Intelligent variable-speed adjusting and material detecting and processing device for mining belt conveyor

A belt conveyor, variable speed adjustment technology, applied in conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of falling off, uneven distribution, slow belt conveying speed, etc., and achieve the effect of avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

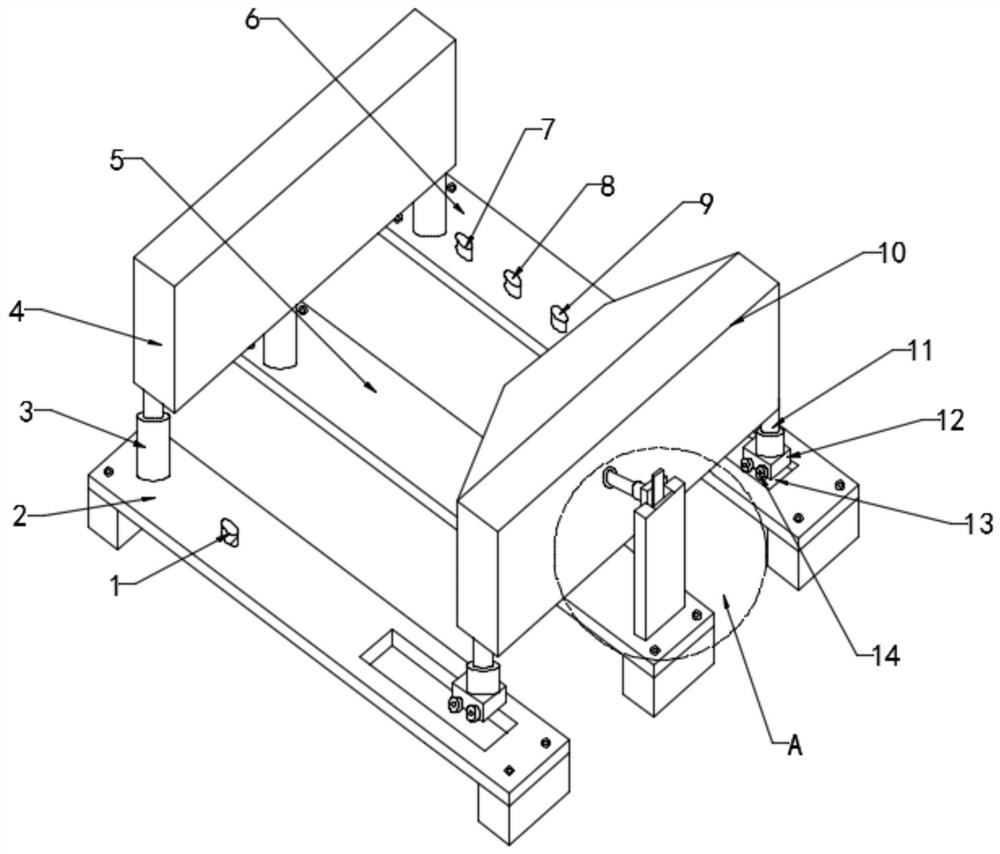

[0021] see figure 1 , in Embodiment 1 of the present invention, an intelligent variable speed adjustment and material detection and processing device for a belt conveyor for mining, which includes: a bottom plate, a first block 4 and a second block 10, and the first block 4 passes through the second block An electric telescopic rod 3 is movably installed on the upper end of the base plate, and the lower end of the second block 10 is movably installed on the upper end of the base plate through the second electric telescopic rod 11. A push assembly is provided on one side of the second block 10; a photoelectric speed measuring device is provided on the base plate instrument 1 and a laser rangefinder;

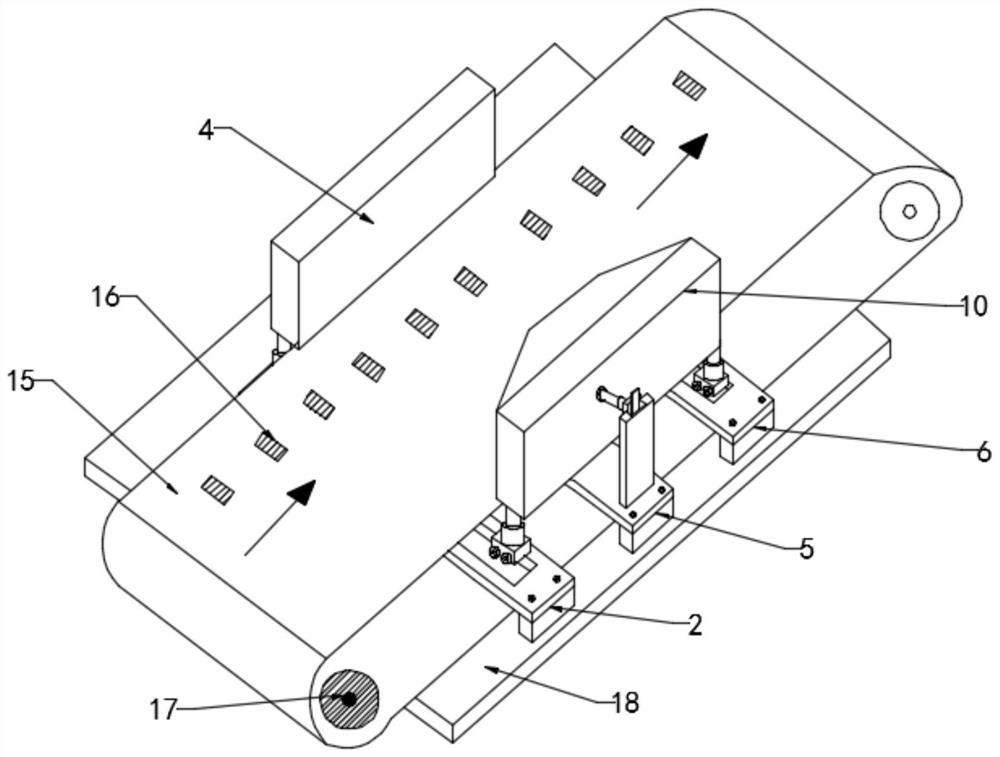

[0022] see figure 2 , the bottom plate is installed on the conveyor frame 18, and when the conveyor belt 15 circulates through the cooperation of the driving wheel and the driven wheel 17 to transport mineral materials, the surface of the conveyor belt 15 is provided at interval...

Embodiment 2

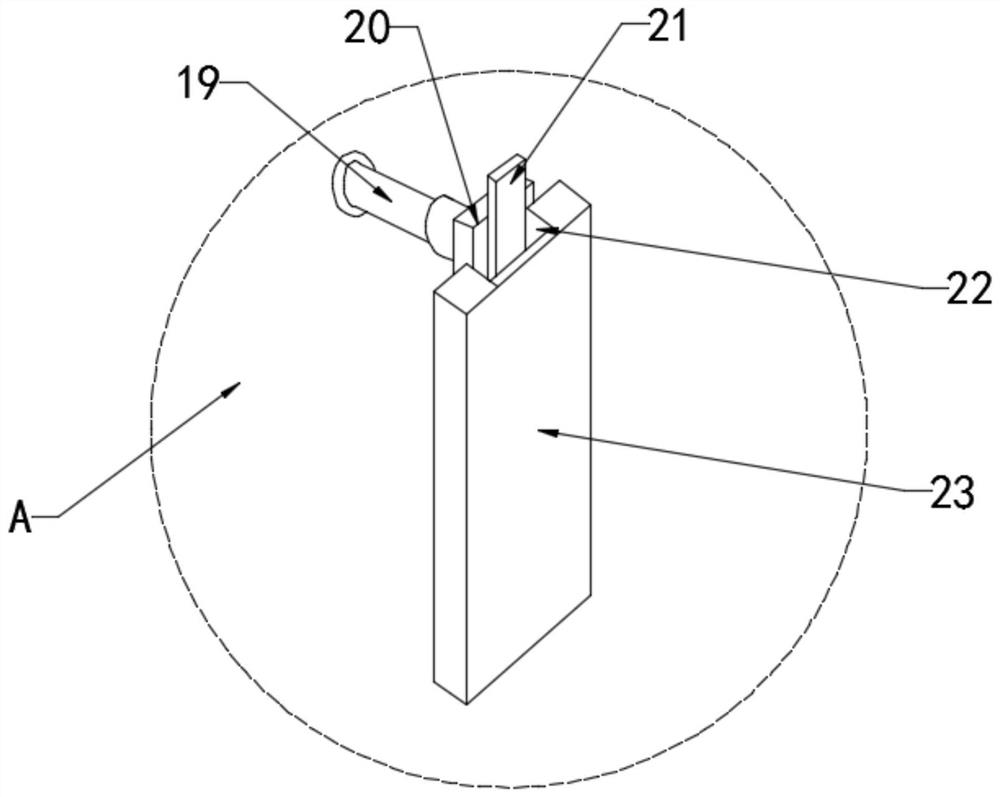

[0028] see image 3 , further, at A, the pushing assembly includes a hydraulic telescopic rod 19, a hydraulic cylinder 20 and a limit block 21, one end of the hydraulic telescopic rod 19 is connected to the second block 10, and the other end of the hydraulic telescopic rod 19 is provided with a hydraulic cylinder 20. A limit block 21 is provided on one side of the hydraulic cylinder 20;

[0029] Specifically, the upper end of the second bottom plate 5 is provided with a vertical plate 23, and a limiting groove 22 is opened inside the vertical plate 23, and the limiting block 21 provided on one side of the hydraulic cylinder 20 is movable and installed in the limiting groove inside the vertical plate 23. 22 in;

[0030] Furthermore, one end of the first bottom plate 2 and one end of the third bottom plate 6 are provided with a chute 13, the lower end of the second electric telescopic rod 11 is provided with a slider 12, and the lower end of the slider 12 is hinged and movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com