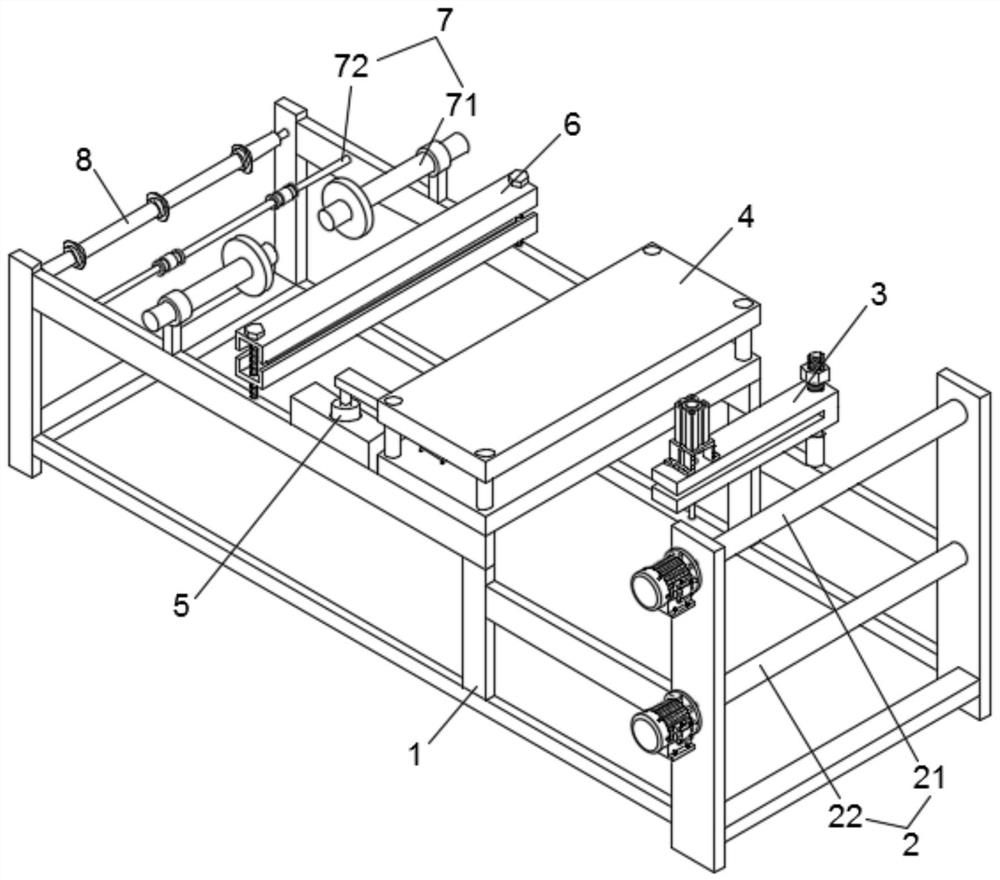

[0049] Such as figure 1 As shown, this embodiment discloses a packaging bag production equipment, including a frame 1, and also includes a discharge device 2, a punching device 3, a heat sealing device 4, a cooling soot blowing device 5, Cleaning device 6, welting device 7 and cutting device 8.

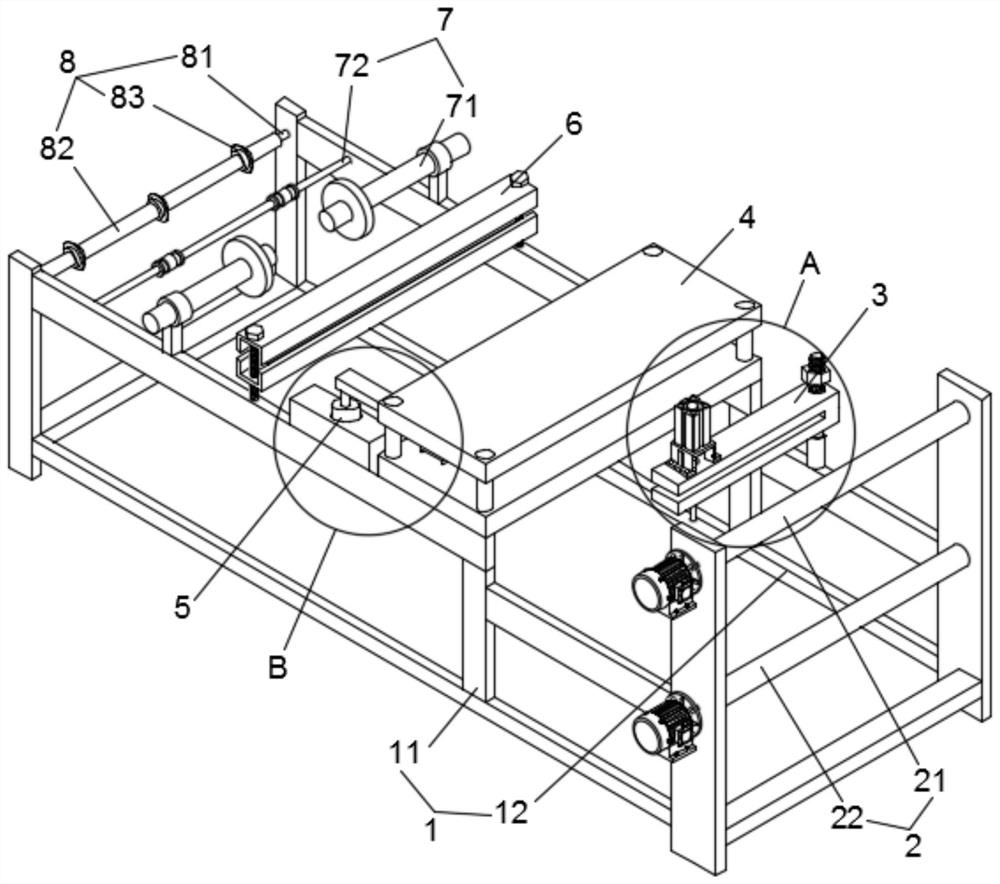

[0050] Such as figure 2 As shown, the frame 1 of the present embodiment includes a first frame 11 and a second frame 12, the first frame 11 and the second frame 12 are symmetrically arranged on both sides of the packaging bag delivery path, and the first frame 11 and the second frame 12 are connected by reinforcing rods, and the two ends of the reinforcing rods are respectively welded and fixed to the undersides of the first frame 11 and the second frame 12, and can also be fixedly connected by bolts or screws.

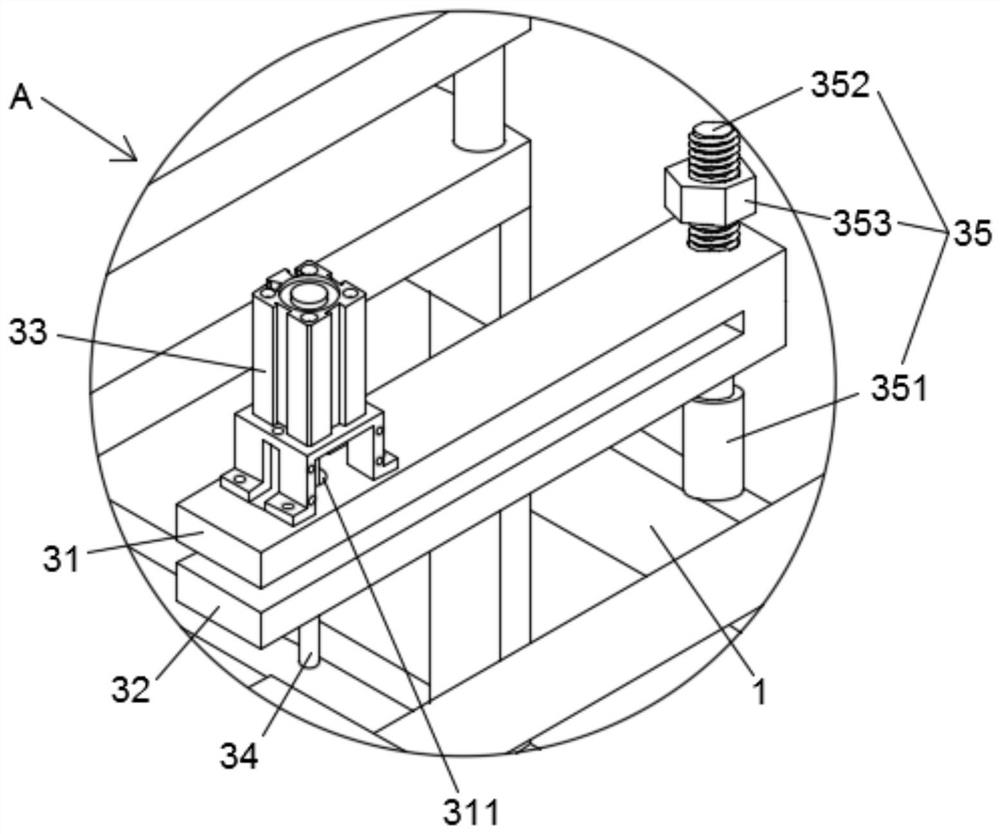

[0051] Such as figure 1 , figure 2 and 3 shown, and specifically figure 1 With reference to the orientation, the punching device 3 includes an upper platen 31, a lowe...

Embodiment 2

[0072] The difference between this embodiment and the above-mentioned embodiment is that: figure 1 As shown, the upper wiping layer 622 and the lower wiping layer 632 of the present invention are any one of a sponge layer, a non-woven fabric layer or a gauze layer.

Embodiment 3

[0074] The difference between this embodiment and the above-mentioned embodiment is that: figure 2 , Figure 7 As shown, the cutting device 8 of the present embodiment can also be driven by a motor. The motor adopts an existing motor bracket and is equipped with bolts or screws to be installed on the outer wall of the frame 1, and the output shaft of the motor is connected to the frame 1. Bearings are used to connect between them, the output shaft of the motor stretches out to the inside of the frame 1, one end of the connecting rod 81 is welded and fixed with the output shaft end of the motor, and the other end of the connecting rod 81 is connected with the other side of the frame 1 by a bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com