Printing equipment convenient to store and storage method thereof

A technology for printing equipment and printing surfaces, applied in printing devices, printing, etc., can solve the problems of manpower, material resources, time, inconvenient storage and transportation, and difficult to use space, so as to make full use of storage space, facilitate storage and transportation, and upgrade The effect of single shipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

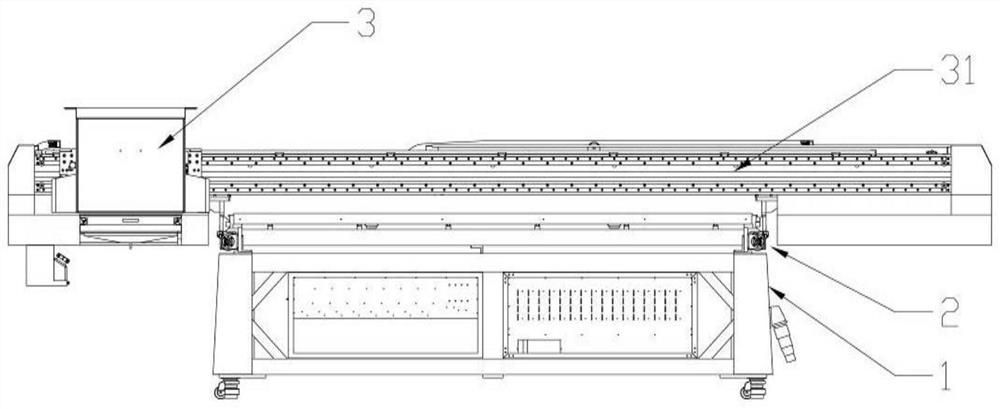

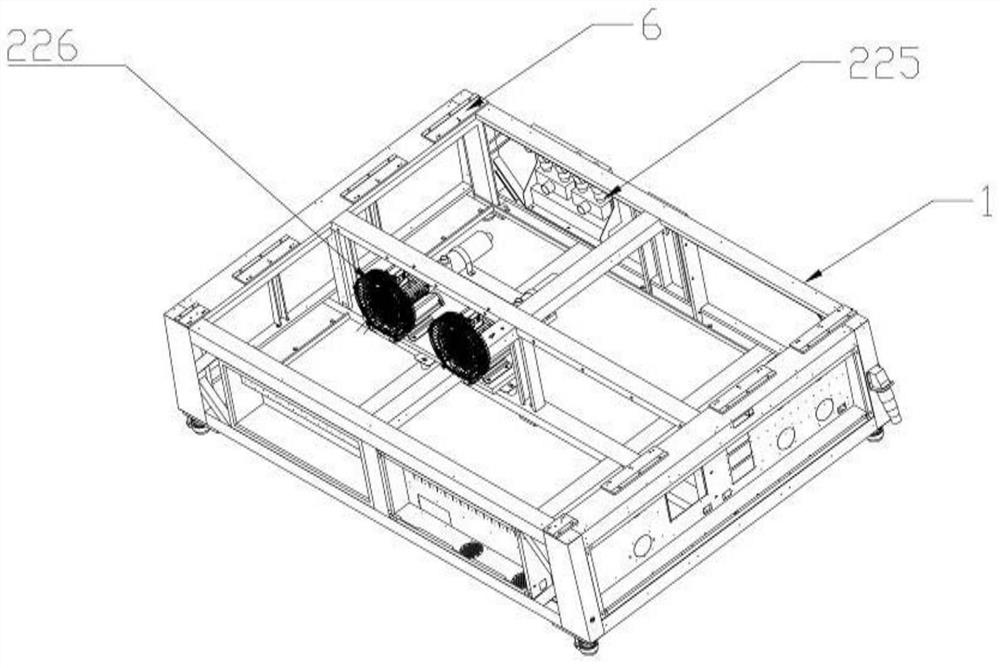

[0055] Such as figure 1 , 3 , 4, and 5, this embodiment discloses a printing device that is convenient for storage, including a base 1, an intermediate platform 2, and a spray vehicle 3. The base 1 is a cuboid structure formed by fixing multiple long beams 11 to each other; the The intermediate platform 2 includes a support adjustment frame 21 and a printing platform 22, the support adjustment frame 21 is detachably connected to the base 1; the printing platform 22 is installed on the support adjustment frame 21, and the upper surface of the printing platform 22 is used as a printing surface The both sides of described support adjustment frame are provided with guide rail 211, and described spray car 3 is connected with guide rail 211 by the spray car support 31 that is arranged on printing platform top, and spray car support is connected with described guide rail by connecting plate 32, so The vehicle spraying support 31 moves longitudinally parallel to the printing platform...

Embodiment 2

[0066] This embodiment discloses a storage method, which stores a plurality of the above-mentioned printing devices that are convenient for storage, and the steps include:

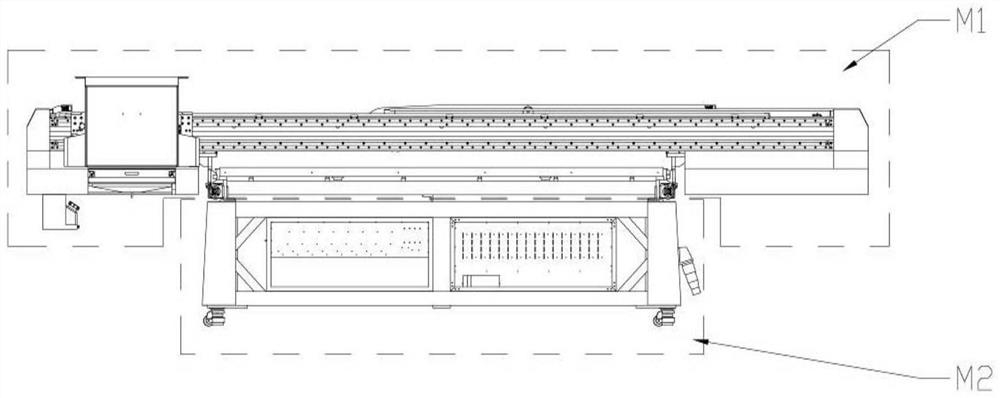

[0067] S1. Separate the intermediate platform 2 and the base 1 of each printing equipment; because the spraying vehicle 3 is connected to the intermediate platform 2, separating the intermediate platform 2 and the base 1 is to separate the entire printing equipment into two modules M1 and M2, including the spraying vehicle The first module M1 of the intermediate platform, the second module M2 including the base;

[0068] S2. Put the intermediate platform M1 of multiple printing devices on top of each other for spraying and dislocation;

[0069] S3. Lay the bases M2 of multiple printing devices in a stacked manner or vertically arrange them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com